Cutter suction dredger bridge trunnion sleeve mounting method

A technology of a cutter suction dredger and an installation method, which is applied in the directions of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve installation and construction difficulties, narrow operable space, and difficulty in ensuring installation. Accuracy and other issues, to achieve the effect of improving the construction environment, large operating space, and meeting the installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] Taking the 3500 square cutter suction dredger as an example, the specific implementation method is as follows: including the following steps:

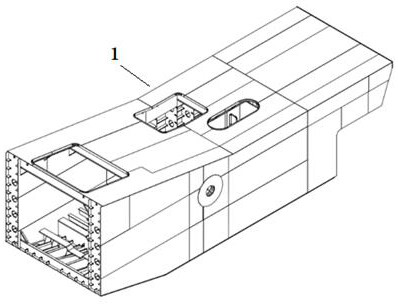

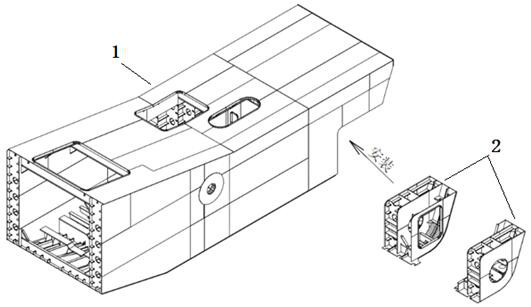

[0023] S1. When the bridge section 1 is built, the main part of the bridge section 1 is installed, and the end of the bridge section 1 is installed with the trunnion sleeve 22 to separate two independent sections 2, and the bridge section 1 is installed with the trunnion sleeve 22 The bottom of the end is vacant, as in figure 1 shown.

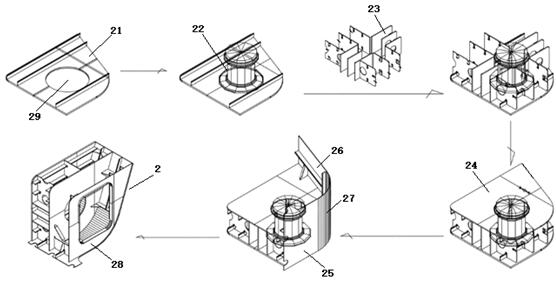

[0024] S2. Assemble the two independent sections 2. During the assembly process of the independent section 2, install the trunnion sleeve 22 into the independent section 2. During the assembly process of the independent section 2, install the trunnion sleeve 22 into the independent section. In the section 2, the independent section 2 is assembled separately, the operating space is not limited, the construction environment when the trunnion sleeve 22 is installed is improved, and the construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com