Liquid-phase coated graphite negative electrode material and preparation method thereof

A graphite negative electrode, liquid phase coating technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of complex modification methods, environmental pollution, and high production costs, achieve excellent capacity retention rate, and reduce environmental pollution. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

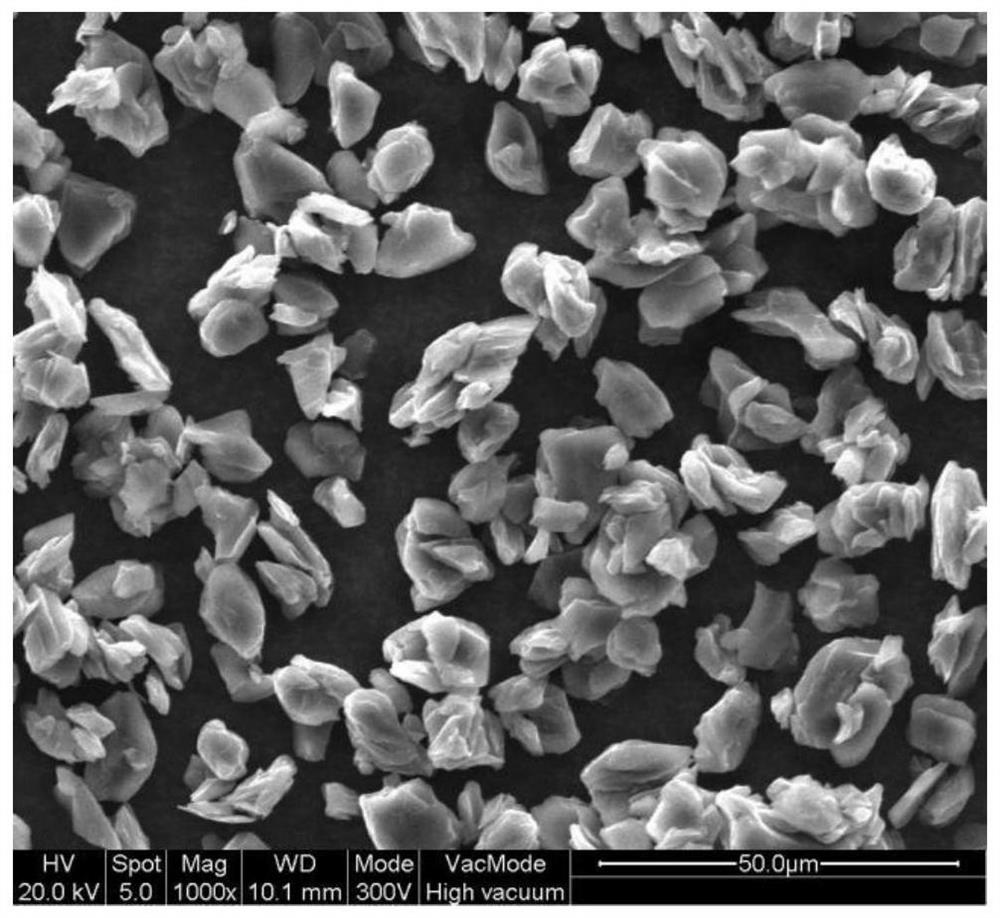

Image

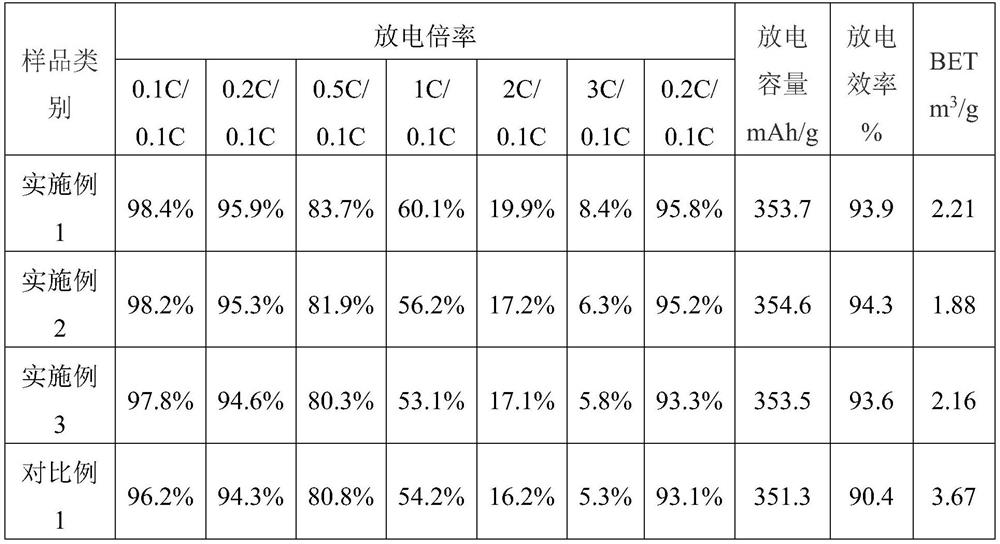

Examples

Embodiment 1

[0023] Preparation of Embodiment 1 Liquid Phase Coated Graphite Negative Electrode Material

[0024] (1) Mechanically pulverize 1200kg of raw coke with a pulverizer, and then shape it with a mechanical grinding and shaping machine to obtain raw coke with a particle size of 8-10μm. Randomly take 200kg of it and place it in a drum furnace at a temperature of 650°C and a pressure of 0.09MPa, thermal stirring treatment under nitrogen protection for 480min; the green coke after thermal stirring treatment is subjected to graphitization treatment at 3500°C, and the graphitization treatment time is 45h;

[0025] (2) Take 80kg of graphitized return material, and mix it with 4kg liquid phenolic resin (viscosity is 21-24mPa s) in the kneading pot and then carry out static carbonization treatment. The temperature of curing treatment in the carbonization treatment process is 90-95 °C, the time of curing treatment is 1h, the temperature of carbonization treatment is 1150°C, and the time of ...

Embodiment 2

[0026] Preparation of Example 2 Liquid Phase Coated Graphite Negative Electrode Material

[0027] (1) Mechanically pulverize 1200kg of raw coke with a pulverizer, and then shape it with a mechanical grinding and shaping machine to obtain raw coke with a particle size of 8-10μm. Randomly take 200kg of it and place it in a drum furnace at a temperature of 600°C and a pressure of 0.09MPa, thermal stirring treatment under nitrogen protection for 480min; the green coke after thermal stirring treatment is subjected to graphitization treatment at 3500°C, and the graphitization treatment time is 45h;

[0028] (2) Get 80kg of graphitized return material, and mix it with 2.4kg liquid phenolic resin (viscosity is 21-24mPa s) in the kneading pot, then carry out static carbonization treatment, and the temperature of curing treatment in the carbonization treatment process is 90- 95°C, the time of curing treatment is 1h, the temperature of carbonization treatment is 1150°C, and the time of c...

Embodiment 3

[0029] Preparation of Example 3 Liquid Phase Coated Graphite Negative Electrode Material

[0030] (1) Mechanically pulverize 1200kg of raw coke with a pulverizer, and then shape it with a mechanical grinding and shaping machine to obtain raw coke with a particle size of 8-10μm. Randomly take 200kg of it and place it in a drum furnace at a temperature of 600°C and a pressure of 0.09MPa, thermal stirring treatment under nitrogen protection for 480min; the raw coke after thermal stirring treatment is subjected to graphitization treatment at 3000°C, and the graphitization treatment time is 45h;

[0031] (2) Take 80kg of graphitized return material, and mix it with 4kg liquid phenolic resin (viscosity is 25-28mPa s) in the kneading pot and then carry out static carbonization treatment. The temperature of curing treatment in the carbonization treatment process is 90-95 °C, the time of curing treatment is 1.5h, the temperature of carbonization treatment is 1150°C, and the time of car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com