Porous guniting bidirectional three-dimensional stirring synergistic device and method for solidifying/oxidizing polluted soil

A polluted soil, three-dimensional technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of solidified polluted soil durability degradation, limited range of influence of diffusion, uneven mixing of mixing bodies, etc., to achieve contaminated soil treatment Thoroughness, improvement of heavy metal solidification rate/organic matter removal rate, and guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

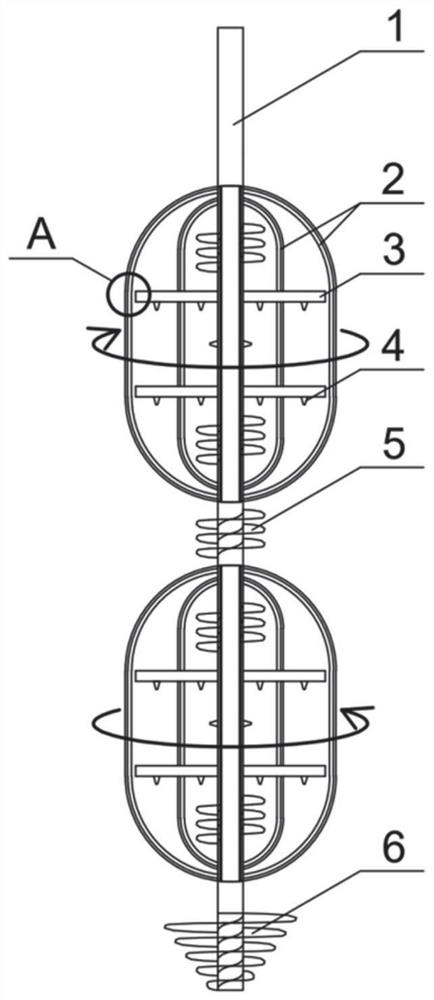

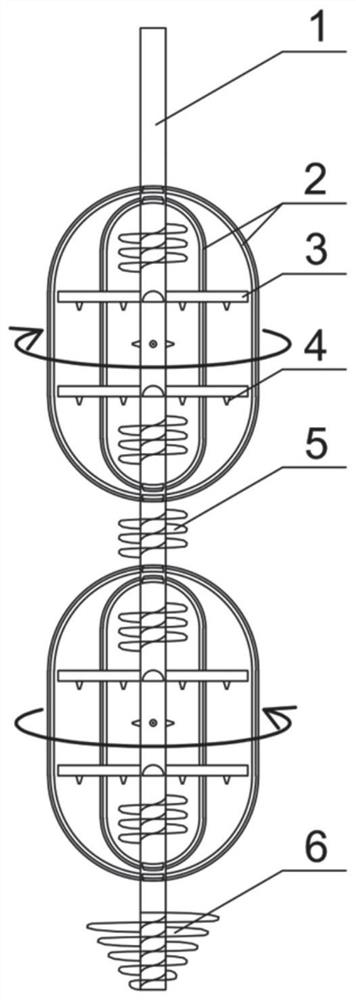

[0045]The present invention is further detailed in combination with reference to the accompanying drawings of the specification:

[0046]Such asFigure 1-4As shown, the porous sprinkler two-way stereo stirring synergies of the specifically implemented in the present invention mainly include a stirring shaft 1, a stereo mixer, a slurry, a slurry, a spray mouth 4, a drill bit 6.

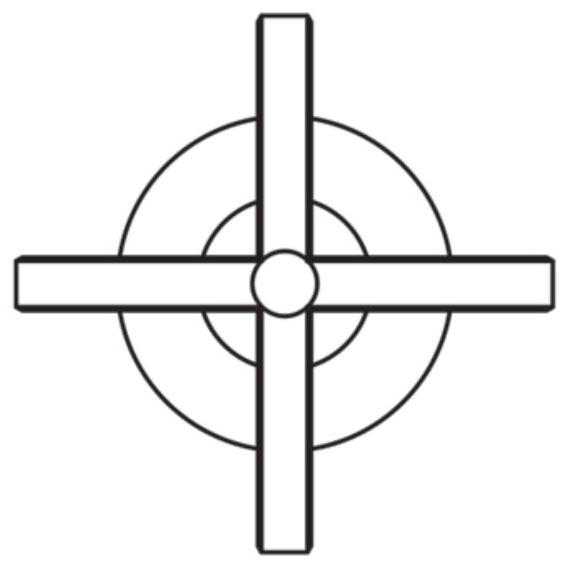

[0047]The stirring shaft 1 is hollow tubular and mounted on the drive unit, and the stirring shaft 1 is provided with a stereo mixing head and a drill bit 6; the stereo mixer is composed of horizontal stirring rod 3 and vertical stirred rod 2; level; The mixing rod 3 is divided into two layers of upper and lower layers, four of each layer, a cross-shaped distribution in the agitating shaft 1; the up and down end points of the vertical stirring rod 2 are connected to the agitating shaft 1, vertical stirred rod 2 distribution The four directions are consistent with the four directions of the horizontal to the stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com