Rotating disc type automatic assembly line

A turntable and assembly line technology, applied in metal processing equipment, climate sustainability, final product manufacturing, etc., can solve the problems of low utilization rate of equipment, high manual use, space occupation, etc., to improve utilization rate, reciprocate Use steady, consistent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

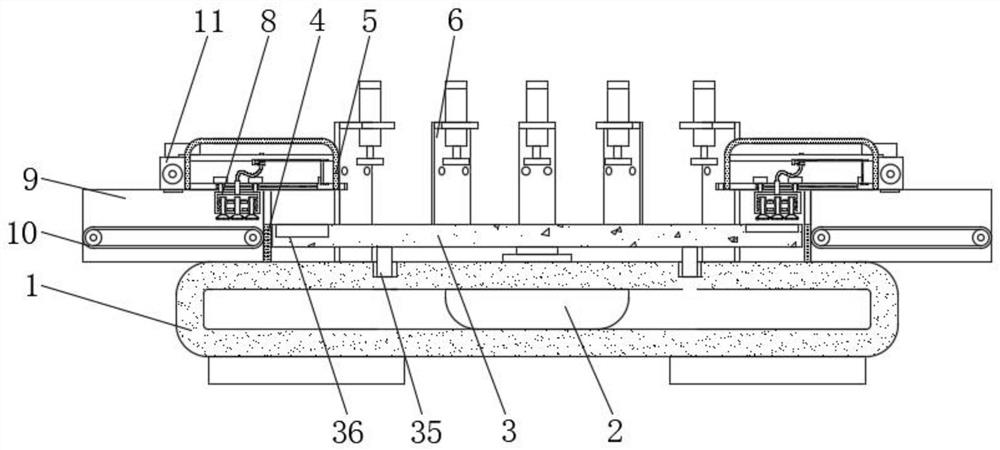

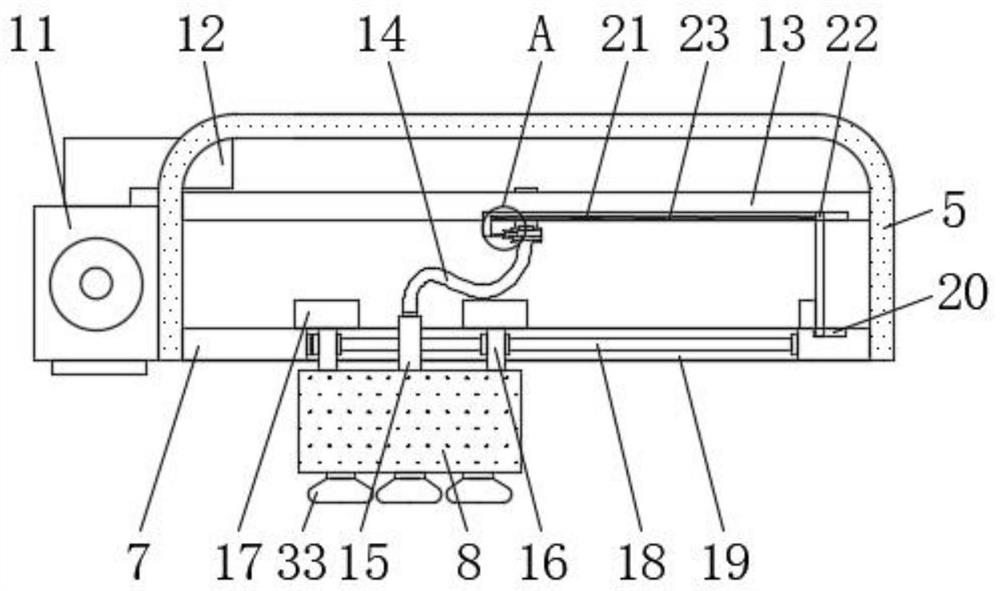

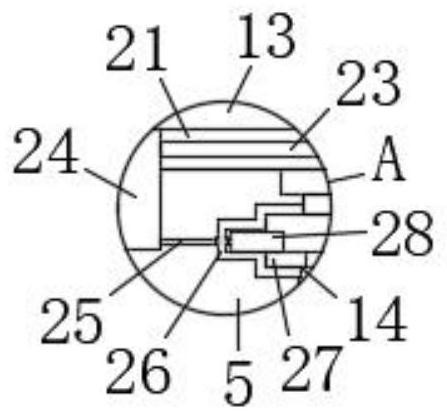

[0026] like Figure 1-5 As shown, the present invention provides a technical solution: a turntable automatic assembly line, comprising a box body 1, the upper surface of the inner wall of the box body 1 is fixedly connected with the upper surface of the drive mechanism 2, and the output shaft of the drive mechanism 2 is fixedly connected with the lower surface of the turntable 3. , the upper surface of the box body 1 is fixedly connected with the lower surface of the support plate 4, the front and back of the inner wall of the support plate 4 are fixedly connected with the front and back of the protective box 5, and the inner wall of the protective box 5 is clamped with a baffle 7 and a partition Plate 13, the lower surface of the protective box 5 is fixedly connected with the upper surface of the two card plates 9, the opposite surfaces of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap