Blade damping test bench

A test bench and blade technology, used in vibration testing, mechanical component testing, machine/structural component testing, etc., can solve the influence of blade damping characteristics, the study of frictional motion laws, and changes in blade damping characteristics are not considered. and other issues to achieve the effect of improving the technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that: any technical feature and any technical solution in this embodiment are one or more of a variety of optional technical features or optional technical solutions. All the alternative technical features and alternative technical solutions of the present invention are cited, and it is not convenient for the implementation of each technical feature to emphasize that it is one of the optional multiple implementation modes, so those skilled in the art should know: Any technical features and any technical solutions in the embodiments do not limit the protection scope of the present invention, and the protection scope of the present invention should include any alternative technical solutions that those skilled in the art can think of without creative efforts.

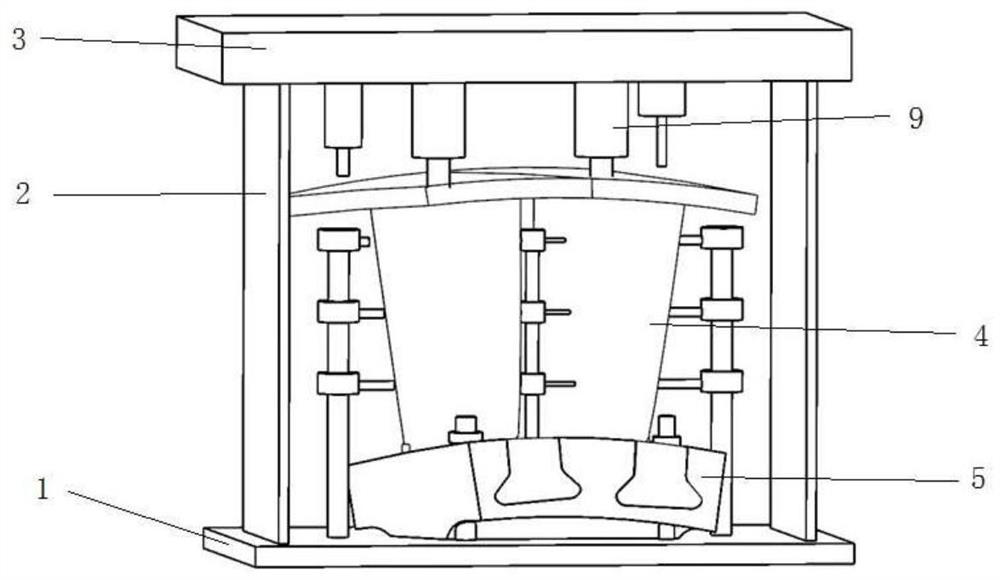

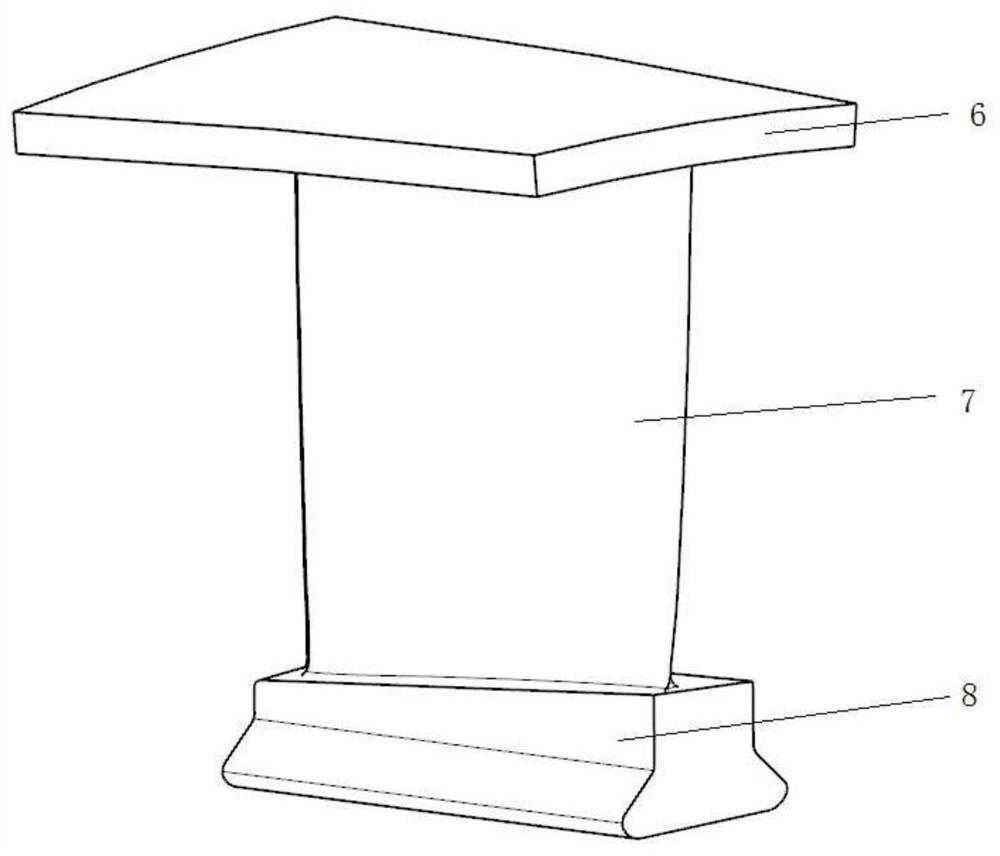

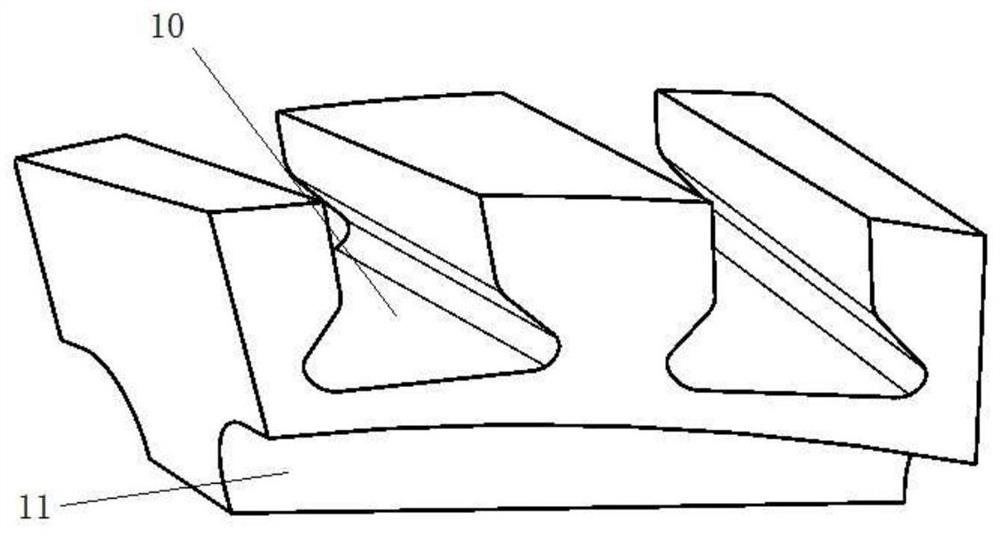

[0026] see figure 1 , a blade damping test bench provided by the present invention includes a base frame, a blade wheel disk fixing device, a blade shroud fixing device, an excitation loading dev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap