Industrial robot clamping device for palletizing articles

An industrial robot and palletizing technology, applied in the field of palletizing robots, can solve the problems of incorrect clamping position, unable to meet the requirements of use, falling items, etc., to achieve the effect of enhancing the clamping force, enhancing the safety, and improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

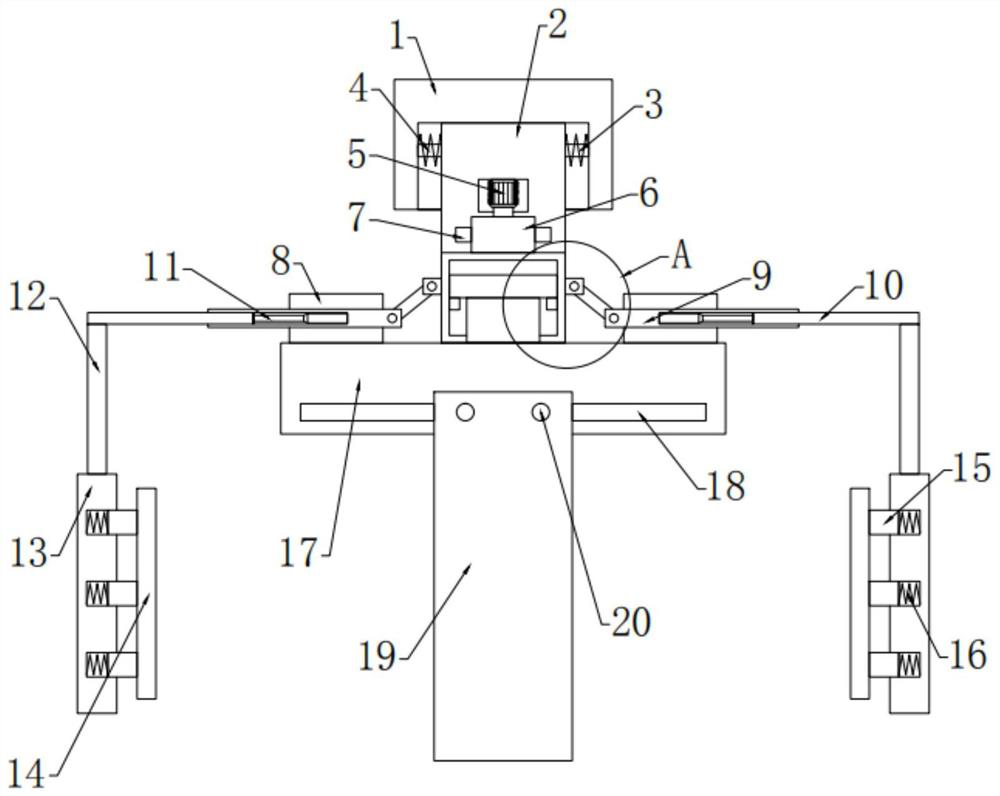

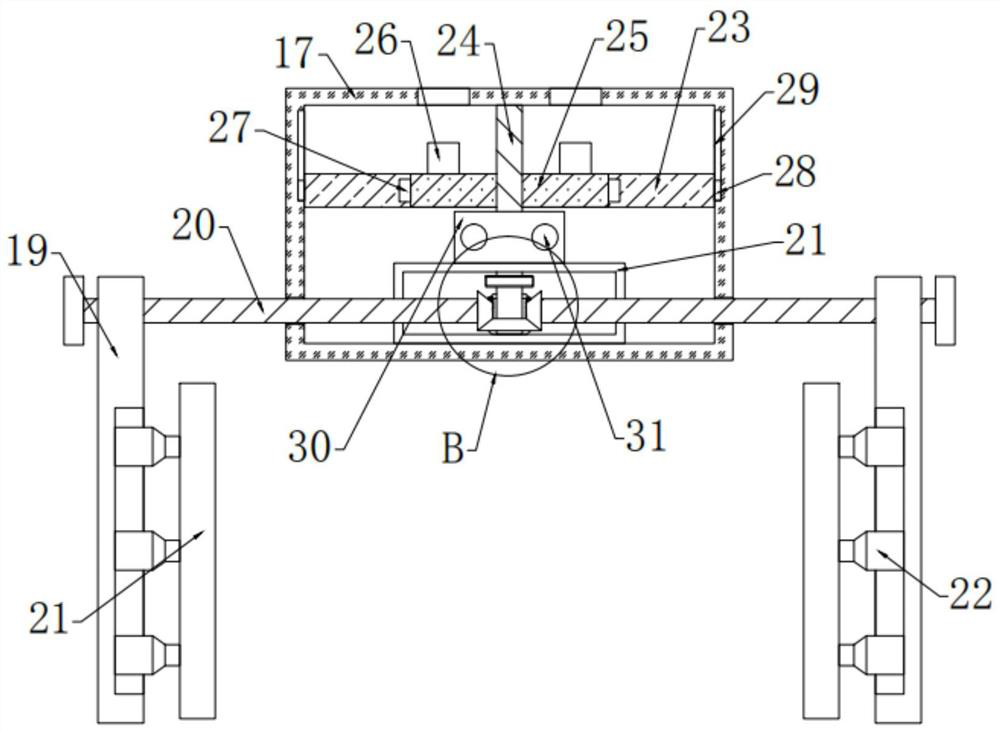

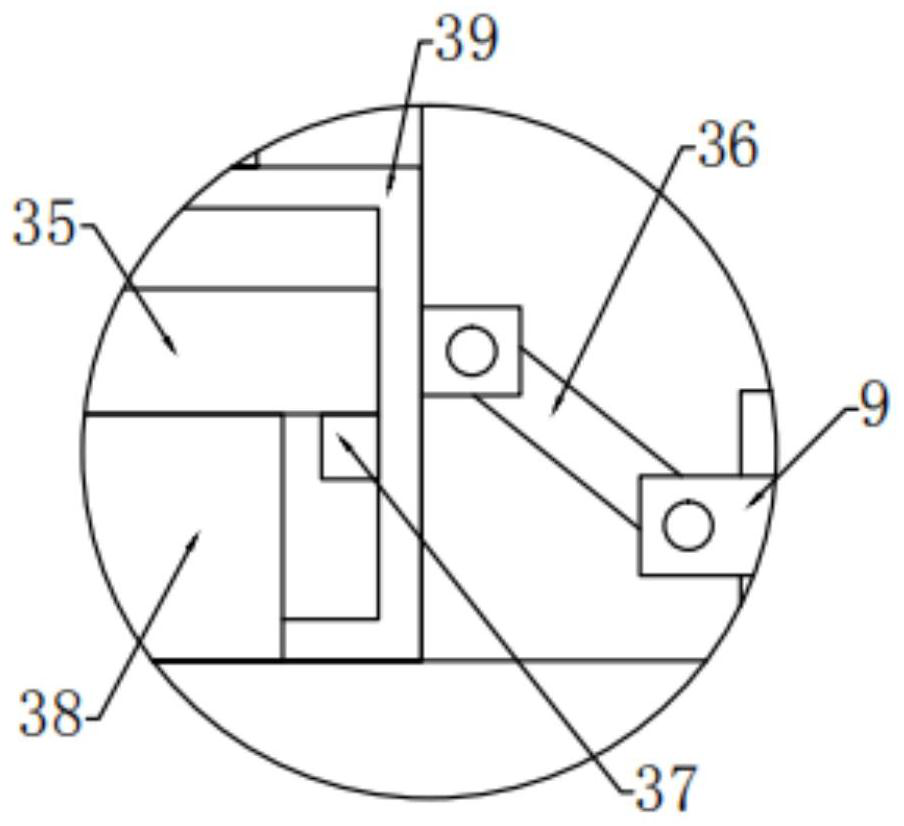

[0026] see Figure 1-5 , in an embodiment of the present invention, an industrial robot gripping device for palletizing articles includes a housing 17, the top of the housing 17 is fixedly connected with a connecting block 39, and the left and right sides of the connecting block 39 A positioning mechanism is provided, the top of the connecting block 39 is provided with a mounting mechanism, the front and rear sides of the housing 17 are provided with fixing mechanisms, and the fixing mechanism is connected with the positioning mechanism through a transmission mechanism.

Embodiment 2

[0028] In this embodiment, the installation mechanism includes an installation block 1 for connecting with the palletizing robot, the inside of the installation block 1 is fixedly connected with a limit rod 3, and the outside of the limit rod 3 is slidably connected with a movable block 2 A first spring 4 is fixedly connected between the left and right ends of the movable block 2 and the installation block 1, the inner side of the movable block 2 is bolt-connected and provided with a first motor 5, and the output end of the first motor 5 is fixedly connected to The connecting rod 7 arranged on the top of the connecting block 39 is fixedly connected. By setting the installation mechanism, the position of the clamping device can be fine-tuned by using the first spring 4 and the movable block 2, so that the device can better clamp the article. By setting the first motor 5, the clamping direction of the device can be adjusted, which is beneficial to improve the accuracy of the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com