Aluminum oxide feeding and concentration controlling method for aluminum electrolysis cell

A technology of aluminum electrolytic cell and control method, which is applied in the field of aluminum electrolysis, can solve problems such as constant control of alumina concentration and pole distance, drift of alumina concentration, and increase of anode effect in super-large aluminum electrolytic cells, so as to prevent concentration drift, Reduce thermal shock and achieve precise control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] Example 1

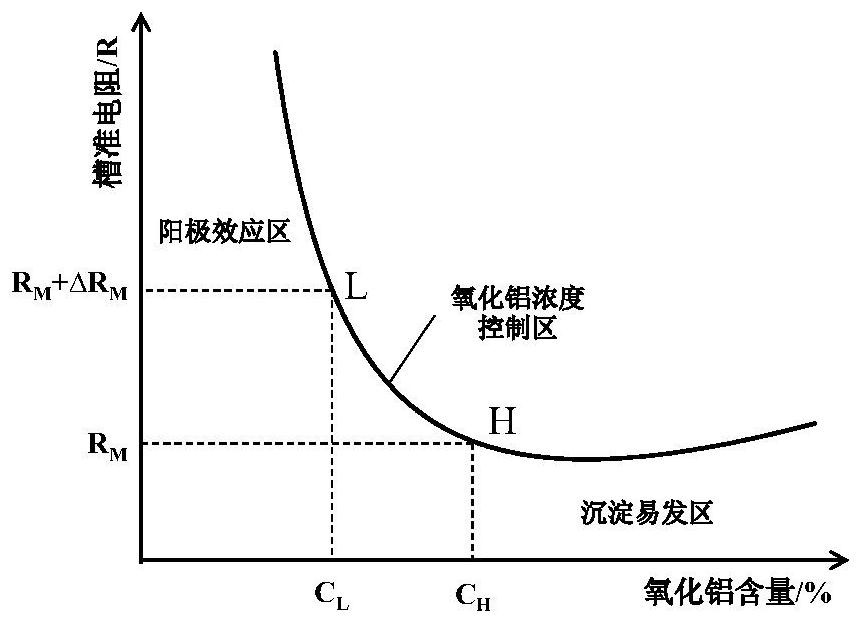

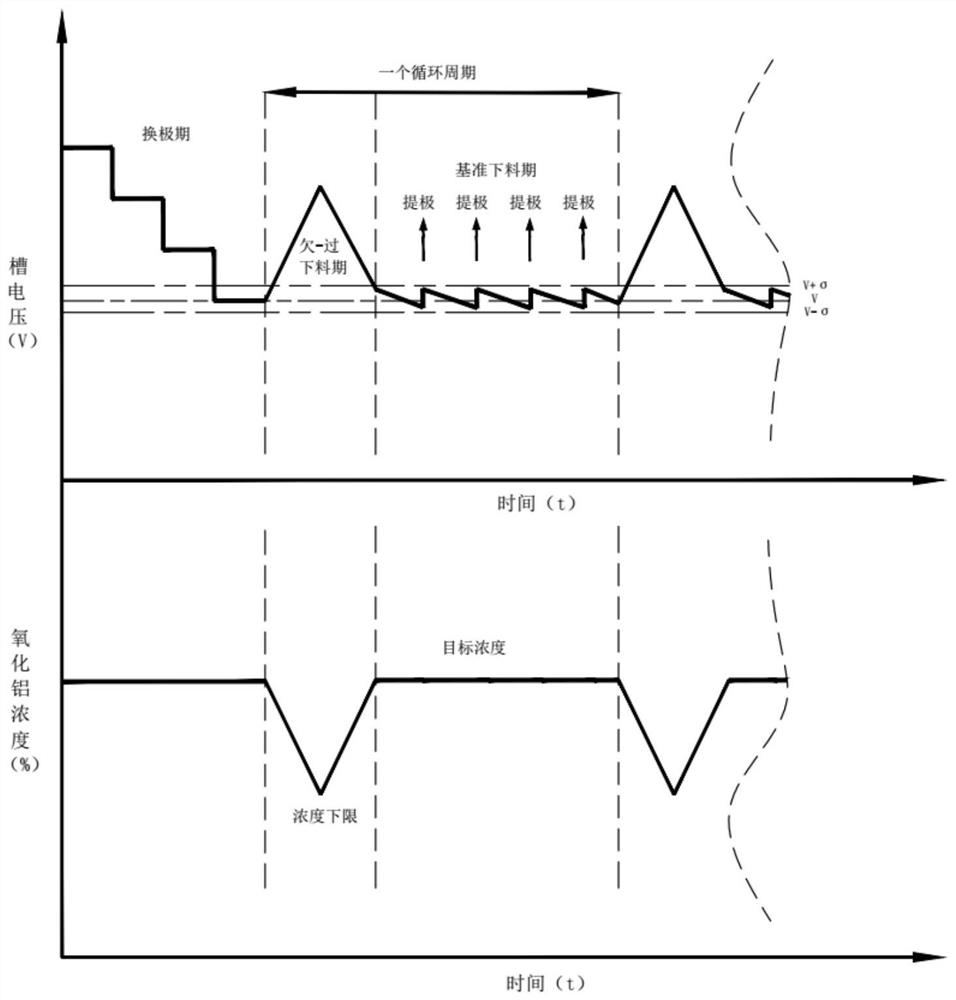

[0043] like figure 2 As shown in the figure, an aluminum electrolytic cell alumina blanking and concentration control method of the present invention includes a pole change period, and then enters an under-over blanking period after the pole change period ends, and the under-over blanking period includes an under-volume period and an excess The under-over-feeding period is a half-cycle, first the under-feed period and then the over-feed period. After the lower limit of the alumina concentration is determined during the under-over-feed period, the concentration in the tank reaches the target concentration and then enters the benchmark feeding period. At the beginning of the blanking period, the initial blanking rate is given, and the resistance pole distance is compensated for multiple times during the benchmark blanking period, and the blanking rate is adjusted in real time between the two pole distance compensations.

[0044] The alumina concentration in ...

Example Embodiment

[0054] Example 2

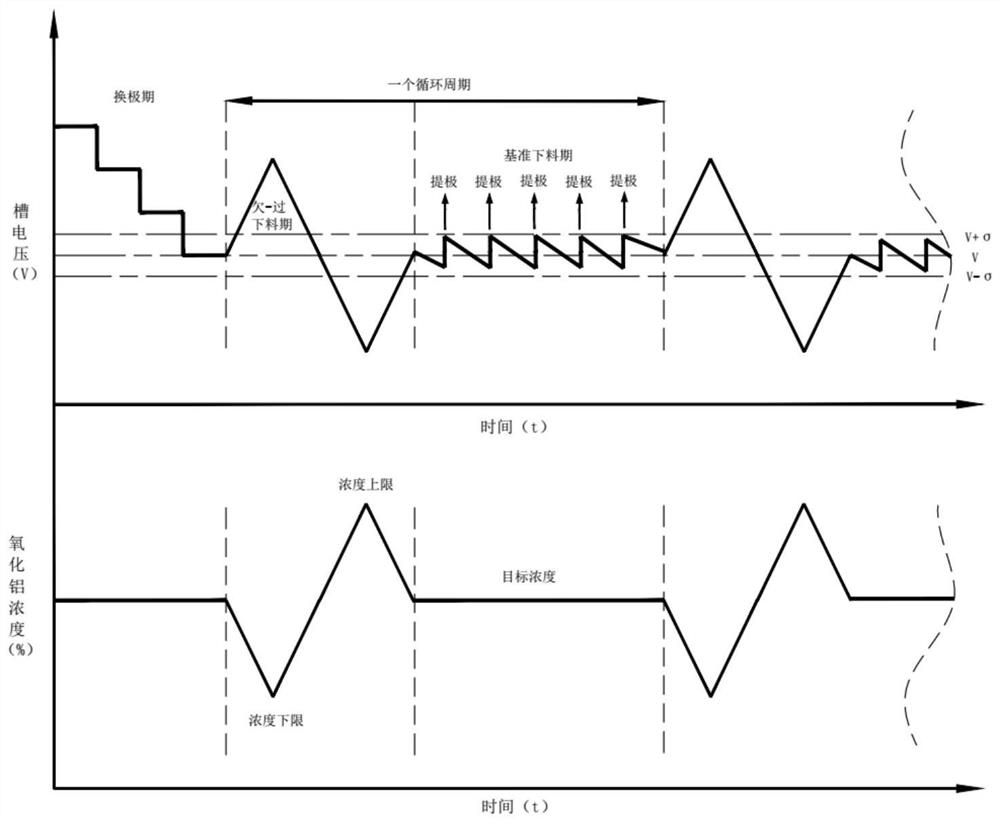

[0055] like image 3 As shown, an aluminum electrolytic cell alumina blanking and concentration control method, including a pole change period, after the end of the pole change period, enter the under-over blanking period, the under-over blanking period includes the under-quantity period and the excess period, The under-over-feeding period is the full cycle. The under-supply period is followed by the over-supply period. After determining the lower limit of the alumina concentration in the under-volume period, the upper limit of the alumina concentration is determined after an over-supply period, and the concentration is double calibrated. After a period of The time is insufficient to discharge the material, so that the concentration in the tank reaches the target concentration and then enters the benchmark blanking period. The initial blanking rate is given at the beginning of the benchmark blanking period, and the resistance pole distance is compensated for...

Example Embodiment

[0064] Example 3

[0065] like Figure 4 As shown, the under-over-feeding period in Example 1 is a half cycle, the upper limit of the alumina concentration is 2.7%, the lower limit of the alumina concentration is 1.8%, a cycle period is 6 hours, and the real-time adjustment of the reference feeding rate When the cell voltage is constant, the reference blanking rate is adjusted in real time according to the cell voltage change rate dV / dt: when (dV / dt)×Δt>σ, adjust NB to be NB-ΔNB; when (dV / dt)×Δt When <-σ, adjust NB to be NB+ΔNB, where Δt is the calculation time step taken, σ is the allowable voltage error, NB reference blanking time interval, and ΔNB fine-tuning amount for each time interval.

[0066] Take a 500kA electrolytic cell as an example to describe the real-time adjustment of the reference blanking rate in detail:

[0067] For example, the calculated time step Δt is 20 seconds, the allowable voltage error σ is 12 mV, the reference blanking time interval NB is 70.2 s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap