Formulations for advanced polishing pads

A formulation, precursor technology for manufacturing tools, other household appliances, additive manufacturing, etc., that can solve problems such as unpredictable performance, non-uniformity of polishing across substrate batches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

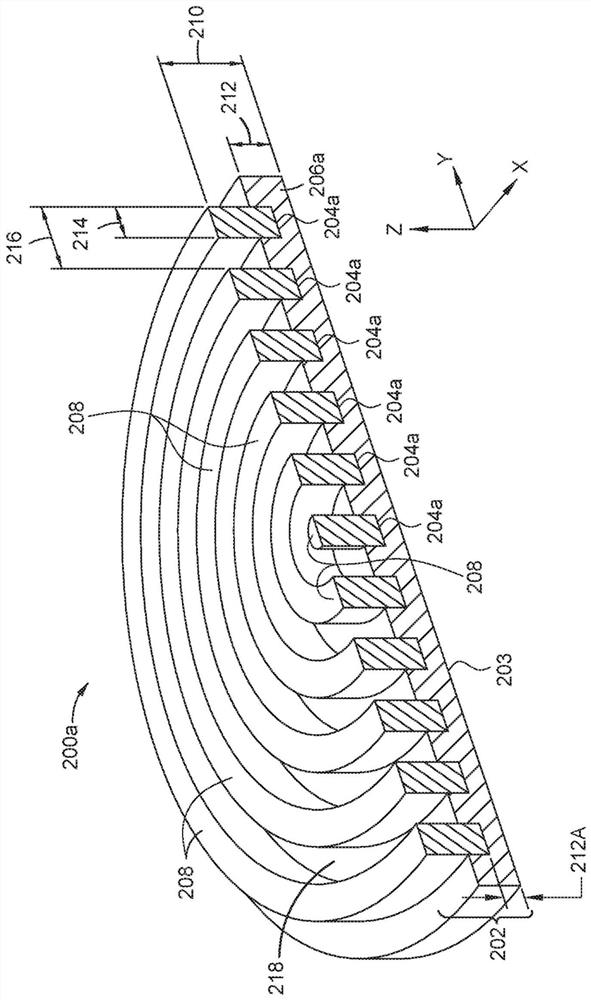

[0030] Embodiments disclosed herein generally relate to polishing articles and methods of making polishing articles for use in polishing processes. In particular, embodiments disclosed herein relate to porous polishing pads produced by processes that result in improved polishing pad properties and performance, including tunable performance. Additive manufacturing processes such as three-dimensional printing ("3D printing") processes provide the ability to create polishing pads with unique properties and attributes. Embodiments of the present disclosure provide advanced polishing pads with discrete features and geometries formed from at least two different materials from liquid polymer precursors, or resin precursor compositions containing a "resin precursor component" form. Resin precursor components include, but are not limited to, functional polymers, functional oligomers, monomers, reactive diluents, flow additives, curing agents, photoinitiators, one or more porosity form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com