Lipase-based feed additive, preparation method and application thereof, and broiler feed

A feed additive and broiler feed technology, which is applied in the field of feed additives, can solve the problems of inability to fully decompose high-energy fats, incomplete digestion of oil and fat components, and unsound development of digestive organs, so as to reduce the phenomenon of watery stools and reduce erosion. , the effect of improving growth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

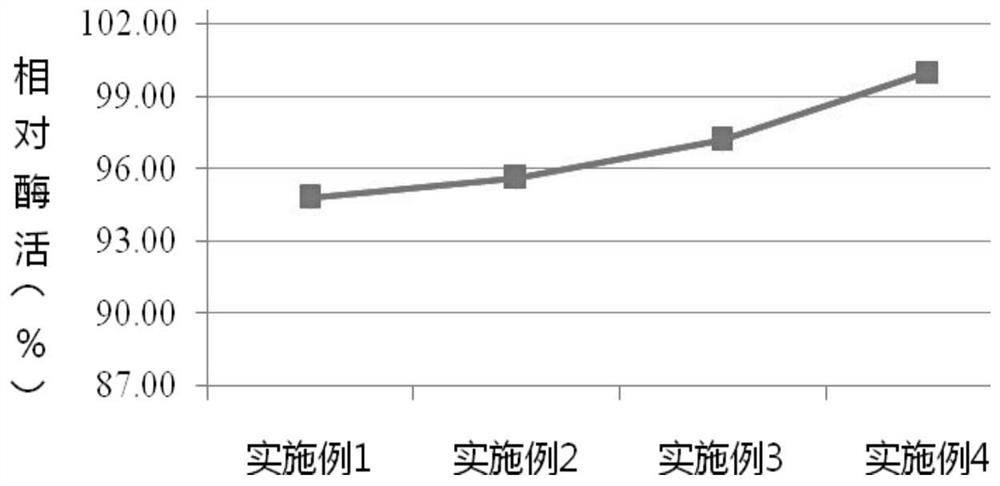

[0024] Example 1:

[0025] This embodiment provides a feed additive based on lipase, which comprises: a composite emulsifier 0.05%; lipase 0.15%; wheat bran is 98%, and the lipase is obtained by black maushan. The enzyme activity of lipase is satisfied with the following conditions: 20000u / g ≤ lipase enzyme activity ≤40000U / g.

[0026] Among them, the composite emulsifier comprises: 80% of lysated lecithin, 15% sucrose ester, 5% bile acid.

[0027] At the same time, the present embodiment also provides a method of preparing the above feed additive comprising the steps of:

[0028] S1, according to the corresponding proportion of composite emulsifiers;

[0029] S2, weigh the composite emulsifier, lipase and carrier of the above ratio, first compound the composite emulsifier to the carrier, stirred for about 5-8 min, mix well, then add the fat enzyme 3 times to the compound emulsified composite emulsification In the agent; preferred, each time the addition of one-third of the fa...

Example Embodiment

[0031] Example 2:

[0032] This embodiment provides a feed additive based on lipase, which comprises: a composite emulsifier 0.18%; lipase 0.02%; rice bran, 99.67%; and by weight, the composite emulsifier comprises: Lysmaloblastin 90%, sucrose ester 5%, mono glycidyl 5%.

[0033] Other technical features are the same as in Example 1, and details are not described herein again.

Example Embodiment

[0034] Example 3:

[0035] This embodiment provides a feed additive based on lipase, which comprises: a composite emulsifier 0.15%; lipase 0.10%; starch 99.75%; and by weight, the composite emulsifier comprises: Lysmaloblastin 80%, sucrose ester 10%, monoglyceride 10%.

[0036] Other technical features are the same as in Example 1, and details are not described herein again.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap