Nuclear power station storage battery test direct current load device

A technology of DC load and battery, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problems of insufficiency, large inrush current and programmability, and achieve the effect of convenient size, shortened construction period and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] In order to make the 1E-class batteries of AP / CAP series nuclear power plants meet the battery load curve and the first-minute impact load requirements under the two working conditions of power failure and LOCA, and the installation space of 1E-class batteries is relatively narrow. Programming modular design ideas to design and manufacture DC load boxes.

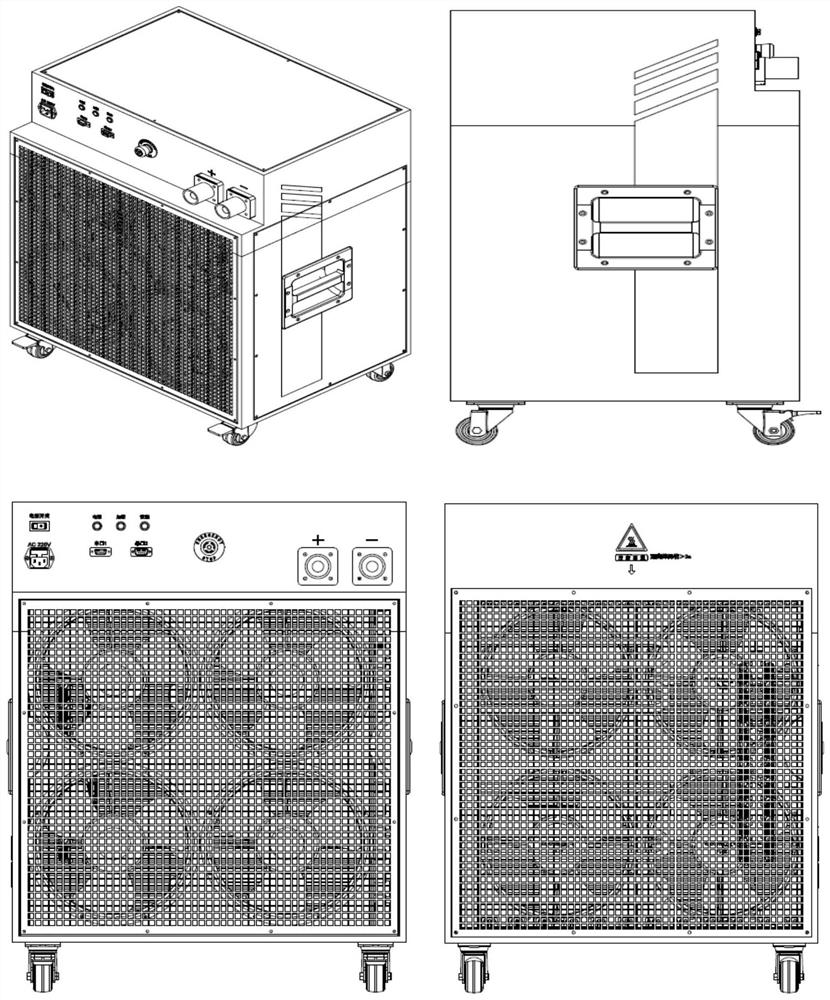

[0029] 1. Appearance of programmable modular DC load box, such as figure 1 shown.

[0030] 2. The appearance of the combiner box, such as figure 2 shown.

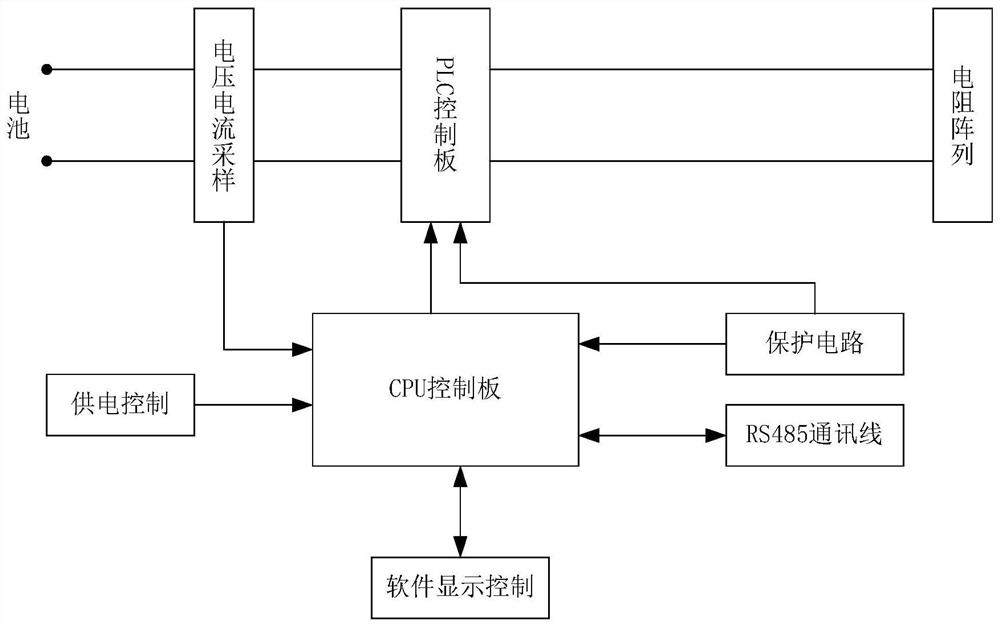

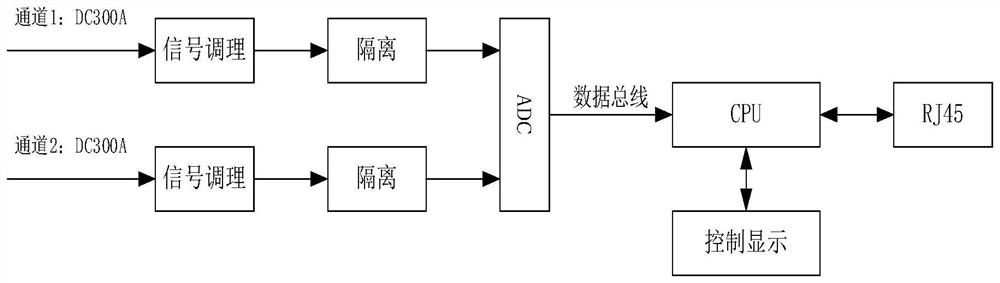

[0031] 3. The programmable modular DC load box is mainly composed of electrical signal acquisition circuit, PLC control board, resistor array, CPU control board, protection circuit, remote communication circuit, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com