Turbine blade crack welding repair method capable of refining structure

A welding repair, turbine blade technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of uneven thermal cycle process, high thermal crack sensitivity, mechanical performance reduction, etc., to improve structure and crystallization condition, reduce residual stress, promote grain refinement and control the effect of microstructure transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

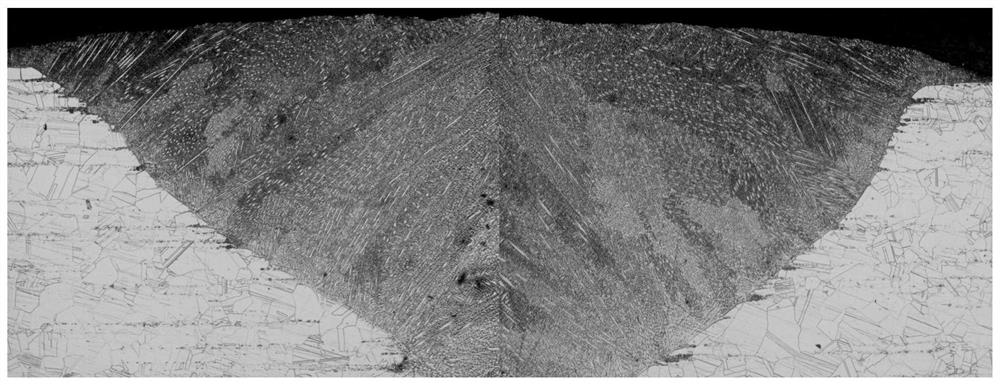

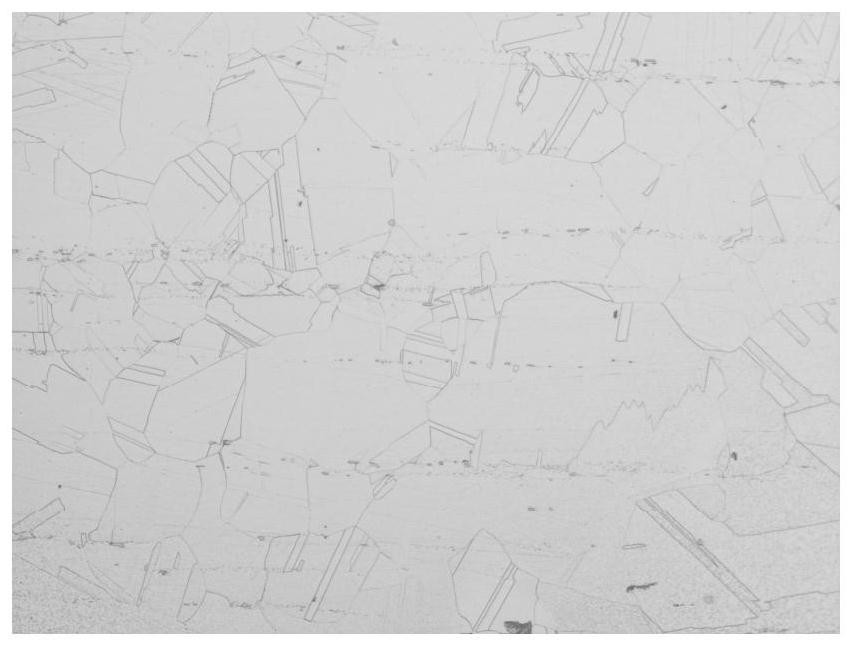

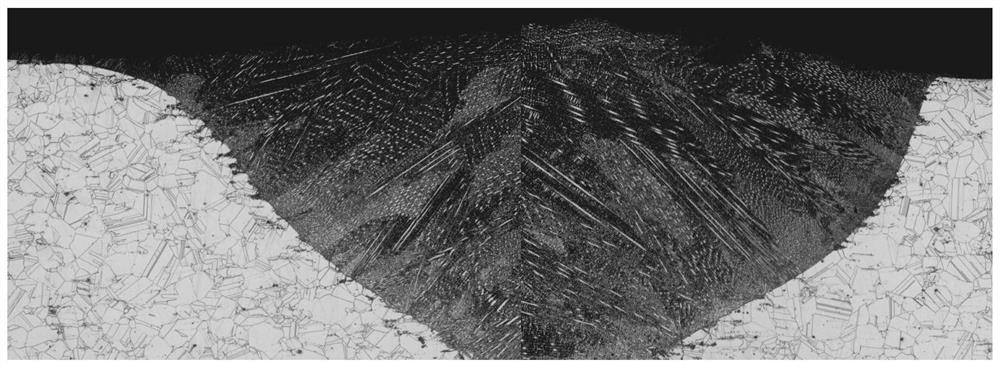

[0021] The invention provides a turbine blade crack welding repair method that can refine the structure. The laser-arc hybrid welding method is used to repair the turbine blade crack welding. Multiple independently controlled induction heating coils, and the whole welding process is under inert gas protection.

[0022] The welding process parameters of laser-arc hybrid welding are as follows: laser power 3500W, arc voltage 18V, current 90A, welding speed 0.9m / min, wire feeding speed 2m / min, wire diameter 0.9mm, during the whole welding process, the flow rate of inert shielding gas is 2L / min, the atmosphere pressure is 200MPa; in the preheating stage before welding, control the current in multiple induction coils to keep the same, so that the crack defect position is heated to 600°C within 50mm above and below, and keep warm for 45min; in the welding stage, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com