Conveying device for low-temperature candy packaging

A conveying device and candy technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of candy temperature rise, difficult to clean the device, and low conveying efficiency, so as to avoid sticking together and facilitate packaging The effect of using and ensuring hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example 1

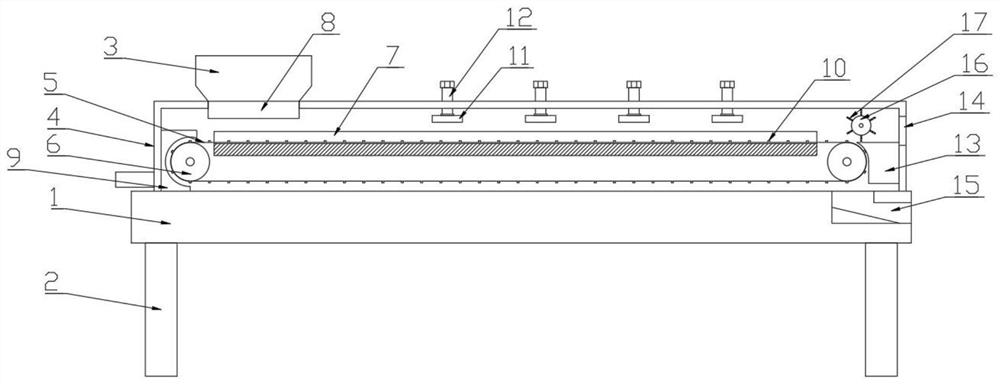

[0020] Please refer to the figure, in the embodiment of the present invention, a transport device of a low temperature candy package includes a delivery support platform 1, a leg 2, a feed strip 3, a conveying tank 4, a conveyor belt 5, and a transmission wheel 6; the transport support The platform 1 is arranged, and a plurality of legs 2 are fixed to the bottom of the conveying support platform 1, the support delivery support platform 1, and the transport case 4 is fixed to the conveying support platform 1, and in the left end of the conveying box 4 The hopper 3, which will be supplied from the leg 2 into the conveying case 4; in the conveying box 4 mounted a horizontal conveyor belt 5, both ends of the conveyor belt 5 are bypass from the two drive wheels 6, respectively. The drive motor 6 is connected to the drive motor, so that the drive wheel 6 is rotated, the conveyor belt 5 is driven, and the left end of the conveyor belt 5 is below the feed hopper 3, and ...

Example Embodiment

[0025] Example 2

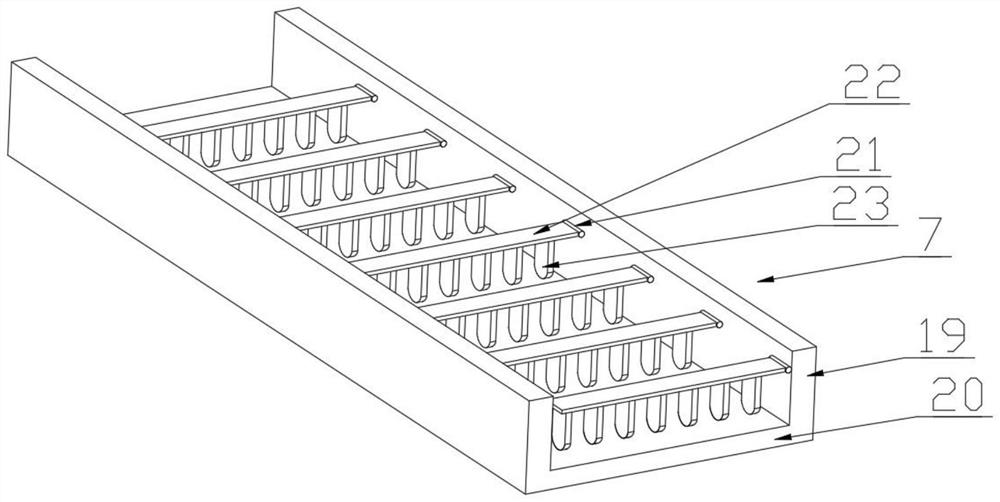

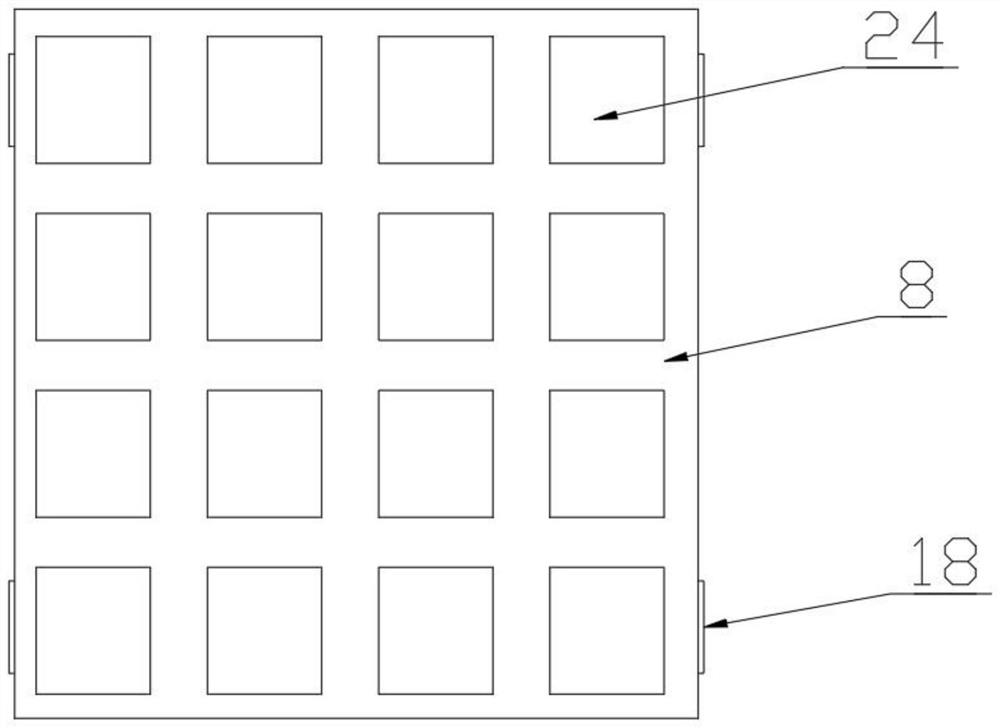

[0026]On the basis of Example 1, the lower material block 8 is attached to the bottom of the feed hopper 3, and several lower blade ports 24 are opened on the lower material block 8, and the blanket 24 is arranged in a matrix. The falling candy is discharged, and the block 18 is provided on the outer side of the lower material block 8, and the card block 18 is replaced by the card block 18, and the support conduit groove 7 side side A plurality of rotating shafts 21 are mounted on the baffle 19, and the swing plate 22 is provided on each of the rotating shafts 21, and the swing plate 22 is rotated across the support bottom plate 20, and the swing plate 22 can rotate around the shaft 21 in the vertical direction. Adjust the inclination angle, the lower surface of the swing plate 22 is fixedly mounted having a row of separation plates 23 that distribute one by one by one by one by one by one by one by one by one by one, the lower end of the separation plate 23 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap