Impurity removing device capable of adapting to aluminum coils with different thicknesses

A technology for removing devices and impurities, applied in the field of impurity removing devices, can solve the problems of low cleaning efficiency, poor practicability, and complicated operation, and achieve the effect of improving efficiency and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

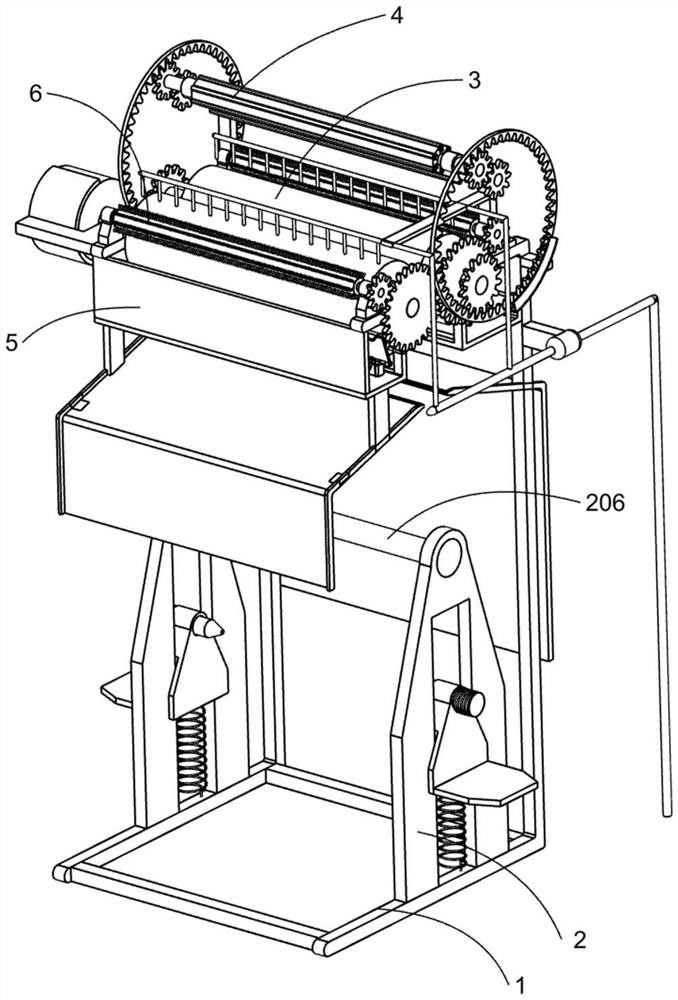

[0024] An impurity removal device capable of adapting to aluminum coils of different thicknesses, such as Figure 1-10 As shown, it includes a support 1, a water pump 101, a water suction pipe 102, a support plate 103, a water spray pipe 104, a drainage board 105, a drainage board 2 106, a placement mechanism 2, a cleaning mechanism 3, a transmission mechanism 4 and an extrusion mechanism. 5. The water pump 101 is fixed on one side of the upper part of the support 1, the water suction pipe 102 is fixed on one end of the water pump 101, and the placement mechanism 2 for placing aluminum coils is set on the lower part of the support 1. The cleaning mechanism 3 for removing impurities on the aluminum coil is arranged on the upper part of the support 1, and the transmission mechanism 4 for transmitting the aluminum coil is arranged on the support 1 and connected with the cleaning mechanism 3, The support plate 103 is arranged on the transmission mechanism 4, two parallel water spr...

Embodiment 2

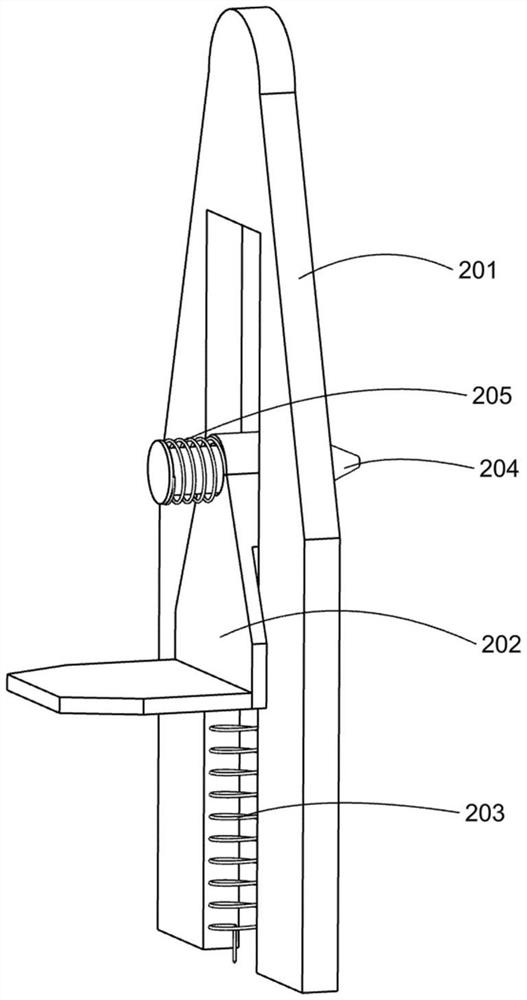

[0032] On the basis of Example 1, such as figure 1 , Figure 5 and Figure 9-10 As shown, the extruding mechanism 5 for extruding the sewage on the two cleaning sponge rollers 301 in time includes a second mounting plate 501, an extruding roller 502, a fixed seat 1 503, a torsion spring 504 and an extruding plate 505, The upper part of the support 1 is fixedly provided with two mounting plates 2 501 and the drainage plate 2 106 is fixed on the bottom side of one of the mounting plates 2 501, and both mounting plates 2 501 are rotatably provided with extrusion rollers 502 and The two squeeze rollers 502 are in contact with the two cleaning sponge rollers 301 respectively, and the two squeeze rollers 502 are used to carry out a preliminary extrusion operation on the sewage of the two cleaning sponge rollers 301. Seat one 503, the extrusion plate 505 is rotatably arranged on the fixed seat one 503 and is in contact with the cleaning sponge roller 301, and the two extrusion plat...

Embodiment 3

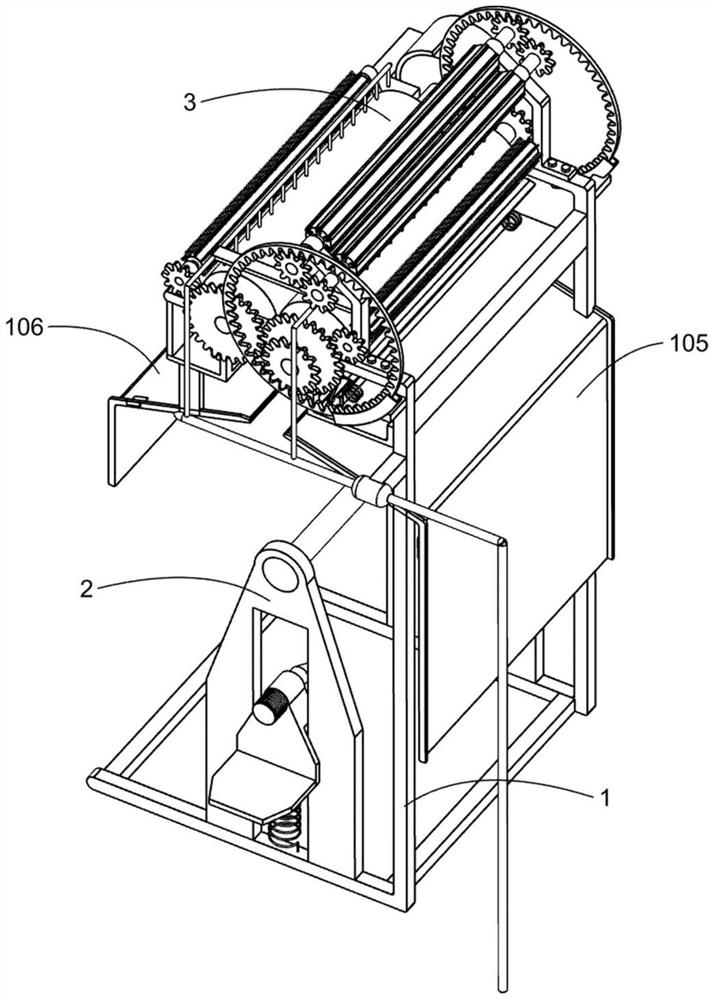

[0035] On the basis of Example 2, such as figure 1 , Figure 5 and Figure 10 As shown, it also includes a cleaning mechanism 6 for cleaning the impurities on the two cleaning sponge rollers 301. The cleaning mechanism 6 is arranged on the support 1 and the two mounting frames 404. The cleaning mechanism 6 includes a fixed seat 2 601 , Cleaning roller 602 and power gear 603, the upper part of described support 1 is fixed on two sets of symmetrical fixed seats 601, and the fixed seats 2 601 of the two groups are all rotatably provided with for cleaning the sponge roller 301. The cleaning roller 602 of operation, two cleaning rollers 602 contact with two cleaning sponge rollers 301 respectively, and one end of two described cleaning rollers 602 is all fixedly provided with power gear 603 and two power gears 603 mesh with two transmission gears 302 respectively.

[0036] Working process: one of the transmission gears 302 will drive the power gear 603 meshed with it to rotate co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com