Preparation method and wine brewing method of vinasse distiller's yeast

A technology of distiller's yeast and waste, which is applied in the preparation of distiller's yeast and its brewing field, which can solve the problems of increasing the cost of raw material input, and achieve the effects of cost savings, high-efficiency utilization, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of distiller's grains, comprising the following steps:

[0031] After inoculating Rhizopus oryzae on the PDA medium and culturing for 48-72 hours, it was observed that obvious blue-black spores appeared on the surface of the mycelium. The spores were eluted with sterile water to obtain a spore liquid, which was inoculated into sterilized bran and cultivated at 30°C. After a large number of hyphae appear, they are dried / dried and crushed to obtain bran koji. Take a small part of the crushed standard sample and measure its glucoamylase activity by Fehling's reagent method at 1091.2U / g.

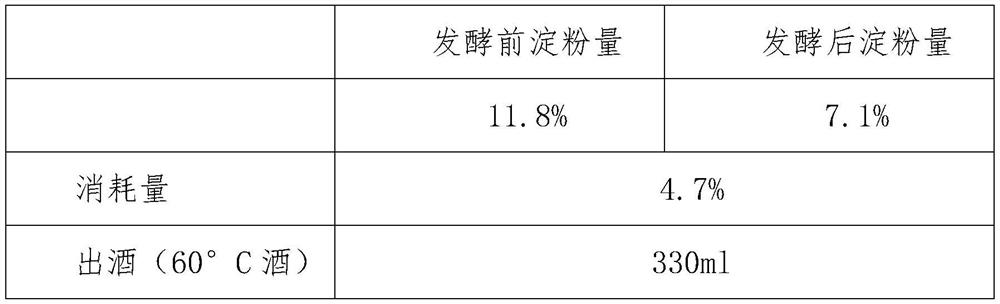

[0032] Five grains of sorghum, corn, rice, glutinous rice and wheat are used as raw materials in the following mass ratio: 36% sorghum, 8% corn, 22% rice, 18% glutinous rice and 16% wheat are mixed as raw materials. The raw material is crushed and sieved through a 100-mesh sieve, gelatinized, and the ratio of gelatinized material to water is controlled at 1:9 to obt...

Embodiment 2

[0039]A preparation method of distiller's grains, comprising the following steps:

[0040] After inoculating Aspergillus niger AS3.4309 on PDA medium and culturing for 48-72 hours, it was observed that black spores appeared on the surface of mycelia. The spores were eluted with sterile water to obtain a spore liquid, which was inoculated into sterilized bran and cultivated at 30°C. After a large number of hyphae appear, they are dried / dried and crushed to obtain bran koji. Take a small part of crushed standard sample and measure its glucoamylase activity by Fehling's reagent method, which is 1285.7U / g.

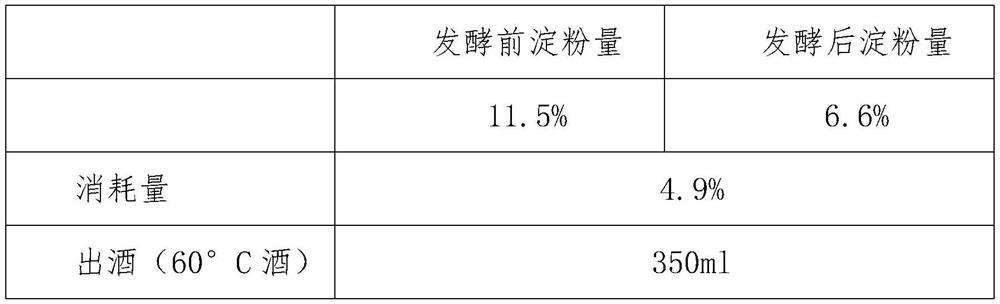

[0041] Five grains of sorghum, corn, rice, glutinous rice and wheat are used as raw materials in the following mass ratio: 36% sorghum, 8% corn, 22% rice, 18% glutinous rice and 16% wheat are mixed as raw materials. The raw material is crushed and sieved through a 100-mesh sieve, gelatinized, and the ratio of gelatinized material to water is controlled at 1:9 to obtain a yea...

Embodiment 3

[0048] A preparation method of distiller's grains, comprising the following steps:

[0049] After inoculating Aspergillus niger AS3.4309 on PDA medium and culturing for 48-72 hours, it was observed that black spores appeared on the surface of mycelia. The spores were eluted with sterile water to obtain a spore liquid, which was inoculated into sterilized bran and cultivated at 30°C. After a large number of hyphae appear, they are dried / dried and crushed to obtain bran koji. Take a small part of crushed standard sample and measure its glucoamylase activity by Fehling's reagent method, which is 1285.7U / g.

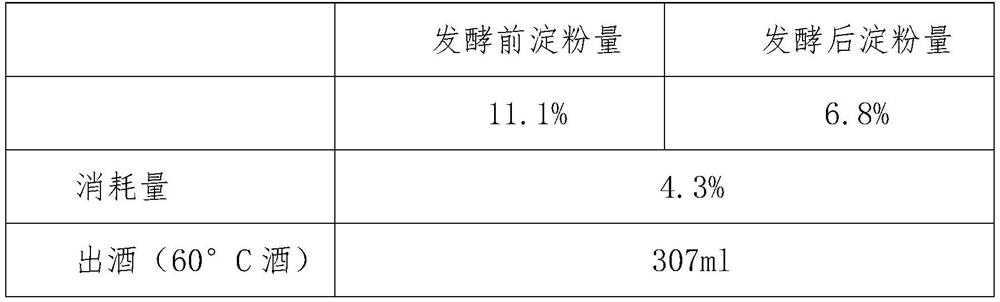

[0050] Sorghum is used as raw material to be crushed, sieved through a 100-mesh sieve, and gelatinized. The ratio of gelatinized material to water is controlled at 1:9 to obtain a yeast expansion culture medium. Weigh 1% of commercially available Xiaoqu and add it in, stir evenly and seal it, and culture it at 30°C for 48 hours to obtain the expansion culture solution. Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com