A kind of modified fly ash adsorbent and preparation method thereof, and adsorption method of trimethylamine

A technology for fly ash and adsorbent, which is applied in separation methods, chemical instruments and methods, and other chemical processes to achieve the effects of increasing adsorption capacity, enhancing stability, and improving load rate and load uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

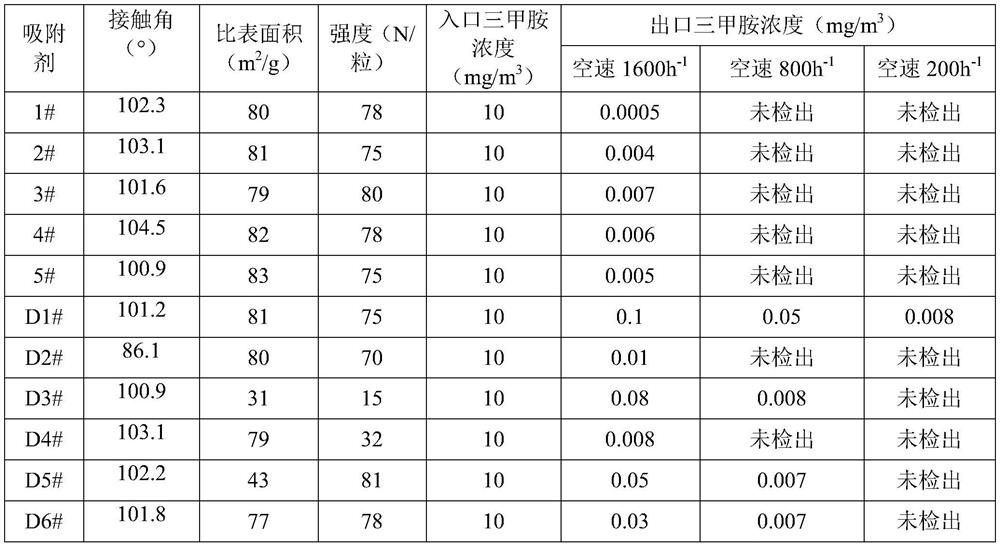

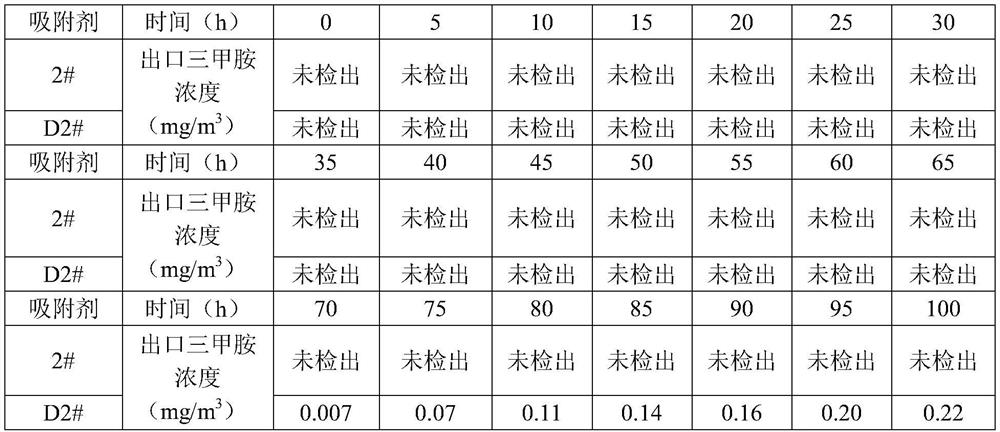

Examples

Embodiment 1

[0036] (1), grind the collected fly ash into fine powder, after passing through an 80-mesh sieve, leave the fine powder passing through the sieve to wash and dry, get 200g of fine powder, add 120g of bentonite and 224g of distilled water, mix well and then extrude, Then, the pretreated adsorbent was obtained by calcining at 500 °C for 3 h;

[0037] (2), take 200g of pretreated adsorbent, add a total of 400mL of 10wt% hydrogen peroxide solution, sonicate for 2h under 120Hz ultrasonic condition, then take out and dry at 100°C for 4h to obtain hydrogen peroxide modified adsorbent;

[0038] (3), prepare a mixed solution containing ferric nitrate, copper nitrate, cobalt nitrate, nickel nitrate and ammonium fluoride, wherein the mass fractions of Fe, Cu, Co, and Ni are 2wt%, 1.5wt%, 3wt%, 2wt% respectively , the mass fraction of F is 2 wt%, 600 mL of mixed solution was added to 200 g of the adsorbent modified with hydrogen peroxide, sonicated for 3 h under 80 Hz ultrasonic condition...

Embodiment 2

[0041] (1), grind the collected fly ash into fine powder, after passing through a 160-mesh sieve, leave the fine powder passing through the sieve to wash and dry, get 200g of fine powder, add 160g of bentonite and 216g of distilled water, mix well and then extrude, Then, the pretreated adsorbent was obtained by calcining at 550 °C for 4 h;

[0042] (2), take 200g of pretreated adsorbent, add a total of 500mL of 12wt% hydrogen peroxide solution, sonicate for 2.5h under 100Hz ultrasonic conditions, then take out and dry at 105°C for 4.5h to obtain hydrogen peroxide modified adsorbent;

[0043] (3), prepare a mixed solution containing iron nitrate, copper nitrate, cobalt nitrate, nickel nitrate and ammonium fluoride, wherein the mass fractions of Fe, Cu, Co, and Ni are 2.5wt%, 2.5wt%, 4wt%, 3wt%, respectively %, the mass fraction of F is 2.5 wt%, add 500 mL of mixed solution to 200 g of the adsorbent modified with hydrogen peroxide, sonicate for 2.5 h under 90 Hz ultrasonic condi...

Embodiment 3

[0046] (1), the collected fly ash is ground into fine powder, after passing through a 200-mesh sieve, the fine powder passing through the sieve is washed and dried, and 200g of fine powder is taken, 140g of bentonite and 272g of distilled water are added, and after mixing, extrusion molding, Then, the pretreated adsorbent was obtained by calcining at 600 °C for 5 h;

[0047] (2), take 200g of pretreated adsorbent, add a total of 600mL of 12.5wt% hydrogen peroxide solution, sonicate for 3h under 80Hz ultrasonic conditions, then take out and dry at 110°C for 5h to obtain hydrogen peroxide modified adsorbent;

[0048] (3), prepare a mixed solution containing ferric nitrate, copper nitrate, cobalt nitrate, nickel nitrate and ammonium fluoride, wherein the mass fractions of Fe, Cu, Co, Ni are 3wt%, 2wt%, 4.5wt%, 4wt% respectively , the mass fraction of F is 3 wt%, 400 mL of mixed solution was added to 200 g of the adsorbent modified with hydrogen peroxide, sonicated for 2 h under 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com