Food fermentation process

A food fermentation and process technology, applied in the direction of tea treatment before extraction, can solve the problems of affecting the effect of tea kneading, poor tea quality and difficult to clean, affecting the fermentation effect, etc., to achieve convenience, improve vibration stability, improve The effect of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

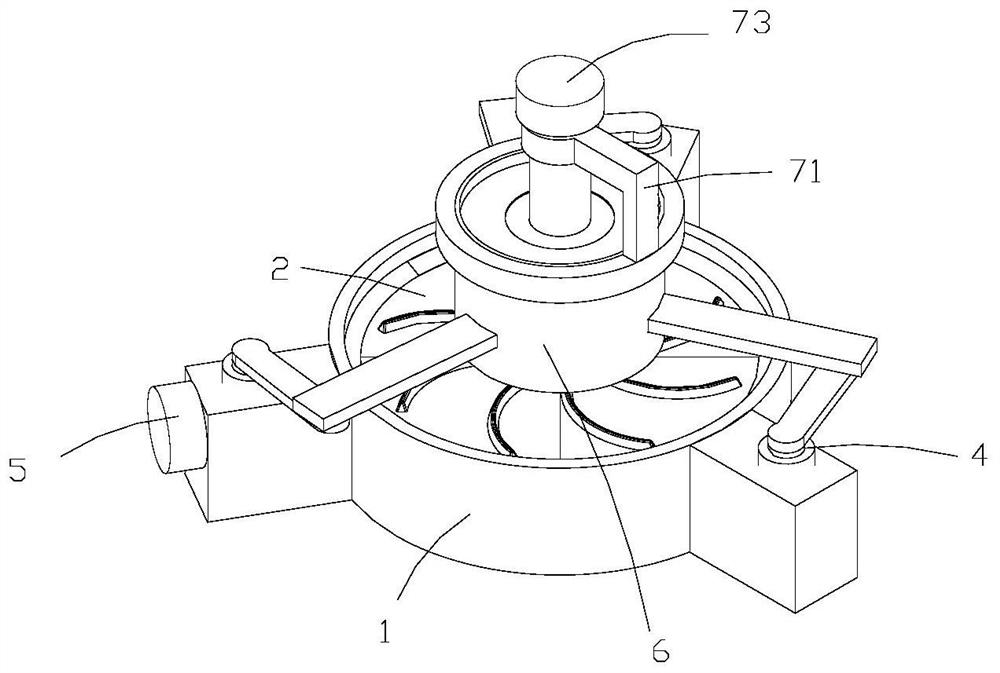

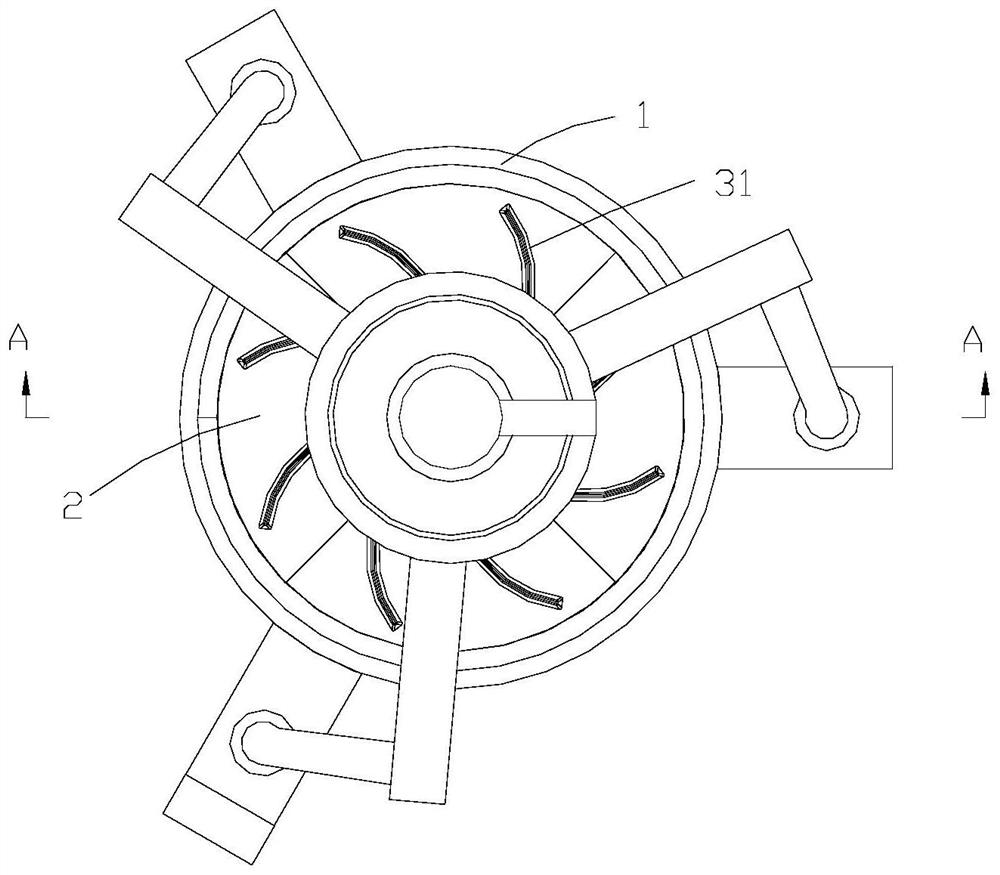

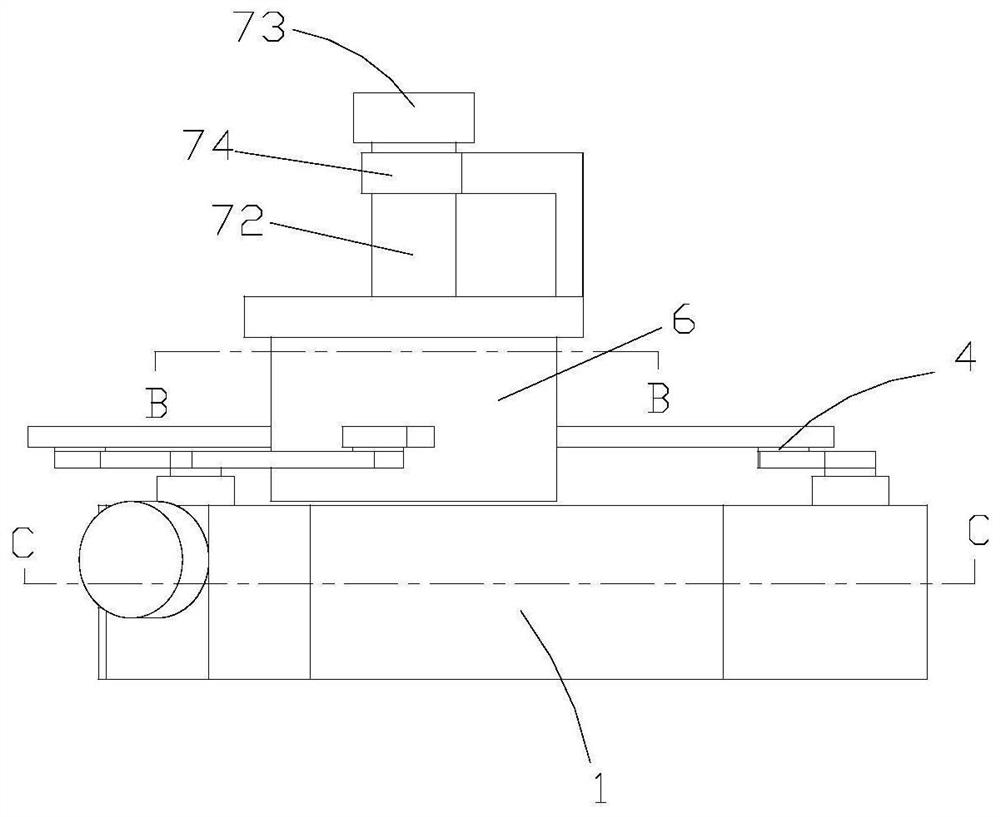

[0037] Such as Figure 1-12 Shown, a kind of food fermentation process comprises the following steps:

[0038] a. Pretreatment: tile the fresh tea leaves, put them into Aspergillus oryzae, and then irradiate them with infrared light for 2 hours;

[0039] b. Kneading: Add 2 parts of starch by weight to the tea leaves, rub and knead the tea leaves for 0.2 hours, then add 2 parts of starch by weight to the tea leaves, and continue to knead for 0.6 hours; knead the tea leaves every Knead for 3 minutes, stop for 1.5 minutes;

[0040] c. Steaming: the tea leaves after kneading are steamed with steam at 100°C for 8 minutes;

[0041] d. Fermentation: Add 8 parts of lactic acid bacteria, 4 parts of acetic acid bacteria, and 10 parts of yeast to the steamed tea leaves respectively; then place the tea leaves in an environment of 240MPa, control the temperature of the tea leaves at 29°C, and keep for 0.6h; Finally, put the tea leaves in a fermentation room with a temperature of 25°C an...

Embodiment 2

[0049] A food fermentation process, comprising the following steps:

[0050] a. Pretreatment: tile the fresh tea leaves, put them into Aspergillus oryzae, and then irradiate them with infrared light for 3 hours;

[0051] b. Kneading: add 3 parts of starch by weight to the tea leaves, rub and knead the tea leaves for 0.3 hours, then add 3 parts of starch by weight of tea leaves, and continue to knead for 0.9 hours; knead the tea leaves every Knead for 5 minutes, stop for 2 minutes;

[0052] c. Steaming: steam the tea leaves after kneading with steam at 108°C for 10 minutes;

[0053] d. Fermentation: Add 8-10 parts of lactic acid bacteria, 4-6 parts of acetic acid bacteria, and 10-15 parts of yeast to the steamed tea leaves; then place the tea leaves in an environment of 240-300 MPa to control the temperature of the tea leaves Keep at 29-32°C for 0.6-1h; finally put the tea leaves in a fermentation room with a temperature of 25-28°C and a relative humidity of 92-96°C to fermen...

Embodiment 3

[0055] A food fermentation process, comprising the following steps:

[0056] a. Pretreatment: flatten the fresh tea leaves, put them into Aspergillus oryzae, and then irradiate them with infrared light for 2.5 hours;

[0057] b. Kneading: add 2.5 parts of starch by weight to the tea leaves, rub and knead the tea leaves for 0.25 hours, then add 2.5 parts of starch by weight to the tea leaves, and continue to knead for 0.7 hours; knead the tea leaves every Knead for 4 minutes and stop for 1.7 minutes;

[0058]c. Steaming: the tea leaves after kneading are steamed with steam at 1.4°C for 9 minutes;

[0059] d. Fermentation: Add 9 parts of lactic acid bacteria, 5 parts of acetic acid bacteria and 12 parts of yeast to the steamed tea leaves respectively; then place the tea leaves in an environment of 270MPa, control the temperature of the tea leaves at 30°C and keep for 0.8h; Finally, put the tea leaves in a fermentation room with a temperature of 27° C. and a relative humidity o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap