Positive electrode active material, positive pole piece, electrochemical energy storage device and new energy automobile

A positive electrode active material and particle size technology, which is applied in the field of electrochemical energy storage devices and new energy vehicles, positive electrode active materials, and positive electrode sheets, can solve the problem of poor cycle performance, intensified side reactions between ternary materials and electrolytes, and inability to Fully meet the needs of lithium-ion battery energy density and other issues, to achieve the effect of reducing gas production and side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

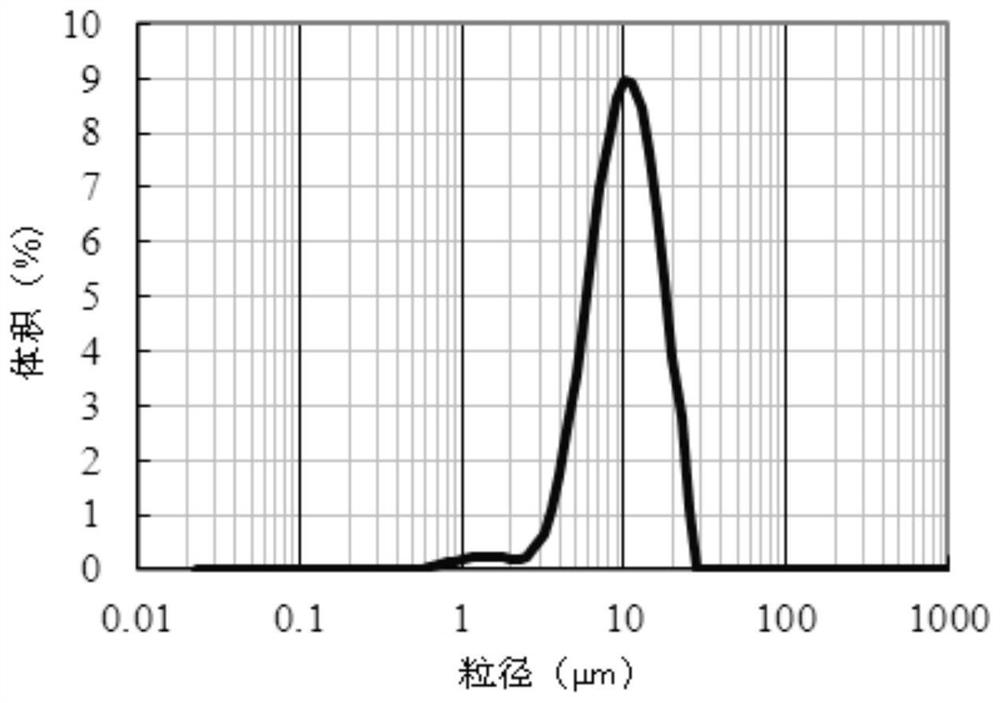

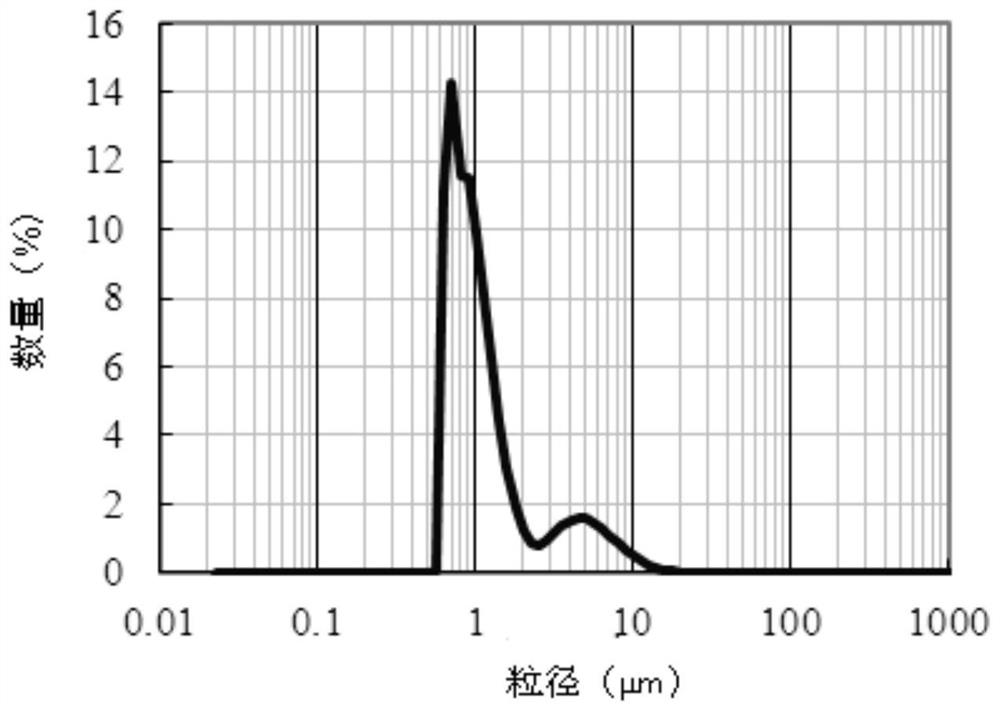

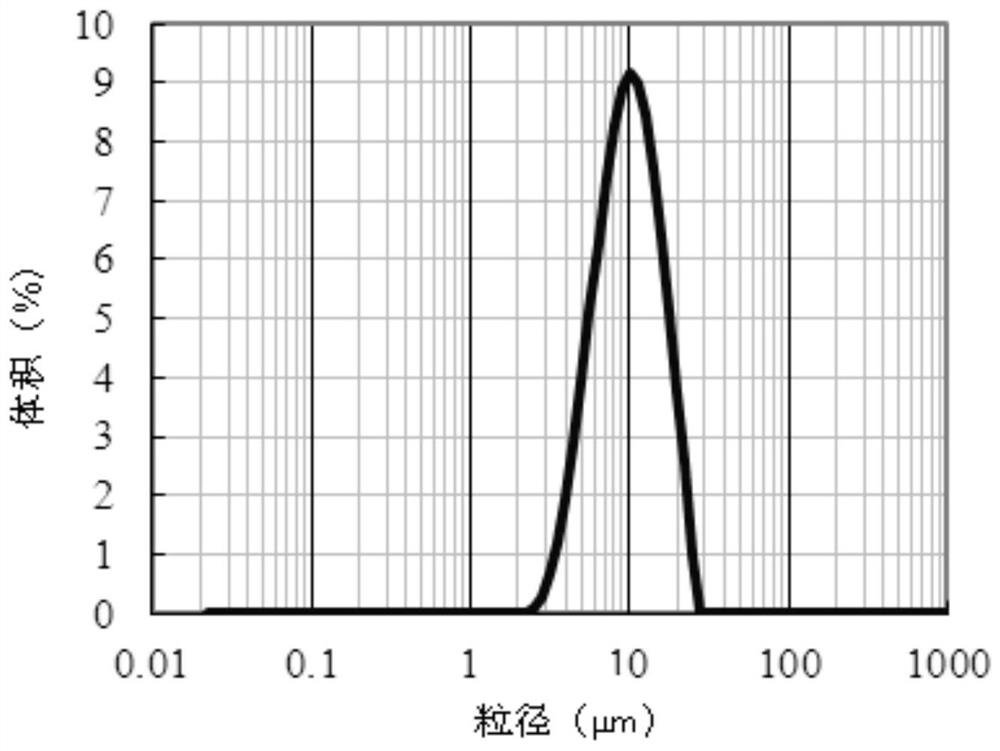

Image

Examples

preparation example Construction

[0042] Next, a preparation method of the positive electrode active material according to the second aspect of the application is described, which is used to prepare the positive electrode active material described in the first aspect of the application, which includes the steps of: making the ternary material precursor (containing Ni, Co and M compound), Li-containing compound, compound containing doping element Me, and compound containing doping element A are placed in a mixing equipment for mixing, and then placed in an atmosphere furnace for sintering. After sintering, it is classified and screened to obtain Positive active material.

[0043] Wherein, the hierarchical screening method is not particularly limited, and can be selected according to actual conditions. Preferably, the grading screening can be selected from air-flow grading screening or sieve screening.

[0044] The specific process of air classification and screening is as follows: put the sintered material int...

Embodiment 9

[0088] The lithium ion battery of Example 9 was prepared according to the following method.

[0089] (1) Preparation of positive electrode active material

[0090] The ternary material precursor Ni 0.8 co 0.1mn 0.1 (OH) 2 , LiOH·H 2 O, ZrO 2 Place it in a blender for mixing with a molar ratio of 0.997:1.05:0.003, and then place it in an atmosphere furnace full of oxygen for primary sintering; mix the material after primary sintering with 0.5wt% Al 2 o 3 Place in a mixing device for mixing, and then place in an atmosphere furnace for secondary sintering; then classify and sieve the material after the secondary sintering to select a suitable particle size to obtain Li(Ni 0.8 co 0.1 mn 0.1 ) 0.997 Zr 0.003 o 2 The surface is provided with Al 2 o 3 positive electrode active material.

[0091] (2) Preparation of positive pole piece

[0092] Mix the above-mentioned positive electrode active material, binder polyvinylidene fluoride, and conductive agent acetylene blac...

Embodiment 10

[0101] The lithium ion battery of embodiment 10 is prepared according to the method similar to the lithium ion battery of embodiment 9, the difference is that 0.5wt% Al 2 o 3 Replaced with 0.5wt% B 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com