Online catalytic slurry oil filter tank

A technology for catalyzing oil slurry and filter box, which is applied in filtration and separation, refining by filtration method, and fixed filter element filter, etc., can solve the problems of low utilization value, air pollution of oil fume, and easy damage to the filter screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

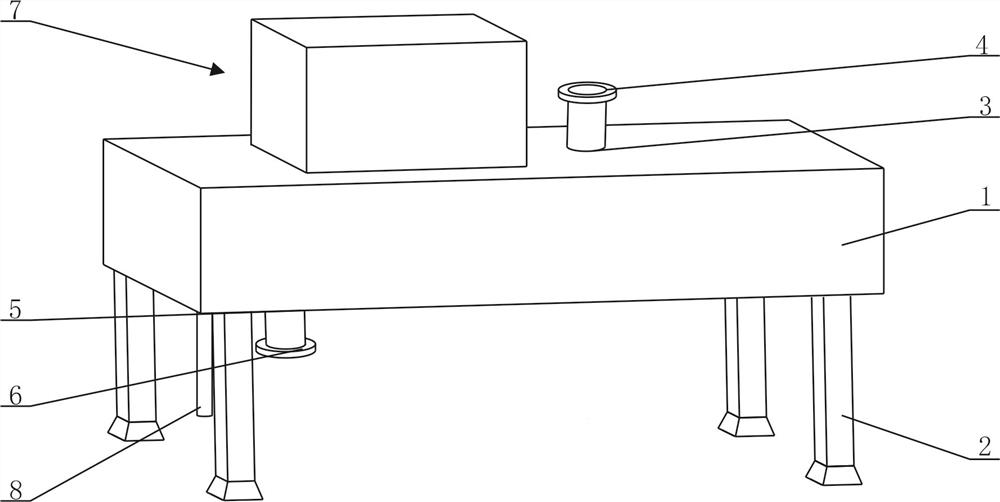

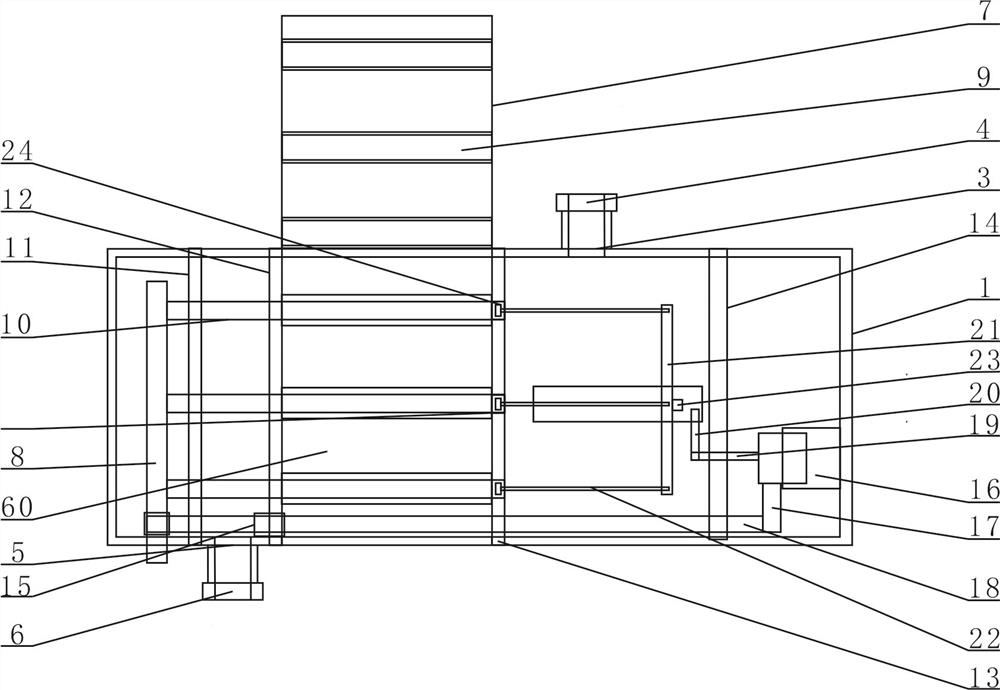

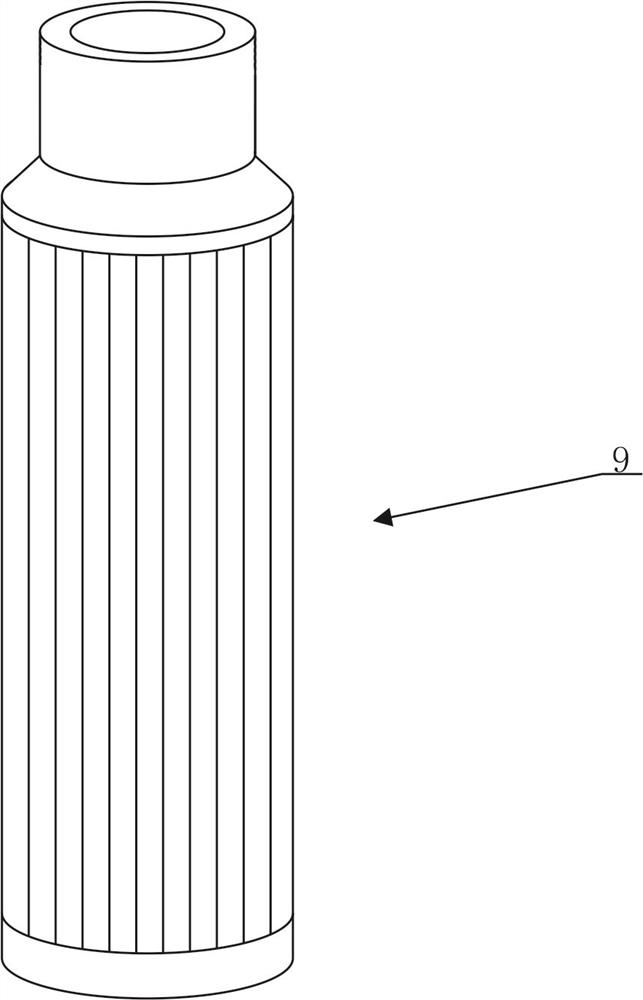

[0045] Embodiment 1, in conjunction with attached Figure 1~15 As shown, the catalytic oil slurry on-line filter box of the present invention, when in use, the catalytic oil slurry on-line filter box is installed on the pipeline for transporting the catalytic oil slurry, and the oil inlet connection plate 4 of the catalytic oil slurry on-line filter box is connected to the inlet The oil pipeline and the oil outlet connection disc 6 of the catalytic oil slurry online filter box are connected to the oil outlet pipeline. There is a filter chamber 60 inside the catalytic oil slurry online filter box. There is a filter element 9 inside the filter chamber 60. There is a decontamination device 26 on the surface of the filter element 9. The bottom of the filter element 9 is provided with a sewage discharge device 64. When the sewage discharge device 64 is opened to discharge sewage, the external pressure of the filter element is greater than the internal pressure of the filter element,...

Embodiment 2

[0046] Embodiment 2, in conjunction with attached Figure 1~12 As shown, the decontamination device 26 is composed of a scraping device 27, a first connecting rod 21, a third connecting rod 23 and a transmission device 28. The first connecting rod 21 is arranged on the scraping device 27, and the first connecting rod 21 is provided with There is a third connecting rod 23, the third connecting rod 23 is provided with a transmission device 28, the transmission device 28 is connected with the motor unit 16, and the scraping device 27 is composed of a scraper 24 and a second connecting rod 22, and the scraper 24 is provided with There is a second connecting rod 22, the second connecting rod 22 is connected with the first connecting rod 21, the motor unit 16 forwardly drives the third transmission rod 19 to rotate, the rotation of the third transmission rod 19 drives the rotation of the fourth transmission rod 20, and the fourth transmission rod 20 rotates. The rotation of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com