LNG fuel powered ship filling method

A power and fuel technology, applied in the field of LNG fuel powered ship filling, to reduce the required time, save time, and solve the effect of natural gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

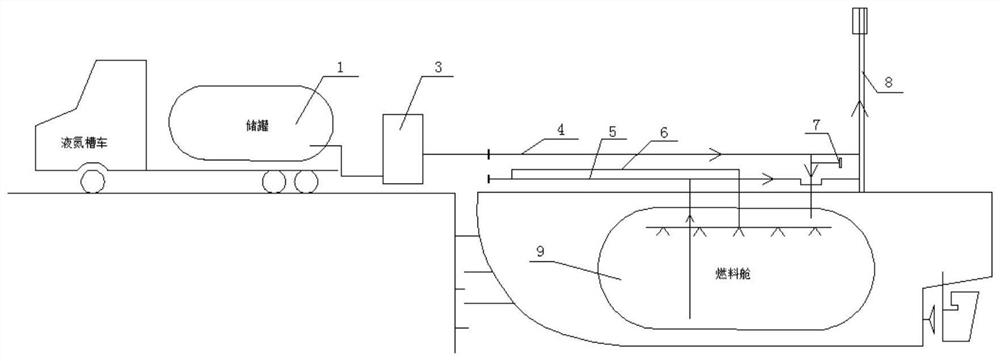

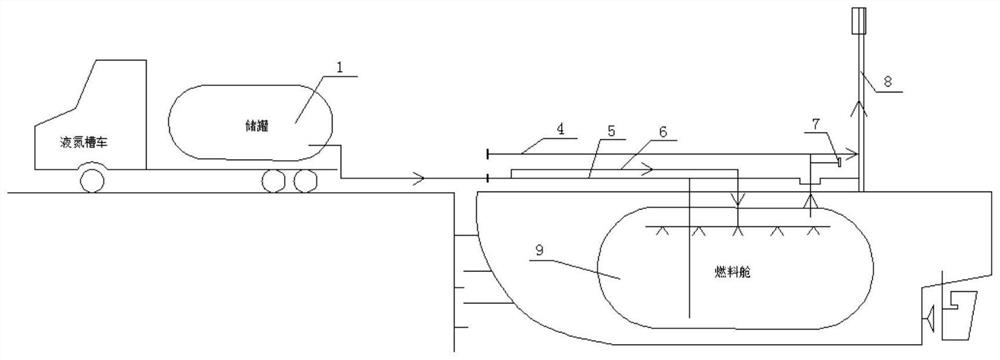

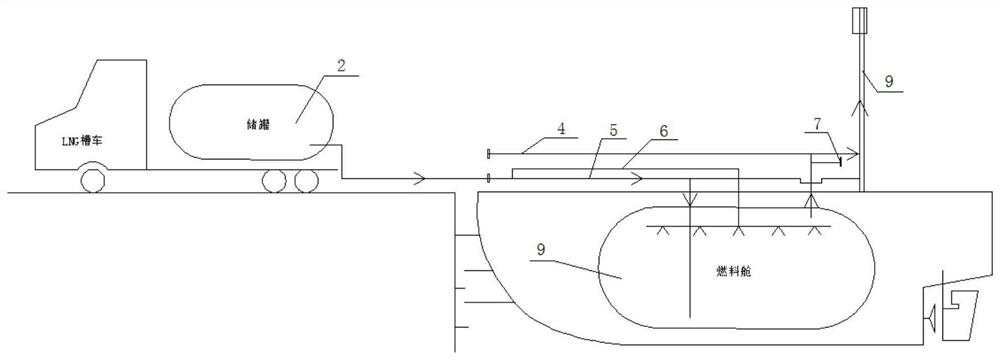

[0026] The technology and method of the present invention will be described in detail below in conjunction with the examples and accompanying drawings. The following examples and accompanying drawings are used to illustrate the composition of the present invention, but are not intended to limit the scope of the present invention.

[0027] A filling method for an LNG fuel-powered ship (taking tanker filling as an example), the method uses liquid nitrogen to spray the fuel tank during the pre-cooling process, and the LNG loading condition is reached after the liquid nitrogen pre-cooling is completed, specifically Steps include drying and inerting of fuel tanks, pre-cooling, LNG bunkering, e.g. Figure 4 shown.

[0028] Use dry nitrogen to replace the air in the fuel tank, and simultaneously dry and inert the fuel tank; when the drying and inerting are completed, the oxygen content in the fuel tank is less than 2%, and the dew point is less than -40°C.

[0029] Use liquid nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com