Flexible pneumatic tensioning clamp for inner hole of slender hard and brittle thin-wall pipe fitting and working method

A technology for tensioning fixtures and thin-walled pipes, which is applied in the direction of manufacturing tools, grinding drive devices, metal processing equipment, etc., can solve the problems of slender pipes, thin-walled structural materials, hard and brittle, and brittle fractures, so as to relieve stress Concentrate, improve support rigidity, and prevent embrittlement damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in combination with technical solutions and accompanying drawings.

[0019] The outer circular surface of the pipe fittings made of ceramic matrix composites is processed. The total length of the pipe fittings is 1000-2000mm, the outer diameter is 12mm, and the inner diameter is 10mm.

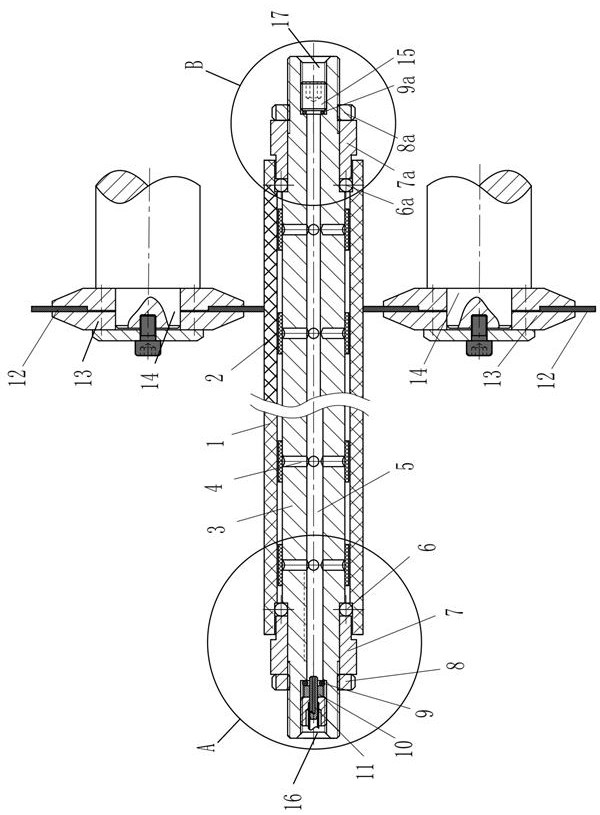

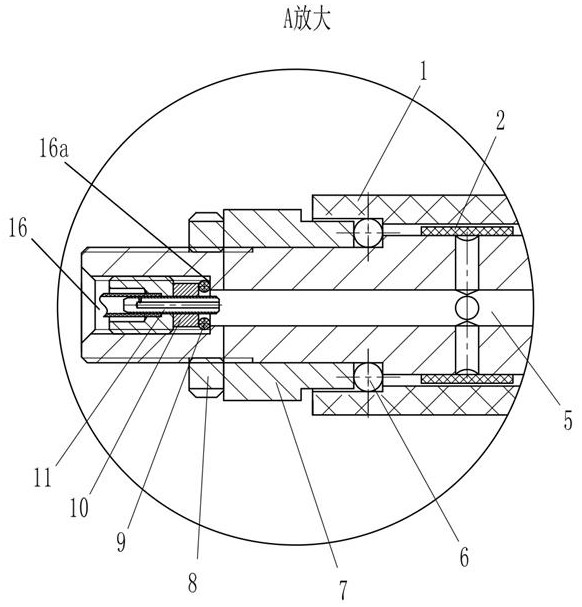

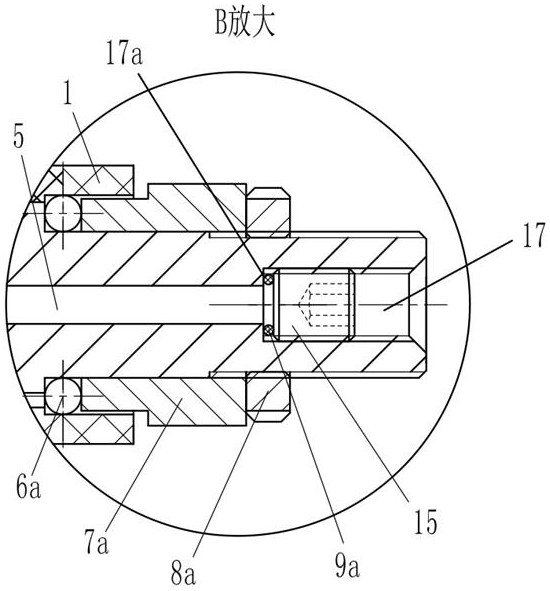

[0020] figure 1 , 2 , 3 shows a structural diagram of a flexible pneumatic tensioning fixture for the inner hole of a slender, hard, brittle, and thin-walled pipe. This flexible pneumatic tensioning fixture clamps the pipe fitting 1 and adopts two symmetrically arranged thin-walled grinding wheels 12 to synchronously grind the outer circular surface of the pipe fitting 1 in a manner similar to point grinding. The flexible pneumatic tensioning fixture is a kind of flexible pneumatic tensioning fixture that is in intermittent contact with the inner hole of the pipe fitting 1. On the hollow mandrel 3 whose diameter is smaller than th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com