Fan heat dissipation combination device

A combined device and fan technology, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices for elastic fluids, and can solve problems such as inability to be cleaned automatically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

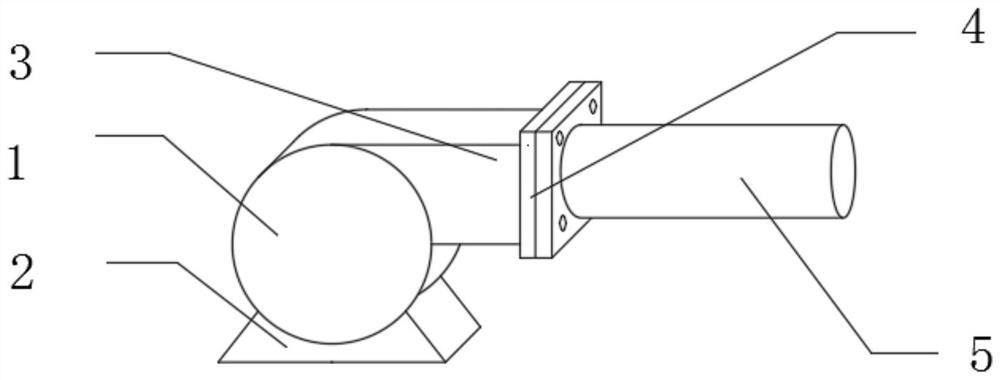

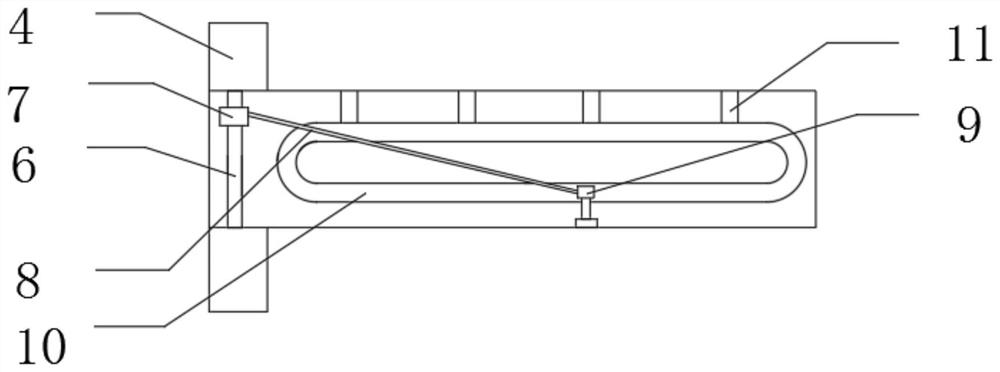

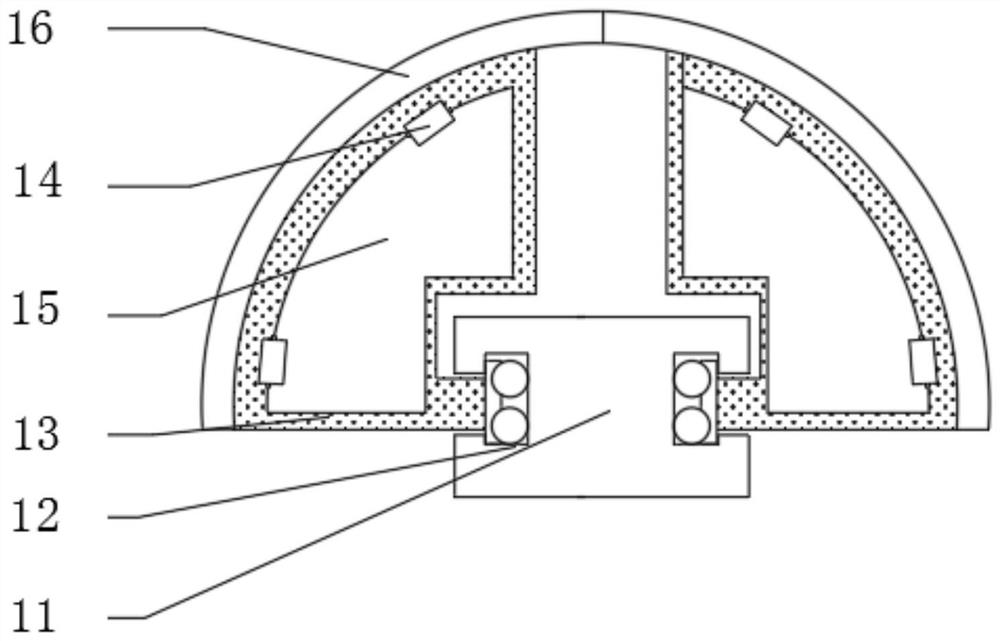

[0024] see Figure 1-3 , in this embodiment: a fan cooling combination device, including a fan main body 1, the lower end of the fan main body 1 is connected to a base 2, the upper end of the fan main body 1 is connected to an air outlet pipe 3, and one end of the air outlet pipe 3 is connected to the connection port 4 One end of the connecting port 4 is connected with an exhaust pipe 5, the inner side of the connecting port 4 is provided with a first fixed rod 6, the inner side of the first fixed rod 6 is connected with a fixed block 7, and one end of the fixed block 7 is connected with a spring rope 8, One end of spring rope 8 is connected with trolley 9, and the inboard of trolley 9 is connected with slide rail 10, and the upper end of slide rail 10 is connected with second fixed rod 11, and the inboard of slide rail 10 is provided with chute 12, and the inboard of trolley 9 The outer surface is connected with a fixed frame 13, the inner side of the one-way hinge 14 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com