A lithium ion battery separator with alternating coating structure and preparation method thereof

A lithium-ion battery and coating technology, applied in structural parts, secondary batteries, battery pack parts, etc. It can shorten the production cycle, reduce the internal resistance, and improve the wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

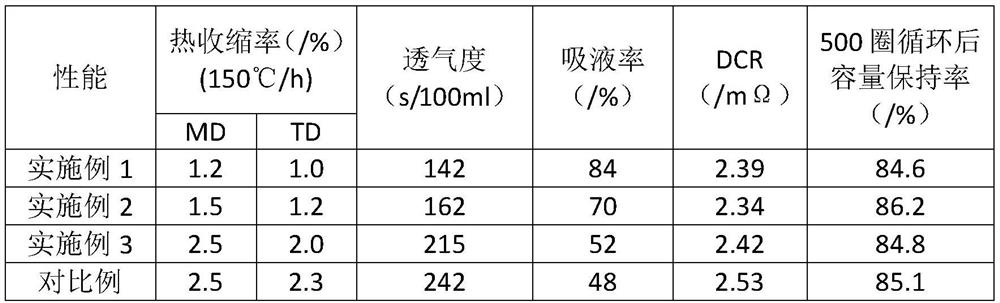

Embodiment 1

[0033] A lithium-ion battery separator with an alternating coating structure was prepared as follows:

[0034] (1) Preparation of ceramic slurry: Mix 62 parts of boehmite, 25 parts of carboxymethyl cellulose, 1 part of ammonium acrylate and 12 parts of polyacrylate, and disperse them in enough deionized water, stir evenly to obtain ceramic slurry material.

[0035] (2) Preparation of PVDF-ceramic mixture slurry: Dissolve 1 part of PVDF polymer into a sufficient amount of NMP to obtain a PVDF polymer solution, and then disperse 99 parts of boehmite into the PVDF polymer solution to obtain a PVDF-ceramic mixture slurry.

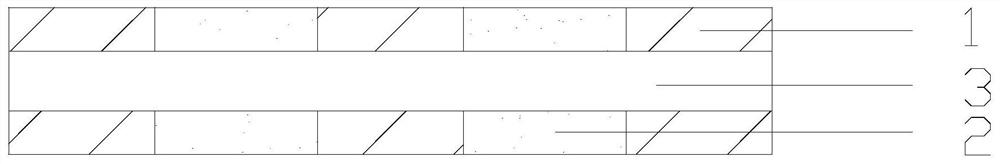

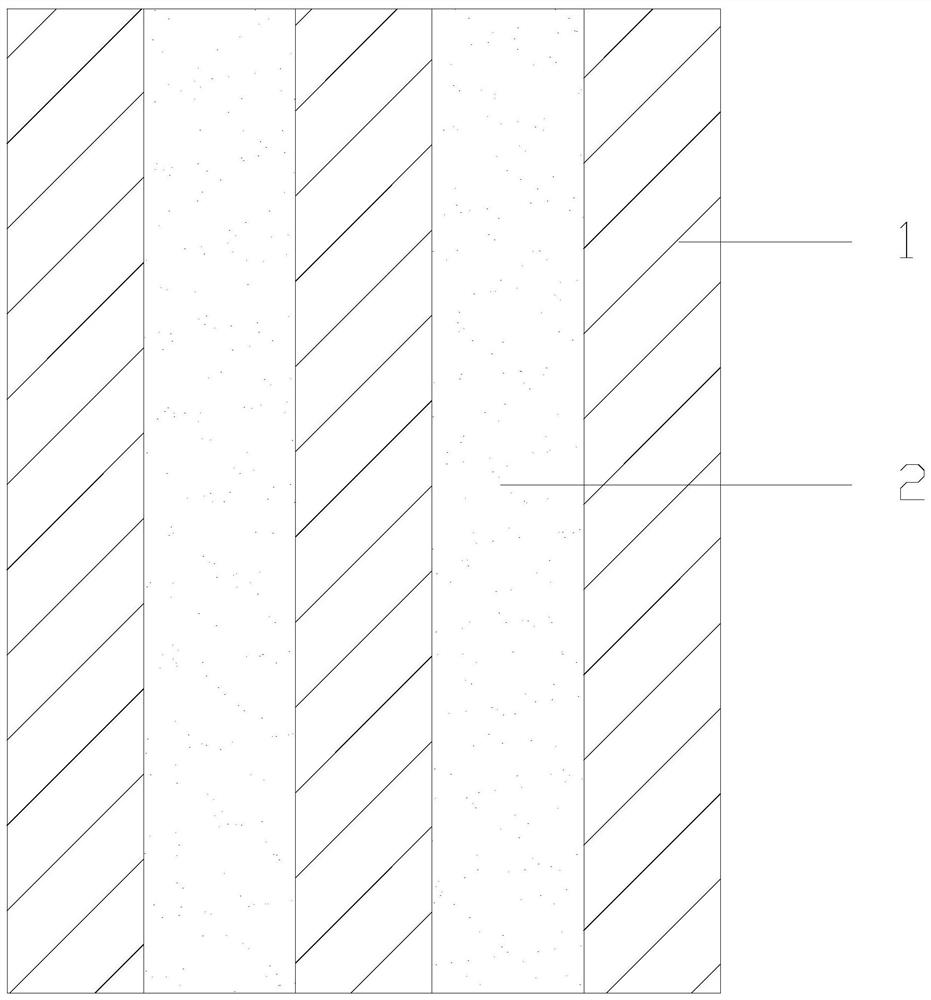

[0036] (3) If figure 1 and figure 2 As shown, the PVDF-ceramic mixture slurry was applied to both sides and the center of both sides of the base membrane, and the ceramic slurry was applied to the remaining area of the base membrane surface with a coating thickness of 3 μm on each side, PVDF-ceramic The widths of the mixture coating and the ceramic coati...

Embodiment 2

[0038] A lithium-ion battery separator with an alternating coating structure was prepared as follows:

[0039] (1) Preparation of ceramic slurry: Mix 62 parts of boehmite, 25 parts of carboxymethyl cellulose, 1 part of ammonium acrylate and 12 parts of polyacrylate, and disperse them in enough deionized water, stir evenly to obtain ceramic slurry material.

[0040] (2) Preparation of PVDF-ceramic mixture slurry: dissolve 25 parts of PVDF polymer into a sufficient amount of NMP to obtain a PVDF polymer solution, and then disperse 75 parts of boehmite into the PVDF polymer solution to obtain a PVDF-ceramic mixture slurry.

[0041] (3) If figure 1 and figure 2 As shown, the PVDF-ceramic mixture slurry was applied to both sides and the center of both sides of the base membrane, and the ceramic slurry was applied to the remaining area of the base membrane surface with a coating thickness of 3 μm on each side, PVDF-ceramic The widths of the mixture coating and the ceramic coa...

Embodiment 3

[0043] A lithium-ion battery separator with an alternating coating structure was prepared as follows:

[0044] (1) Preparation of ceramic slurry: Mix 62 parts of boehmite, 25 parts of carboxymethyl cellulose, 1 part of ammonium acrylate and 12 parts of polyacrylate, and disperse them in enough deionized water, stir evenly to obtain ceramic slurry material.

[0045] (2) Preparation of PVDF-ceramic mixture slurry: dissolve 50 parts of PVDF polymer into a sufficient amount of NMP to obtain a PVDF polymer solution, and then disperse 50 parts of boehmite into the PVDF polymer solution to obtain a PVDF-ceramic mixture slurry.

[0046] (3) If figure 1 and figure 2 As shown, the PVDF-ceramic mixture slurry was applied to both sides and the center of both sides of the base membrane, and the ceramic slurry was applied to the remaining area of the base membrane surface with a coating thickness of 3 μm on each side, PVDF-ceramic The widths of the mixture coating and the ceramic coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com