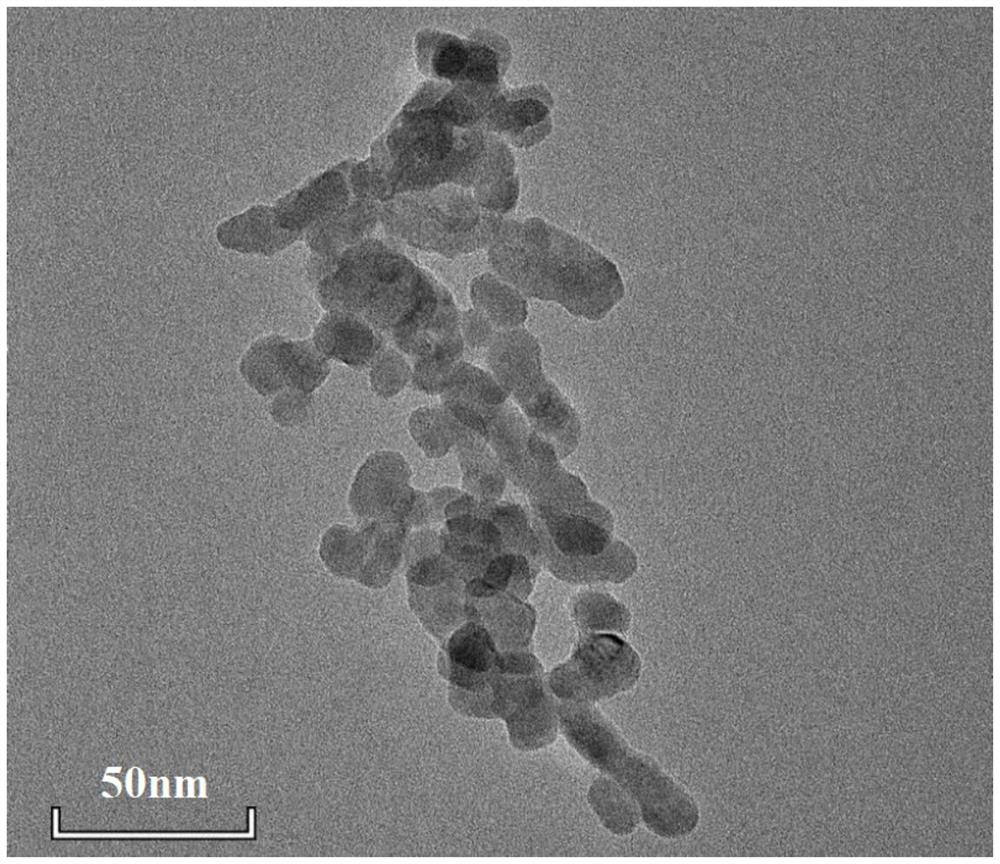

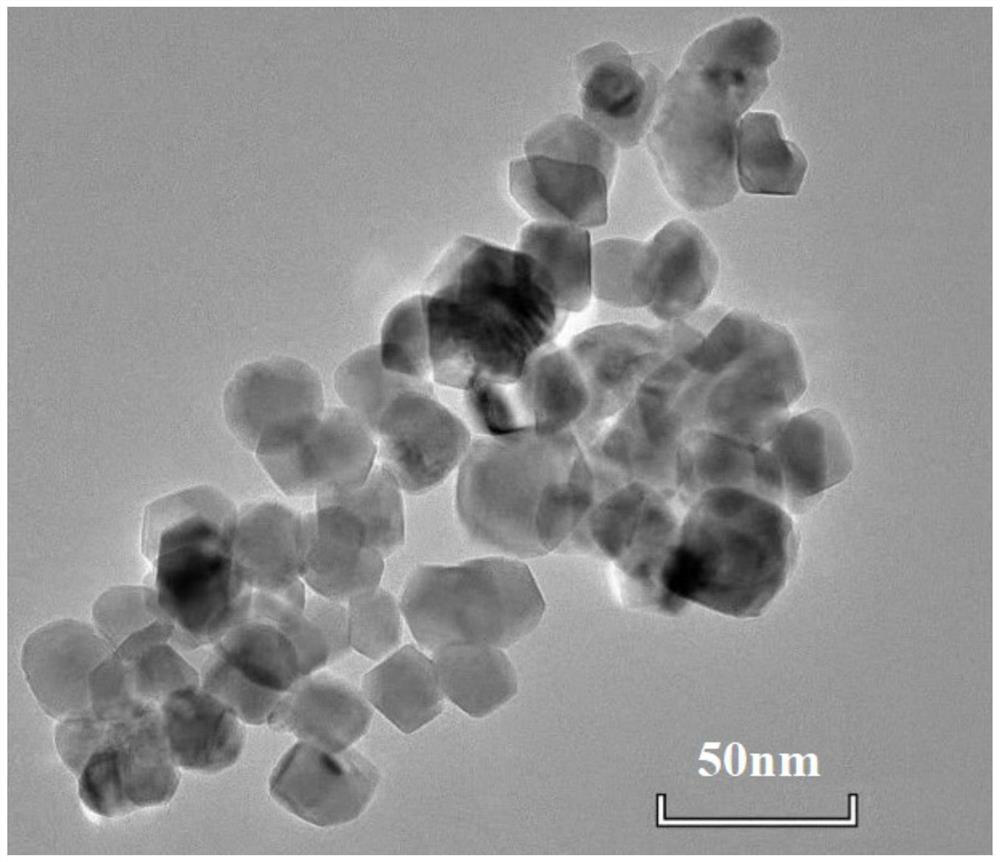

A method for surface modification of nano-calcium carbonate with particle size less than 20nm

A technology for nano-calcium carbonate and surface modification, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for materials and surface science. It can solve difficult problems such as nano-calcium carbonate modification, and achieve reliable and effective solutions. Effect of small, low hydroxyl content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

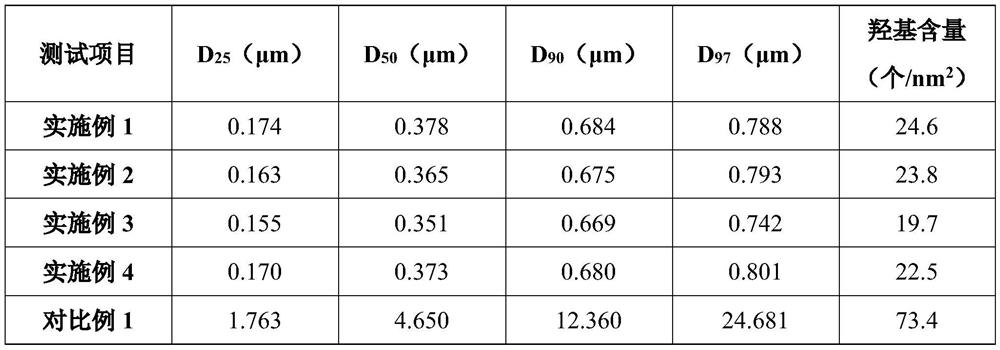

Embodiment 1

[0034] A method for surface modification of nano-calcium carbonate with a particle diameter less than 20nm, comprising the following steps:

[0035] 1) The average particle size is 18nm, the BET specific surface area is 117m 2 The nanometer calcium carbonate of / g adds water dispersion and makes the suspension of mass fraction 10%, then the suspension is transferred to reactor;

[0036] 2) Add barium chloride with 0.5% of the quality of nano-calcium carbonate into the reaction kettle, and stir for 30 minutes;

[0037] 3) Add polyethylene glycol with 5% nano-calcium carbonate quality into the reaction kettle, the number-average molecular weight of polyethylene glycol is 700g / mol, heat up to 85°C, and stir at constant temperature for 90min;

[0038] 4) Add sodium hydroxide to the reaction kettle to adjust the pH of the reaction solution in the reaction kettle to 9.5, then add itaconic acid with 4% nanometer calcium carbonate quality, stir for 25min, then add 0.05% nanometer cal...

Embodiment 2

[0040] A method for surface modification of nano-calcium carbonate with a particle diameter less than 20nm, comprising the following steps:

[0041] 1) The average particle size is 14nm, the BET specific surface area is 134m 2 The nanometer calcium carbonate of / g adds water dispersion and makes the suspension of mass fraction 10%, then the suspension is transferred to reactor;

[0042] 2) Add barium chloride with 1% nano-calcium carbonate quality into the reaction kettle, and stir for 30 minutes;

[0043] 3) Add polyethylene glycol with 8% nano-calcium carbonate quality into the reaction kettle, the number-average molecular weight of polyethylene glycol is 800g / mol, heat up to 85°C, and stir at constant temperature for 90min;

[0044] 4) Add sodium hydroxide to the reactor to adjust the pH of the reaction solution in the reactor to 9.5, then add itaconic acid with a mass of 6% of nano-calcium carbonate, stir for 25 minutes, and then add N,N-dicarbonate with a mass of 0.05% o...

Embodiment 3

[0046] A method for surface modification of nano-calcium carbonate with a particle diameter less than 20nm, comprising the following steps:

[0047] 1) The average particle size is 16nm, the BET specific surface area is 126m 2 The nanometer calcium carbonate of / g adds water dispersion and makes the suspension of mass fraction 10%, then the suspension is transferred to reactor;

[0048] 2) Add barium chloride with a quality of 0.8% of nano-calcium carbonate into the reactor, and stir for 30 minutes;

[0049] 3) Add polyethylene glycol with 8% nano-calcium carbonate quality into the reaction kettle, the number-average molecular weight of polyethylene glycol is 900g / mol, heat up to 85°C, and stir at constant temperature for 90min;

[0050]4) Add sodium hydroxide to the reactor to adjust the pH of the reaction solution in the reactor to 9, then add itaconic acid with a mass of 5% of nano-calcium carbonate, stir for 25 minutes, and then add N,N-Di Methpropylamine and dibenzoyl p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com