A high-efficiency test device for diaphragm material pressure

A testing device and diaphragm technology, which is used in measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure. , Improve the adjustment accuracy and facilitate the effect of manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0028] This embodiment provides a high-efficiency test device for the pressure of the diaphragm material. Just by observing whether there is oil or gas discharged from the overflow port, it can be judged whether the diaphragm material meets the use requirements. The test device is small in size and easy to operate , which greatly improves the pressure test efficiency of the diaphragm material.

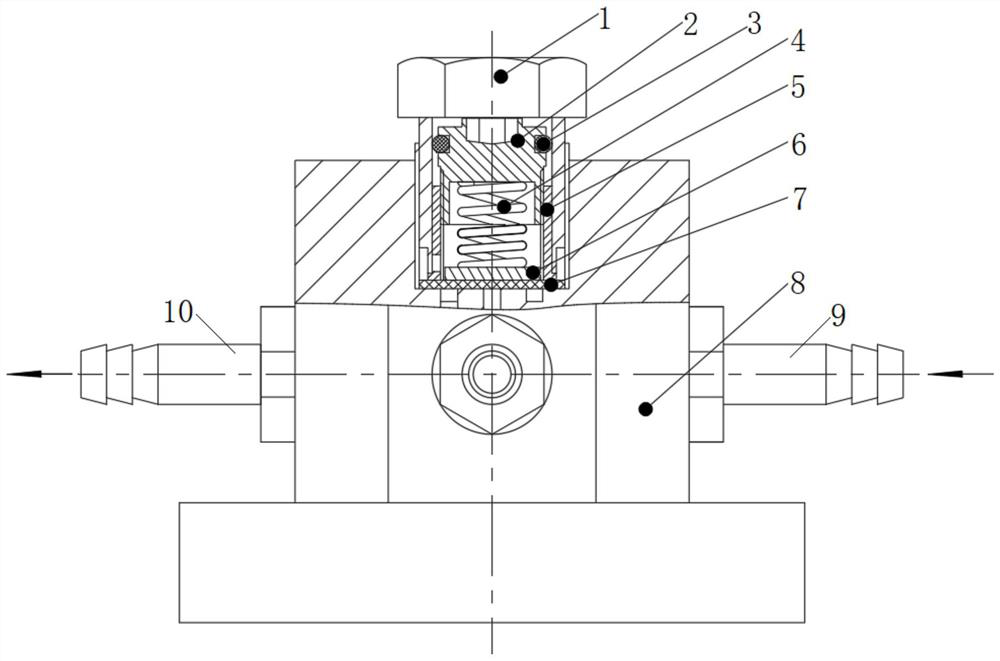

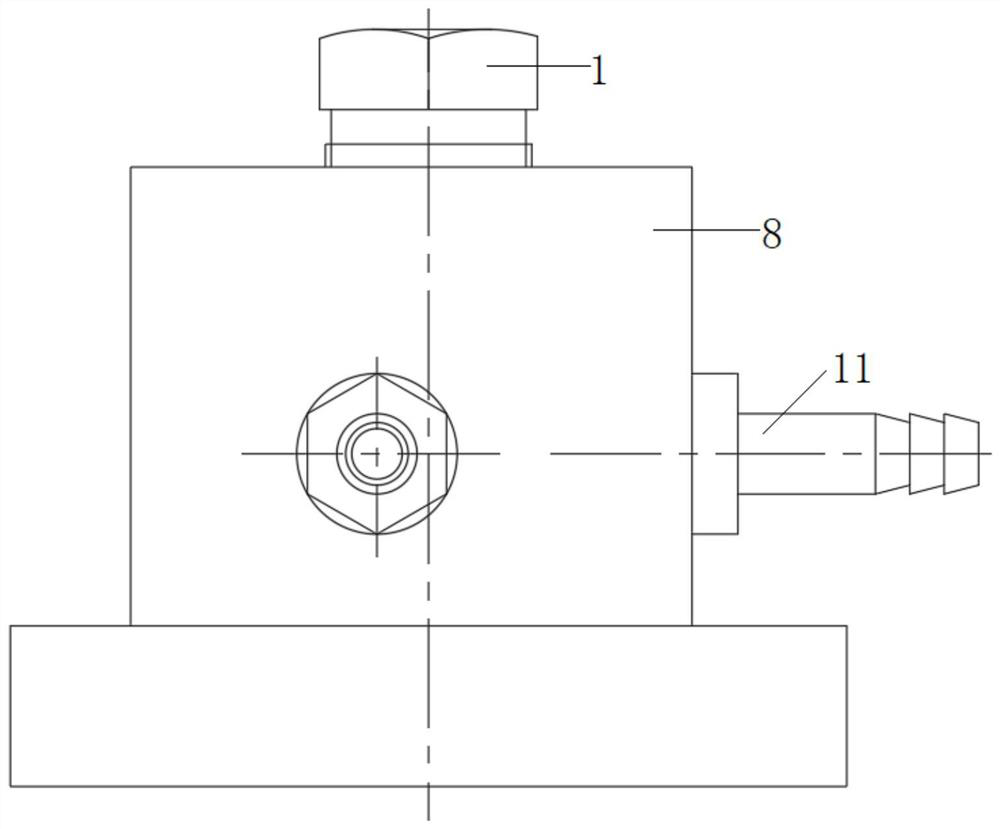

[0029] Such as Figure 1-3 As shown, the test device includes: a fastening bolt 1, an adjusting bolt 2, a spring 4, a valve body 5, a copper pad 6, a device body 8, an air inlet pipe 9, an air outlet pipe 10 and an overflow pipe 11.

[0030] The connection relationship of the test device is as follows: Figure 4-7 As shown, the device body 8 is a stepped cylindrical structure, the large end of which is used as the test device base, and the small end is machined w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com