Automatic wiping and dehumidifying device for PVC film collection and storage

An automatic and lifting device technology, applied in the direction of coating, etc., can solve the problems of PVC film water mist residue, time-consuming and labor-intensive, etc., to achieve the effect of preventing odor and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

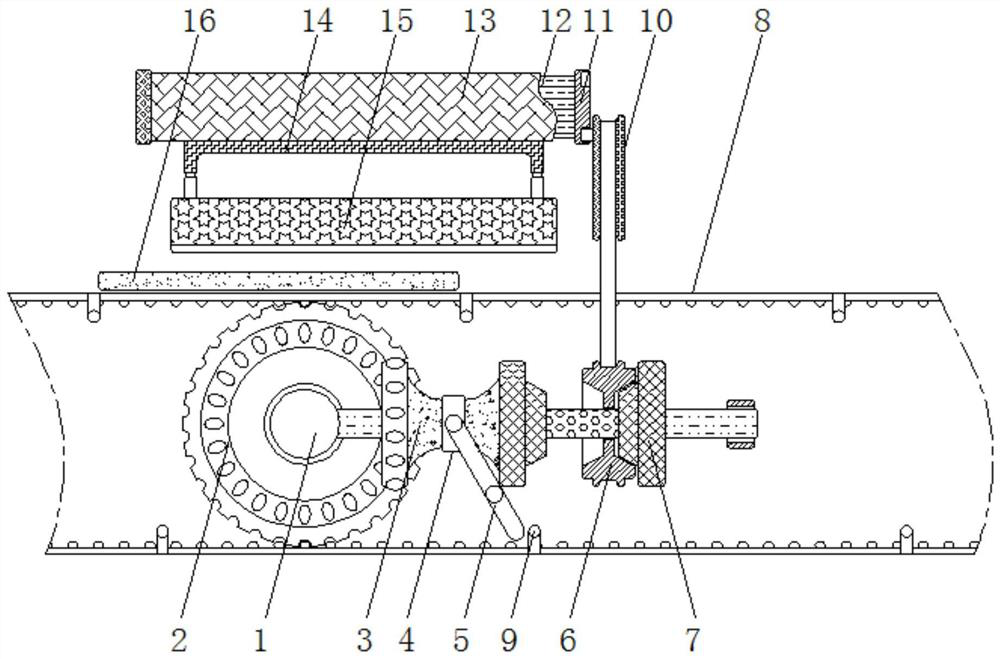

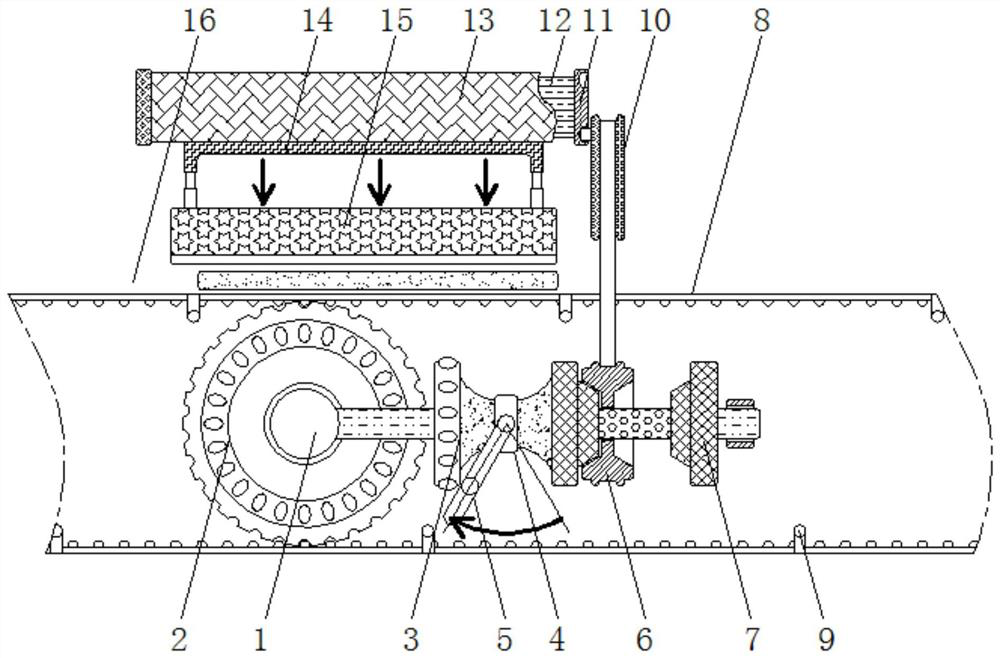

[0021]SeeFigure 1-2When a PVC film is stored, the dehumidification device is automatically wetted, including the fixed shaft 1, the surface rotation of the fixed shaft 1 is connected to the driven wheel 2, and the right side of the fixed shaft 1 is provided with a power moving wheel 3, power moving wheel. 3 The surface rotation is connected to a mixing ring 4, and the surface rotation of the mixing ring 4 is rotated and connected to the moving rod 5, and the power moving wheel 3 is provided with the guide wheel 6, and the right s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap