Deslagging mechanism special for acetylene recovery in dry acetylene carbide slag

A dry-process acetylene and calcium carbide slag technology, applied in filtration circuits, organic chemistry, separation methods, etc., can solve the problems of high consumption of calcium carbide and large difference in the hydrolysis rate of calcium carbide, achieve small water consumption, reduce dust content, and improve secondary The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

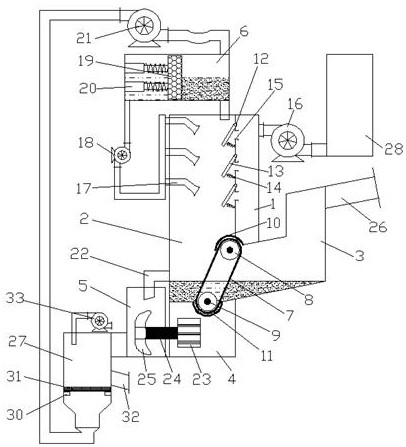

[0025] refer to figure 1 , a slag discharge mechanism dedicated to the recovery of acetylene from dry-process acetylene carbide slag, including an air intake chamber 1, a spray chamber 2, an exhaust chamber 3, a motor chamber 4, a slurry mixing tank 5, a filter press cylinder 27 and a slurry separation Tank 6, the exhaust chamber 3 is an L-shaped cavity structure, the exhaust chamber 3 communicates with the lower part of the side wall of the spray chamber 2, and the exhaust chamber 3 communicates with the spray chamber 2 A filter screen 7 is arranged at the center, and the filter screen 7 is specifically a circle of mesh cloth composite structure formed by winding tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com