Edge bonding machine scraper mechanism convenient to adjust

A technology of edge banding machine and scraper, which is applied to wood processing appliances, household components, etc., can solve the problem of unable to adjust the position of the scraper stably, and achieve the effect of reducing time and quickly changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

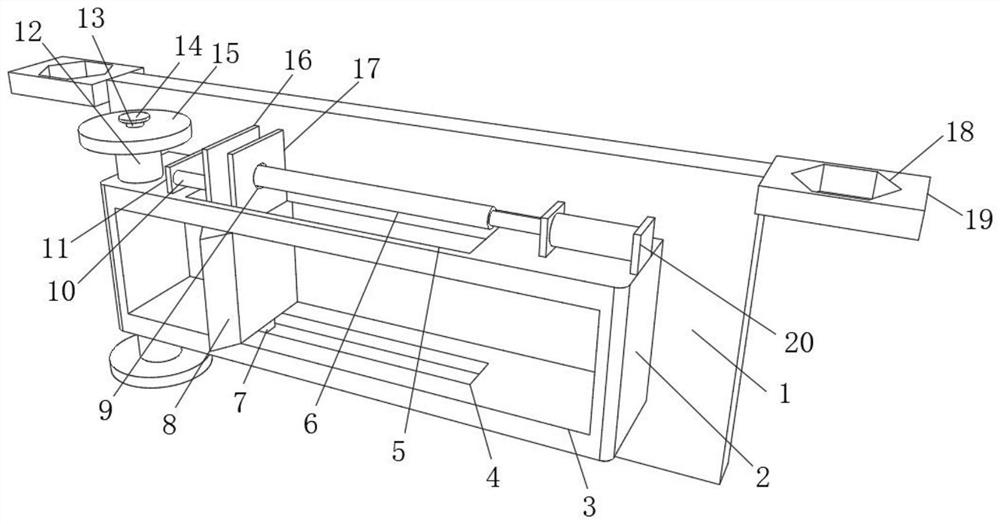

[0025] see Figure 1-2 , an edge banding machine scraper mechanism that is easy to adjust, including a mounting plate 1, the tops of the left and right sides of the mounting plate 1 are fixedly connected with connecting blocks 19, the inside of the connecting block 19 is provided with bolt holes 18, and the front side of the mounting plate 1 It is fixedly connected with the rear side of the fixed block 2, and the interior of the fixed block 2 is provided with a cavity 3, and the inner wall of the bottom of the cavity 3 is provided with a balance groove 4, and the length of the inner wall of the balance groove 4 is less than the length of the inner wall of the cavity 3, and the balance groove 4 A balance weight 7 is slidably connected to the inside of the balance weight 7. The top of the balance weight 7 runs through the balance groove 4 and extends into the cavity 3. The top of the balance weight 7 is fixedly connected to the bottom of the scraper 8, and the top and bottom of t...

Embodiment 2

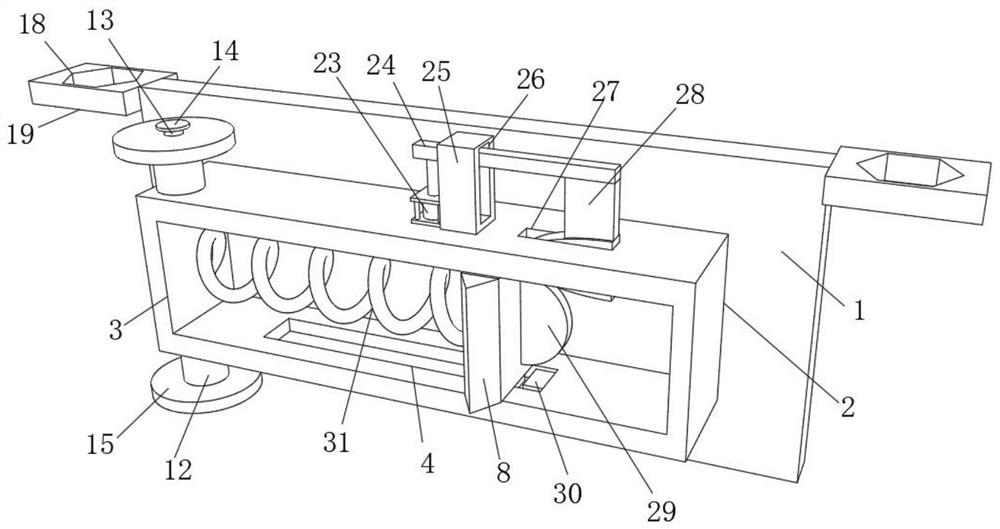

[0031] see Figure 3-4 , an edge banding machine scraper mechanism that is easy to adjust, including a mounting plate 1, the tops of the left and right sides of the mounting plate 1 are fixedly connected with connecting blocks 19, the inside of the connecting block 19 is provided with bolt holes 18, and the front side of the mounting plate 1 It is fixedly connected with the rear side of the fixed block 2, and the interior of the fixed block 2 is provided with a cavity 3, and the inner wall of the bottom of the cavity 3 is provided with a balance groove 4, and the length of the inner wall of the balance groove 4 is less than the length of the inner wall of the cavity 3, and the balance groove 4 A balance weight 7 is slidably connected to the inside of the balance weight 7. The top of the balance weight 7 runs through the balance groove 4 and extends into the cavity 3. The top of the balance weight 7 is fixedly connected to the bottom of the scraper 8, and the top and bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com