River snail rice noodle chili oil packaging bag sealing device

A sealing device and chili oil technology, applied in packaging sealing/fastening, packaging, transportation packaging and other directions, can solve problems such as unalignment, bag mouth extrusion, affecting the sealing effect and sealing aesthetics, etc., to avoid unaligned, ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

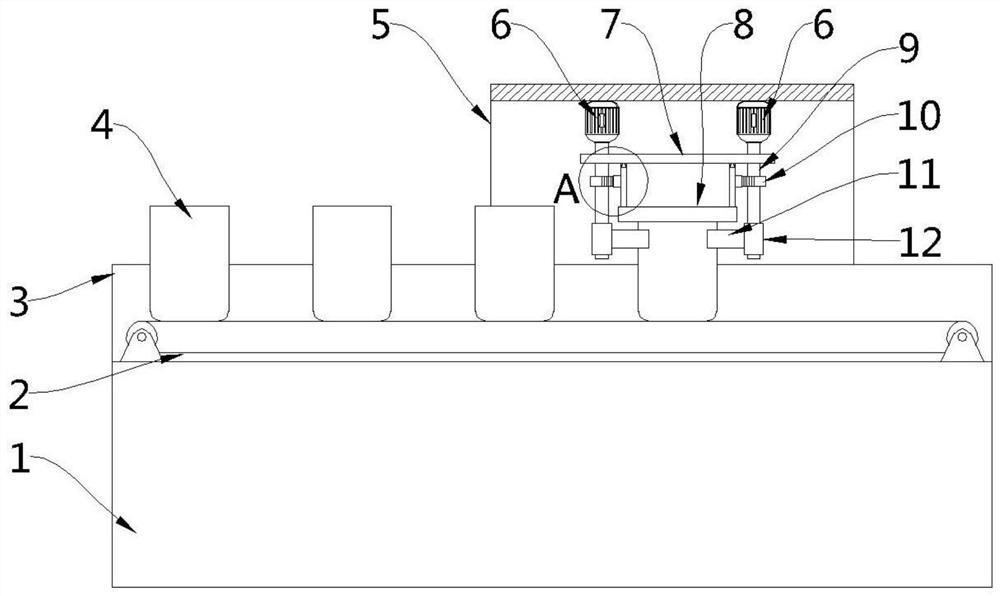

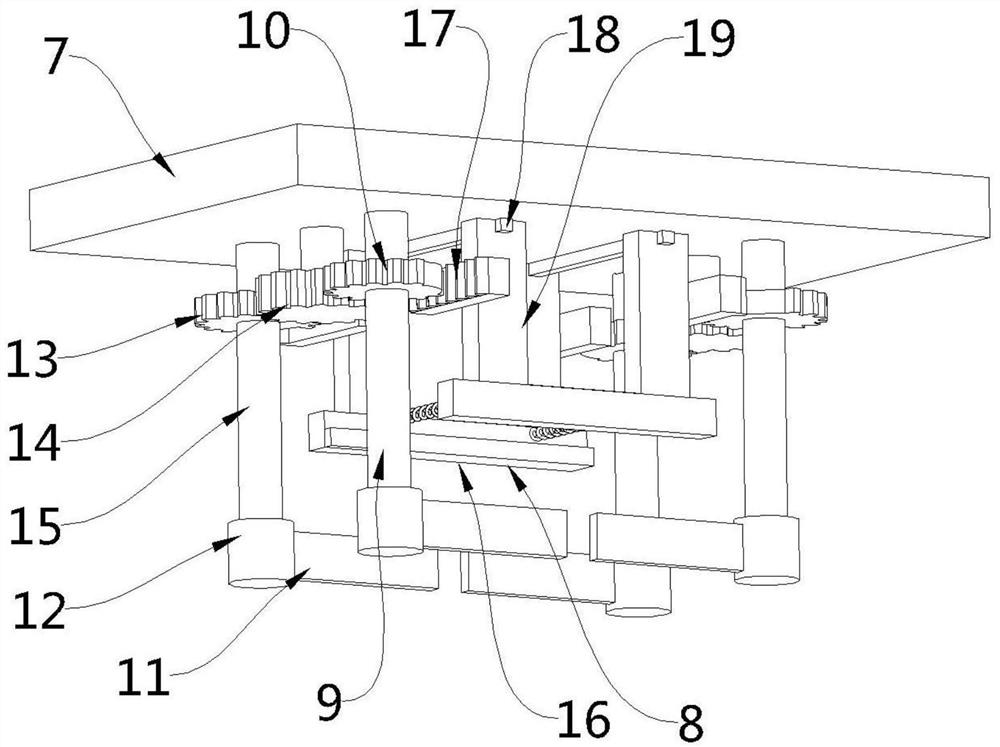

[0024] Example 1

[0025] see Figure 1-4 , the present embodiment provides a sealing device for packaging bags of snail powder and chili oil, including a bottom box 1, a conveying assembly 2 is installed on the upper part of the bottom box 1, a sealing box 5 is fixedly arranged on the upper part of the bottom box 1, and the sealing box 5 A sealing assembly is installed inside. Specifically, the sealing assembly includes two sets of motors 6 that are fixedly installed on the inner top of the sealing box 5 and a driving shaft 9 that is fixedly connected to the output ends of the two sets of motors 6. The two sets of motors 6. Distributed at intervals along the conveying direction of the conveying assembly 2, the driving shaft 9 is vertically distributed, the driving half-gear 10 is also fixedly arranged on the driving shaft 9, and a horizontally distributed fixing plate 7 is also fixedly arranged inside the sealing box 5 , the bottom of the fixed plate 7 is rotatably provided ...

Example Embodiment

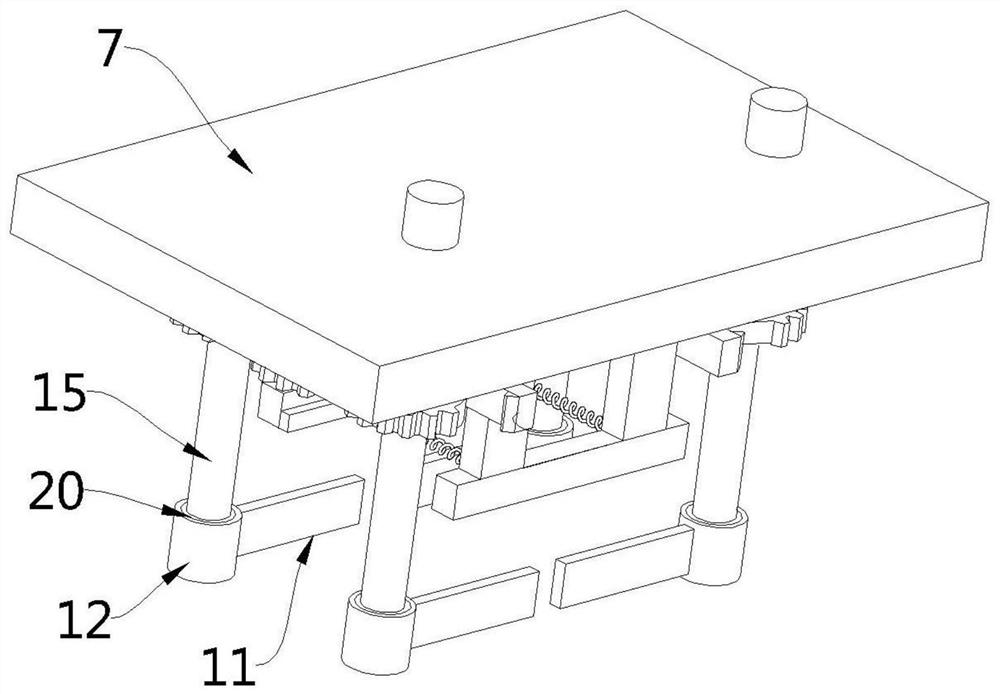

[0032] Example 2

[0033] see image 3 , A sealing device for packaging bags of snail powder and chili oil. Compared with Embodiment 1, the sleeve 12 is rotatably matched with the corresponding driving shaft 9 and the driven shaft 15, and the sleeve 12 is rotatably matched with the corresponding driving shaft 9. A damping ring 20 is also provided between the shaft 9 and the driven shaft 15. Through the setting of the damping ring 20, when the four groups of clamping and pulling plates 11 clamp and tighten the sides of the bag body 4, the driving shaft 9 and the With the continuous rotation of the driven shaft 15, the sleeve 12 can rotate relative to each other, which can prolong the clamping time of the pinch plate 11 for the bag body 4, thereby ensuring that the heat sealing knife 15 can have enough time to heat seal the bag mouth.

[0034] Specifically, the damping ring 20 is made of rubber material.

[0035] In the embodiment of the present invention, before sealing, four s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap