Method for smelting oxide ore

A smelting method and oxide technology, which is applied in the field of dry smelting of oxide ores, can solve the problems of difficulty in stacking lumps, increased cost, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

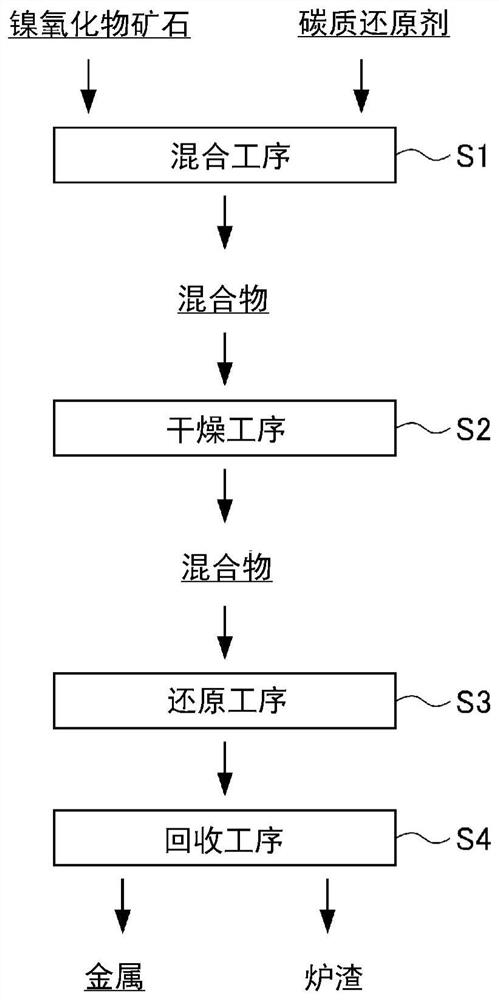

[0057] figure 1 It is a process chart showing the process flow of the nickel oxide ore smelting method. Such as figure 1 As shown, the method for smelting nickel oxide ore in this embodiment (first embodiment) includes: a mixing step S1 of mixing raw materials of nickel-containing oxide ore; a drying step S2 of drying the obtained mixture; A reduction step S3 in which the mixture is heated to a predetermined reduction temperature and then reduced; and a recovery step S4 in which the metal and slag obtained as a reduction product are separated and the metal is recovered.

[0058] [mixing process]

[0059] The mixing step S1 is a step of mixing raw material powders of nickel-containing oxide ore to obtain a mixture. Specifically, in the mixing step S1, nickel oxide ore as a raw material ore is mixed with a carbonaceous reducing agent, and iron ore, a flux component, a binder, etc. Powders with a diameter of about 0.1 mm to 0.8 mm were mixed to obtain a mixture.

[0060] At ...

Embodiment approach

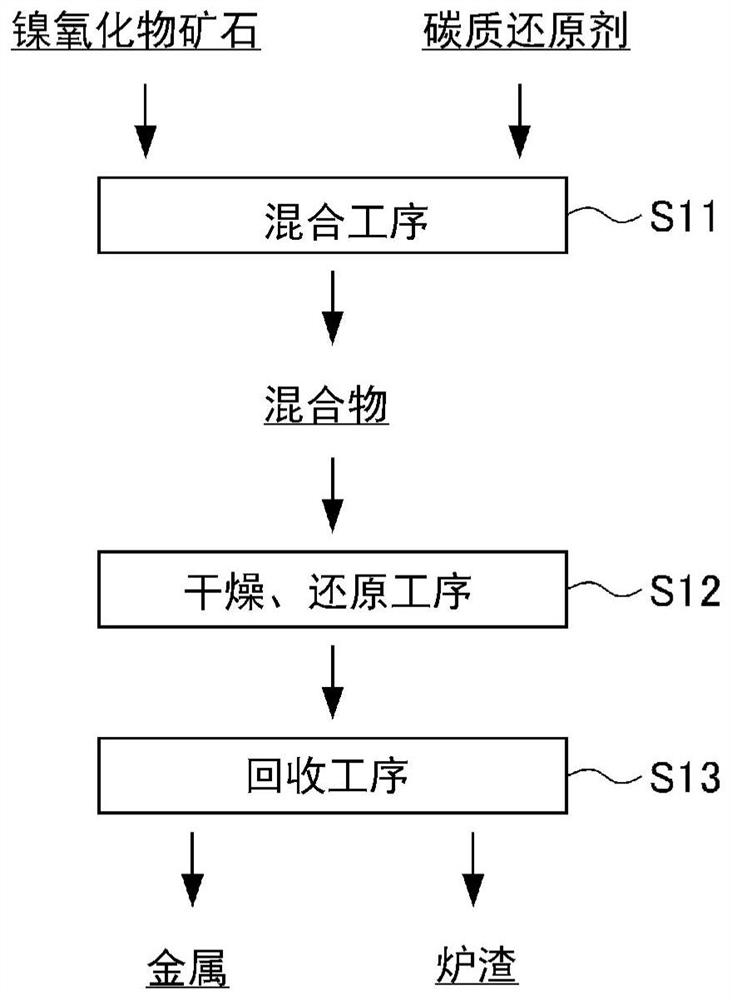

[0105] image 3 It is a process chart showing the flow of the method for smelting nickel oxide ore according to the second embodiment. Such as image 3 As shown, in the smelting method of the second embodiment, unlike the smelting method of the first embodiment, the drying process and the reducing process are performed together.

[0106] Specifically, the method for smelting nickel oxide ore according to the second embodiment includes: mixing process S11, mixing raw materials of nickel oxide ore; drying and reducing process S12, putting the obtained mixture into a reduction furnace for drying treatment and performing a reduction treatment; and a recovery step S13 of separating the obtained metal and slag as a reduction product and recovering the metal.

[0107] It should be noted that since the mixing step S11 and the recovery step S13 respectively correspond to the mixing step S1 and the recovery step S4 in the smelting method of the first embodiment and perform the same pr...

Embodiment 1

[0120] >

[0121] (mixing process)

[0122] Nickel oxide ore and iron ore as raw material ores, silica sand and limestone as flux components, binder and carbonaceous reducing agent (coal powder, carbon content: 82% by mass, average particle size: about 65 μm), The mixture was obtained by mixing using a mixer while adding an appropriate amount of water. It should be noted that, regarding the carbonaceous reducing agent, nickel oxide (NiO) and iron oxide (Fe 2 o 3 ) is contained at a ratio of 27% by mass when the amount required for reduction without excess or deficiency is 100% by mass.

[0123] (drying process, reduction process)

[0124] In Example 1, the obtained mixture was directly loaded into the drying equipment without molding and dried at a temperature above 180° C. for 1 hour, and the dried mixture was charged into a reduction furnace with a burner (combustion furnace )middle. A gas burner using gas fuel is used as the burner. In the combustion furnace, the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com