Oil immersion machine for mechanical arm manufacturing and capable of achieving uniform oil immersion

A mechanical arm, uniform technology, applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problems of not being able to automatically immerse oil, not being able to clamp parts in different places, and not being able to dry the workpiece, etc. To achieve the effect of convenient and stable holding of oil for secondary use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

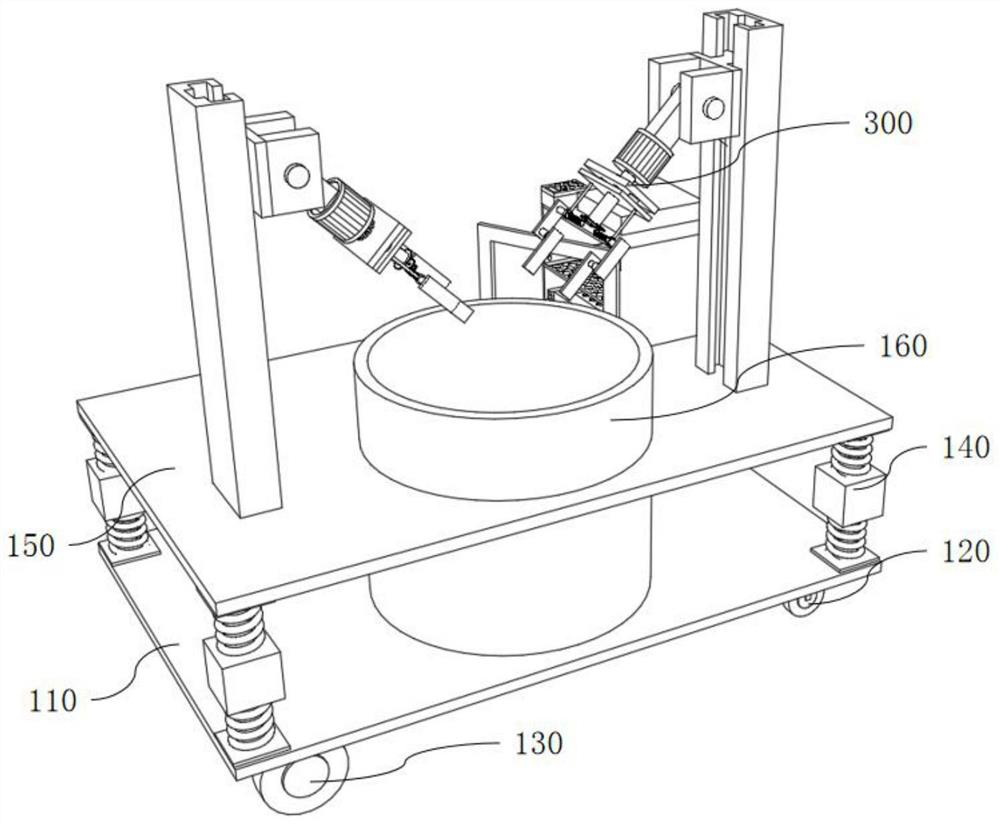

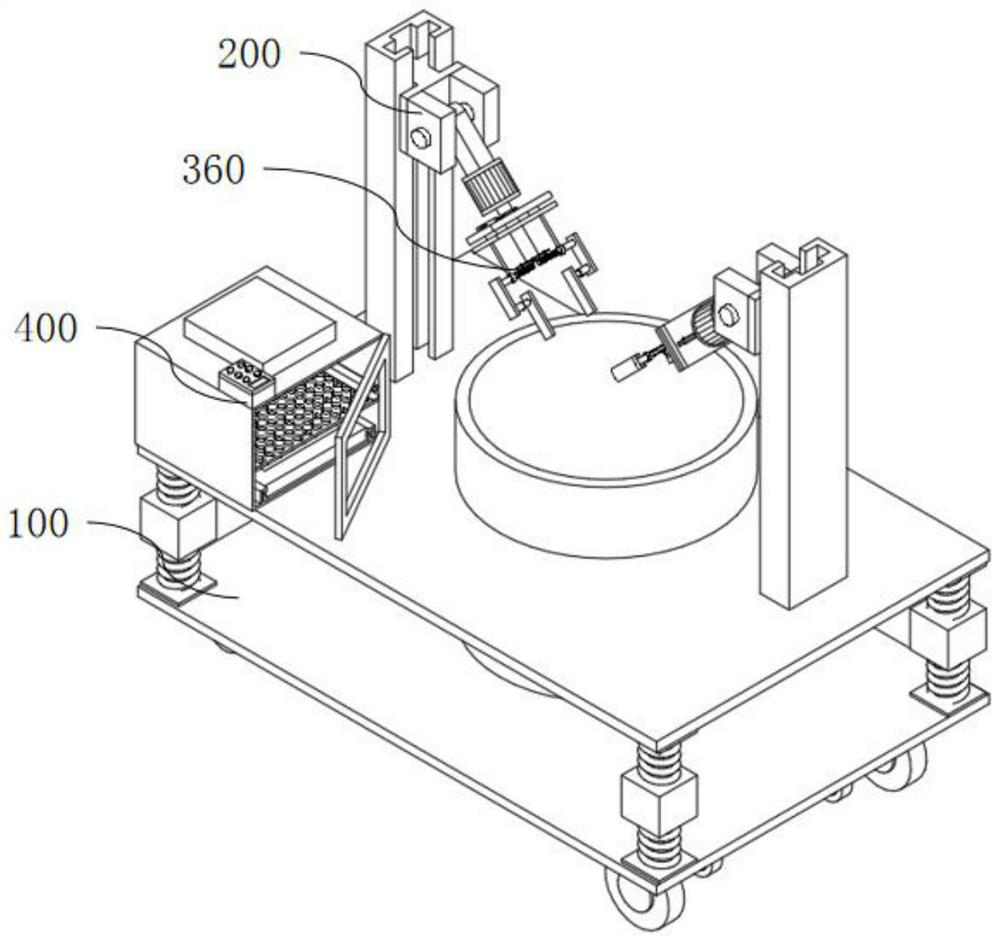

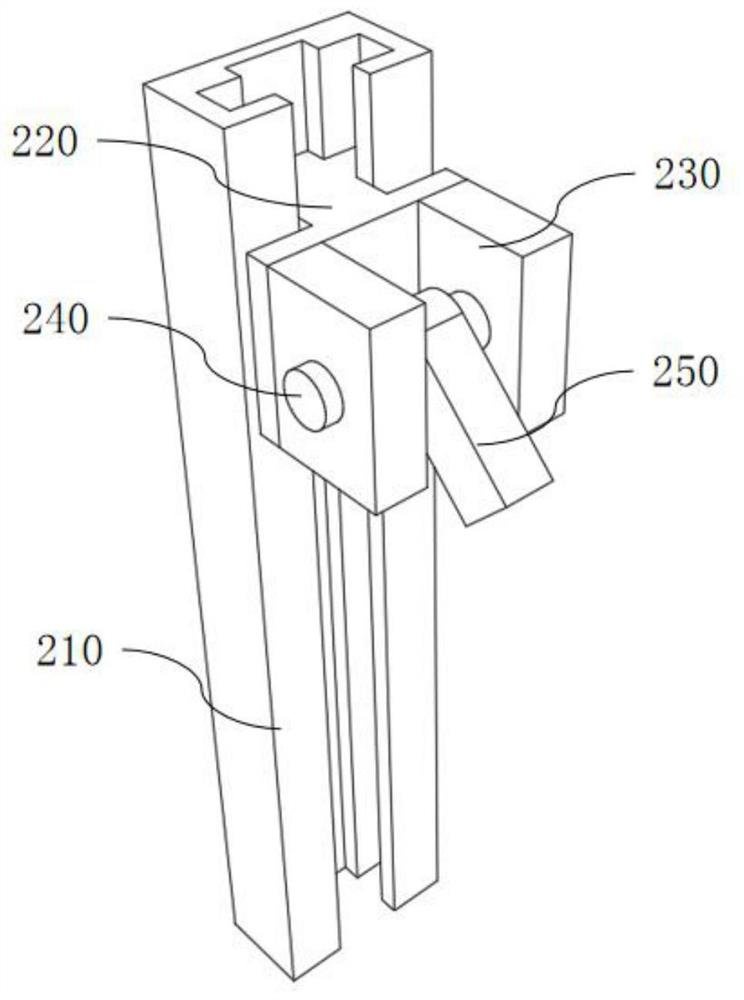

[0032] see Figure 1-8As shown, the present invention is an oil immersion machine for uniform oil immersion manufacturing, including a base 100, a sliding device 200, a clamping device 300, a drying box 400 and a collecting device 500. The base 100 includes an upper bottom plate 150 and an oil immersion Barrel 160, the upper surface of the upper base plate 150 is provided with mounting holes, the oil drum 160 is connected to the mounting holes, the sliding device 200 includes a slide rail 210 and a fixed block 250, the lower surfaces of the two slide rails 210 are connected with the upper surface of the upper base plate 150, and the clamping The device 300 includes a clamping motor 310, a fixed seat 320, a limit gear 330, a transmission gear set 350, a clamper 360, and a limiter 370. The surface on one side of the clamping motor 310 is connected to the surface on one side of the fixed block 250, and the clamping The motor 310 is provided with a rotating shaft, and the surface ...

Embodiment 2

[0040] see Figure 1-8 As shown, the present invention enables the clamping device 300 to slide along the slide rail 210 relying on the slider 220 by setting the sliding device 200, and the clamping device 300 can rotate around the circular shaft 240, which is convenient for adjusting the angle of oil immersion. The holding device 300 makes the clamping motor 310 provide power to the driving gear 340 to rotate, and the driving gear 340 transmits the power to the transmission gear set 350, so that the gear tooth bar 361 can slide in the slip ring 365, so that the splint 364 slides and the clamping plate 364 slides. The holder 360 can clamp workpieces of different sizes, and the stopper 370 can fix the rotating shaft after clamping to make the clamping more stable. By setting the drying box 400, the workpiece can be dried after oil immersion , the jet box 460 sprays hot air through the air distribution plate 470 and the air jet pipe 480 to accelerate the drying of the workpiece,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com