Organic waste gas purification device

A purification device and organic waste gas technology, applied in the direction of gas treatment, transportation and packaging, chemical instruments and methods, etc., can solve the problems of increased floor area, cumbersome waste gas treatment, low efficiency, etc., and achieve the effect of improving the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

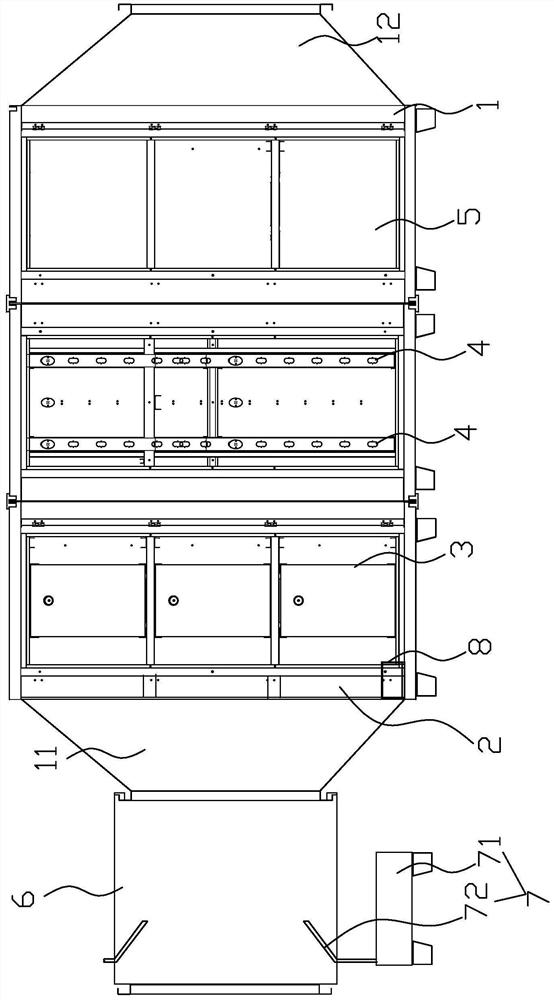

[0011] refer to figure 1 , the preferred organic waste gas purification device of the present invention includes a box body 1, a large particle filter assembly 2, a first activated carbon filter assembly 3, a second activated carbon filter assembly 4, a UV photolysis assembly 5, a suction fan, a connecting pipe 6, a blower Gas mechanism 7 and vibrator 8, the box body 1 is divided into three spaces in turn from left to right, and the left side is the exhaust gas inlet 11, and the right side is the discharge outlet 12, and the large particle filter assembly 2 includes a plurality of filter cotton And the first grid frame for accommodating multiple pieces of filter cotton, the multiple pieces of filter cotton are filled in the first grid frame, the first grid frame is vertically arranged in the box body 1 at the exhaust gas inlet 11 on the left side, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com