Hall ion source and discharge system thereof

A Hall ion source and ion source technology, applied in discharge tubes, ion beam tubes, circuits, etc., can solve the problems of difficult ion implantation and deposition coating, uneven treatment of the inner wall of the tube, etc., to reduce self-sputtering and realize sputtering The uniformity and the effect of increasing the ionization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

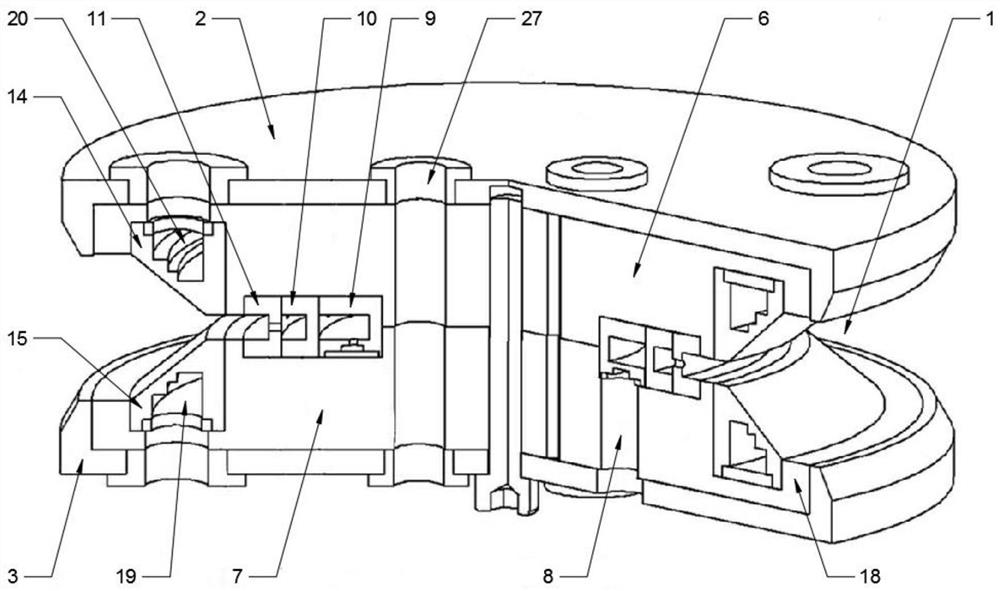

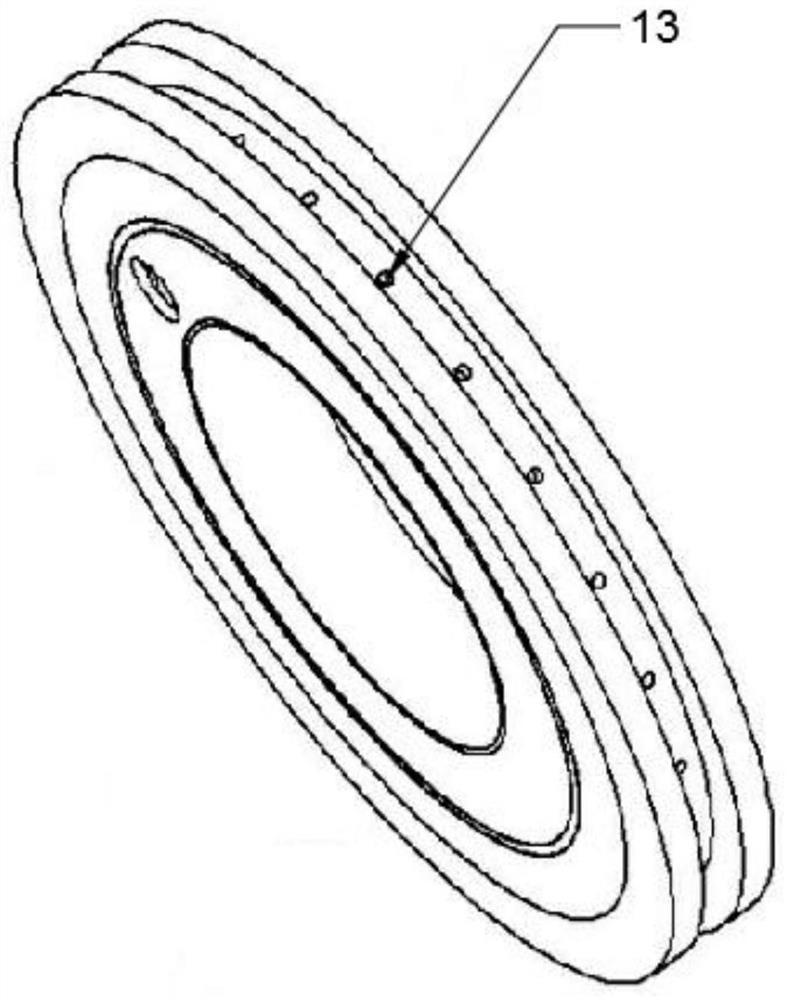

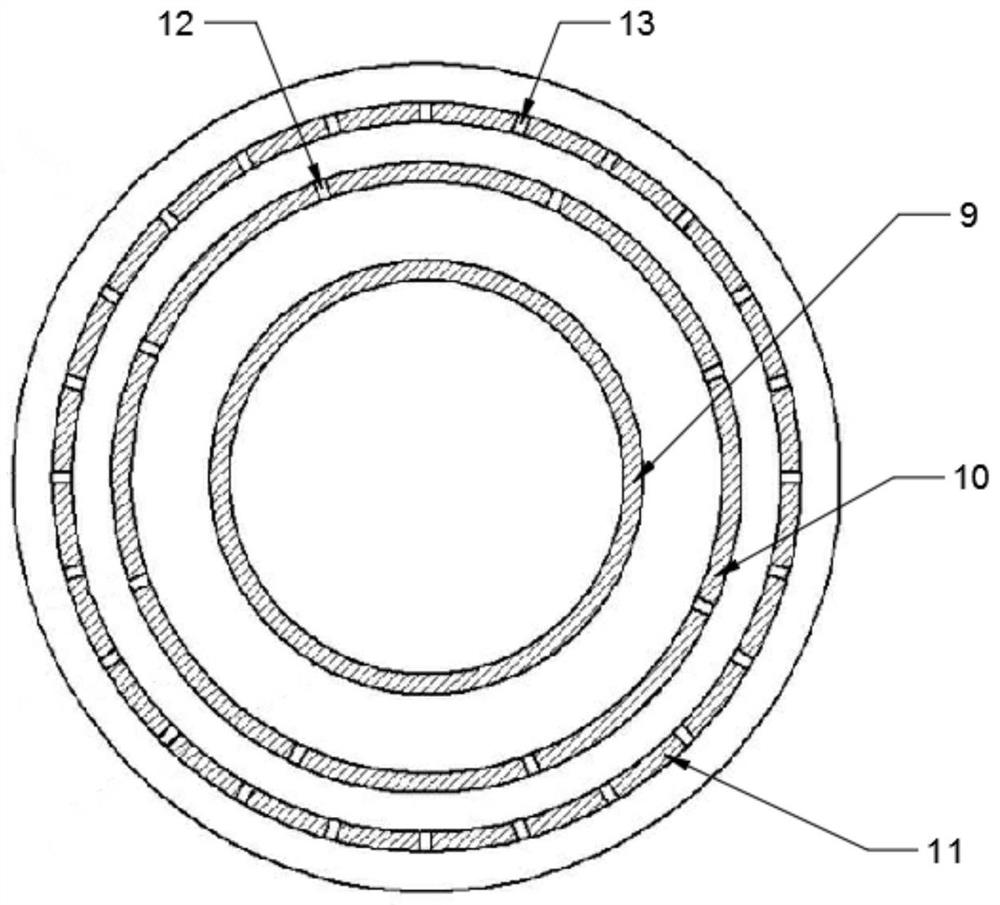

[0040] Such as Figure 1 to Figure 5 As shown, a Hall ion source includes a device body; the device body is made of insulating material and has a circular structure, and a notch 1 is provided on the outside; the two sides of the device body are respectively provided with first magnetic poles 2 and the second magnetic pole 3; the middle part of the device body is provided with a first permanent magnet 4 and a second permanent magnet 5 which are symmetrical to each other and pass through the device body and the two magnetic poles.

[0041]In this embodiment, the device body is composed of two parts, namely the first body 6 and the second body 7, and the first body 6 and the second body 7 are insulating materials; when the first body 6 and the second bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com