Horizontal line casting machine

A pouring machine and horizontal line technology, which is used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of prolonging pouring time, affecting pouring efficiency of pouring machines, etc., so as to improve pouring efficiency, shorten pouring time, and set stable settings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

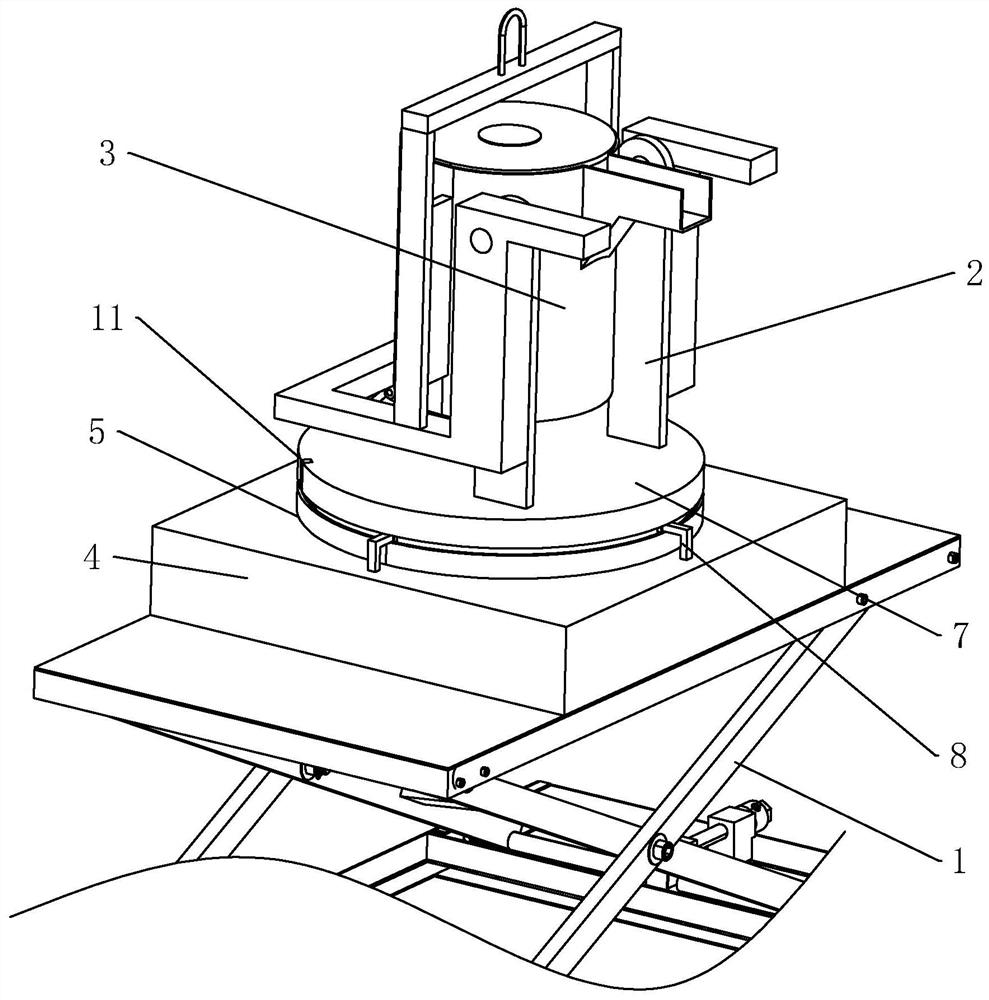

[0034] Embodiment: a kind of horizontal line pouring machine, refer to figure 1 , including a lifting frame 1, a pouring device 2 arranged on the lifting frame 1, and a ladle 3 arranged on the pouring device 2.

[0035] Wherein, the lifting frame 1 is fixedly connected with a mounting seat 4, and the mounting seat 4 is arranged in a cylindrical shape. A mounting groove 5 is opened on the top surface of the mounting base 4, and the inner cavity of the mounting groove 5 is arranged in a cylindrical shape.

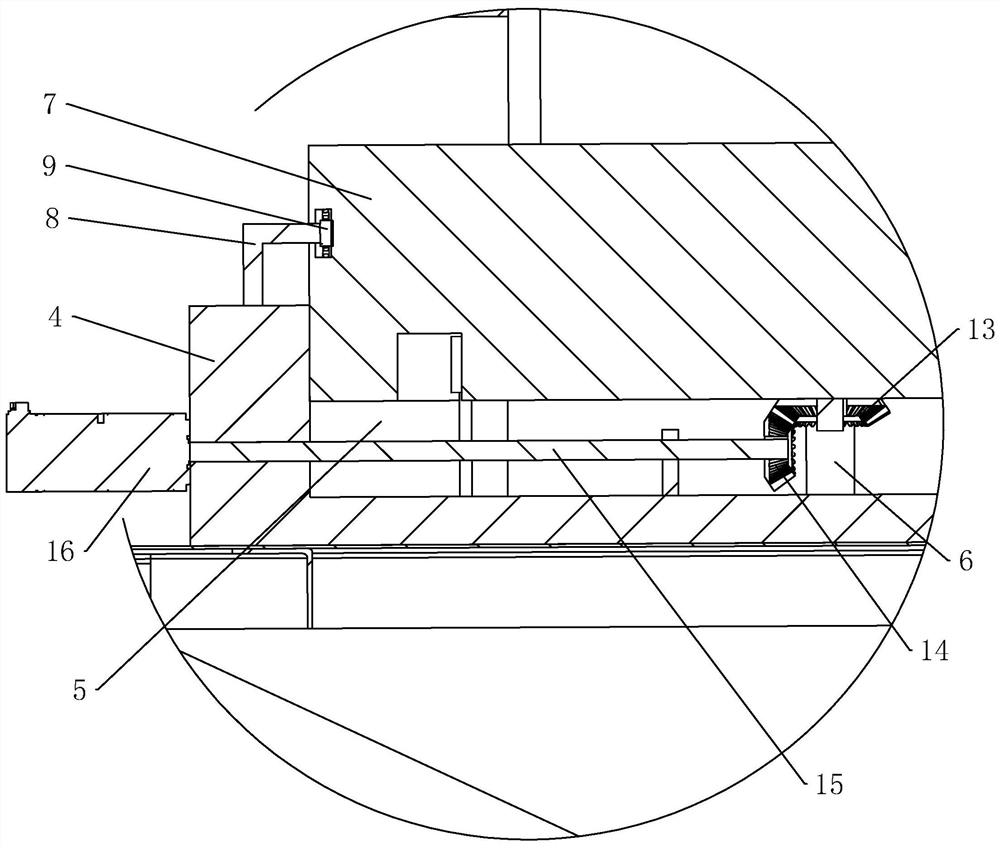

[0036] refer to figure 2 A rotating shaft 6 is rotatably connected to the side wall of the mounting groove 5 facing the notch, and the rotating shaft 6 is arranged along a direction perpendicular to the side wall. A turntable 7 is fixedly connected to the rotating shaft 6 , and the turntable 7 is rotatably connected in the installation groove 5 . The pouring device 2 is fixedly connected to the turntable 7 .

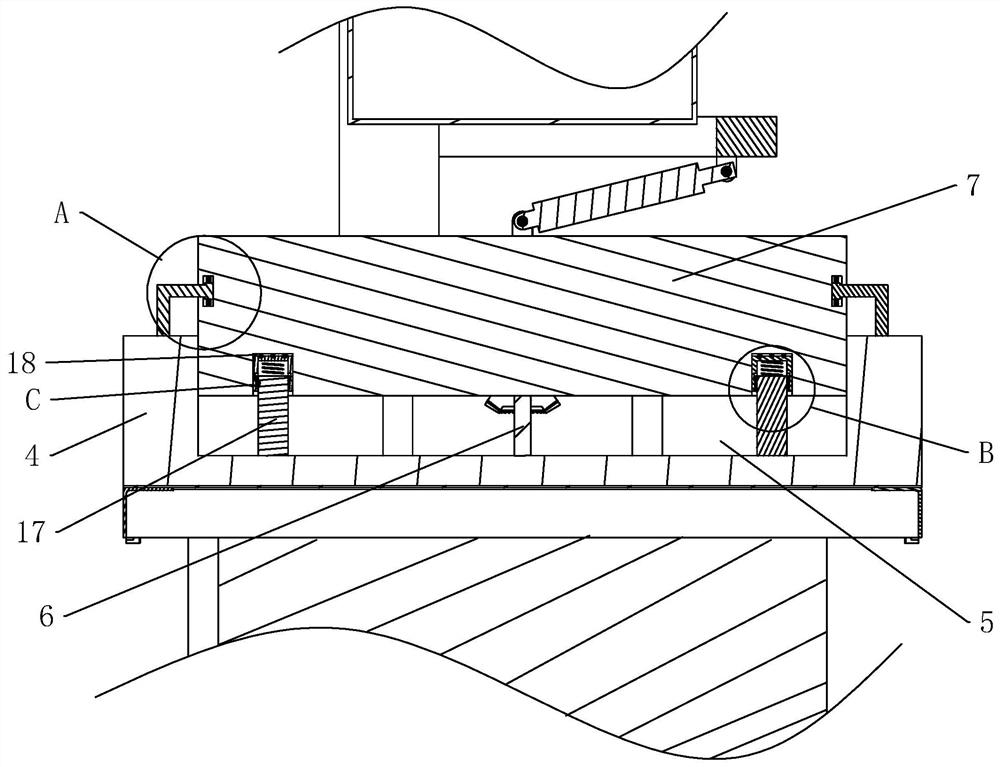

[0037] refer to image 3 and Figure 4 6 L-shaped connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com