Preparation method of diethyl germanium dihalide

A technology of diethyl germanium dihalide and diethyl germanium dichloride, which is applied in the direction of germanium organic compounds, etc., can solve the problems of not conforming to the concept of green environmental protection, troublesome use and transportation, and complicated tail gas treatment, so as to avoid toxic gases Effects of leakage, less product impurities, and reduction of process burden and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

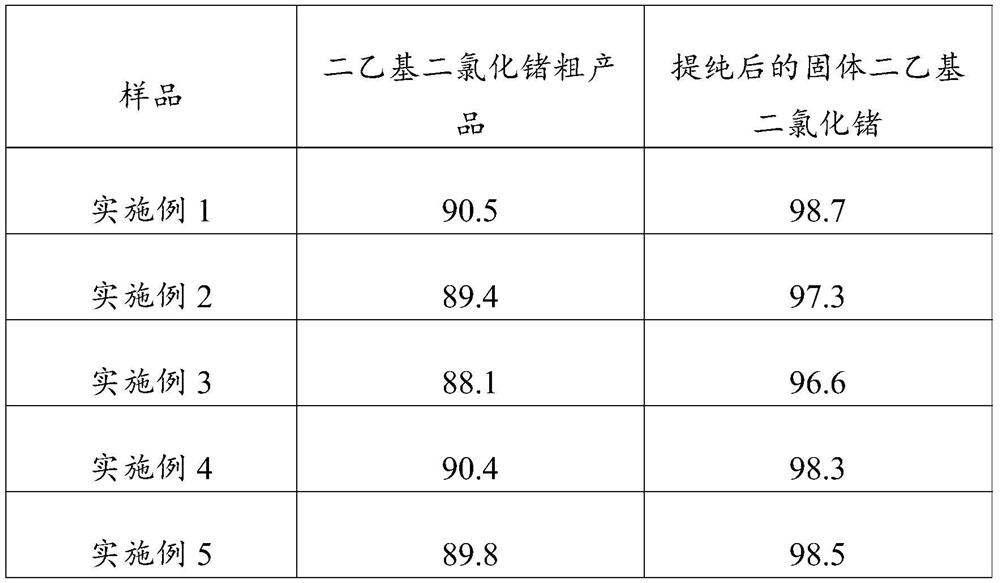

Embodiment 1

[0034] A kind of preparation method of diethylgermanium dichloride as the embodiment of the present invention, described method comprises the following steps:

[0035] (1) Mix ethylmagnesium iodide and germanium tetrachloride in organic solvent A under acidic conditions and react at a temperature not exceeding 10°C to obtain tetraethylgermanium; purify tetraethylgermanium to obtain purified tetraethylgermanium Ethyl germanium; the preparation method of the diethyl germanium dihalide also includes the preparation step of ethyl magnesium iodide, and the preparation step of the ethyl magnesium iodide comprises: under the protective gas atmosphere, magnesium is placed in an organic solvent Reaction system A is obtained in B, heated to 40-60°C, dropwise adding iodoethane solution to the reaction system A under stirring, controlling the reaction temperature to be 40-60°C, stirring reaction 1 after the iodine solution is added dropwise ~2h, the solvent of ethyl iodide solution is org...

Embodiment 2

[0042] As a preparation method of diethylgermanium dichloride in the embodiment of the present invention, the only difference between this embodiment and Example 1 is: under the protection of nitrogen, the tetraethylgermanium in step (II) and 96.3 g of tetraethylgermanium The germanium chloride was mixed evenly in the high-temperature autoclave, and the high-temperature autoclave was transferred to the high-temperature roller heating furnace, and the rolling was started, and the temperature was set at 300°C for 31 hours of reaction.

Embodiment 3

[0044] As a preparation method of diethylgermanium dichloride in the embodiment of the present invention, the only difference between this embodiment and Example 1 is: under the protection of nitrogen, the tetraethylgermanium in step (II) and 96.3 g of tetraethylgermanium The germanium chloride was mixed evenly in the high-temperature autoclave, and the high-temperature autoclave was transferred to the high-temperature roller heating furnace, and the rolling was started, and the temperature was set at 400°C for 31 hours of reaction.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap