Elevator equipment

A lifter and equipment technology, which is applied to lifts, lift equipment in mines, transportation and packaging, etc., can solve the problems of high operating noise, reduced lift safety and reliability, and high lift energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

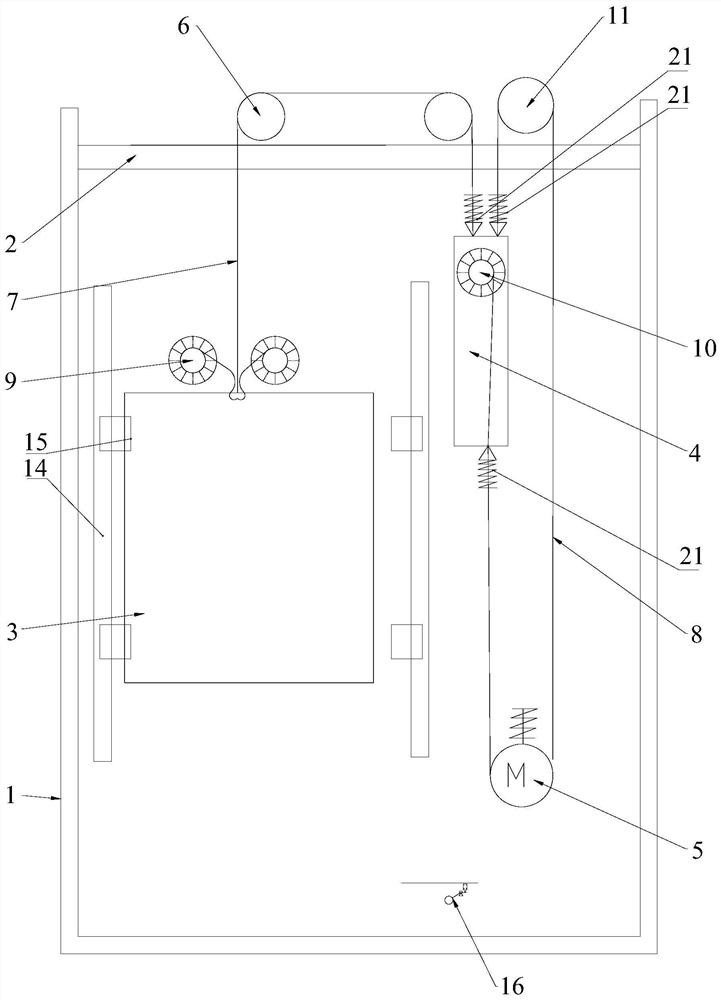

[0073] Such as figure 1 As shown, an elevator equipment includes a hoistway 1, a sky beam 2, a cage 3, a counterweight 4, a traction machine 5, a first guide wheel set 6 installed on the sky beam 2, a cage 3 and a counterweight 4 Located in the shaft 1; the traction machine 5 is located on the side of the counterweight 4;

[0074] The elevator equipment also includes a guide mechanism 14 for the cage 3 and the counterweight 4 to run up and down; the cage 3 or configuration 4 has an overspeed protection device 15 that cooperates with the guide mechanism 14, and the overspeed protection device 15 is fixed on the upper part of the cage 3 or lower;

[0075] The elevator equipment also includes a first traction rope 7, a second traction rope 8, a first code disk 9 and a second code disk 10, the first code disk 9 is fixed on the cage 3, and the second code disk 10 is fixed on the counterweight 4 Above, the first code disc 9 and the second code disc 10 are manual code discs or auto...

Embodiment 2

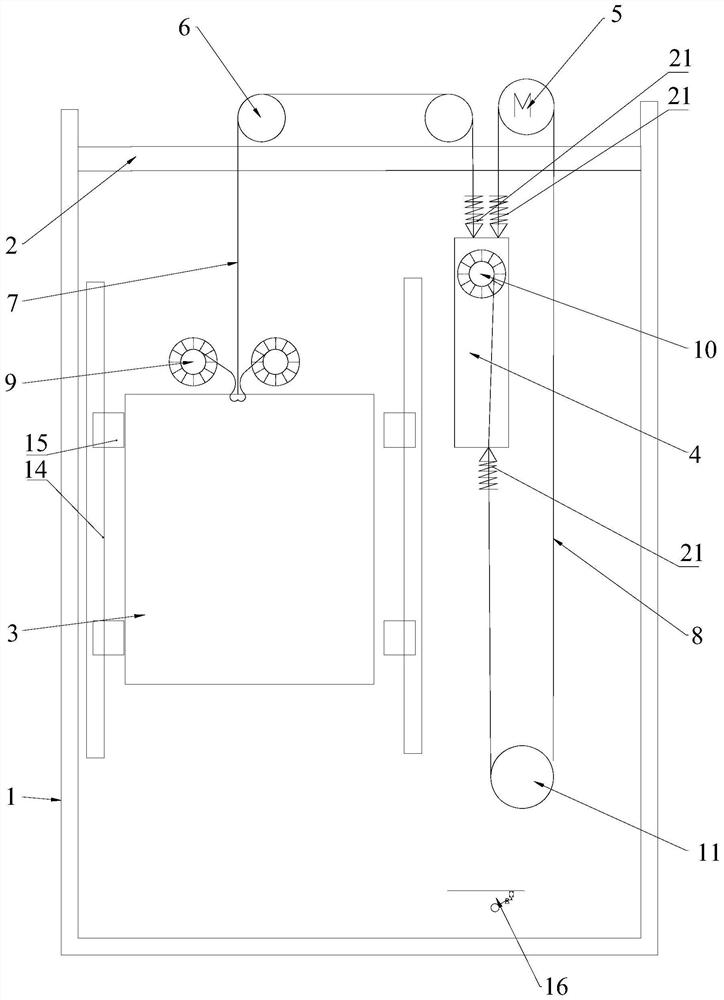

[0093] Such as Figure 5 As shown, this embodiment discloses a kind of elevator equipment, which includes a hoistway 1, a sky beam 2, a cage 3, a counterweight 4, a traction machine 5, and a first guide wheel set 6 installed on the sky beam 2, and the cage 3 and the counterweight 4 are located in the hoistway 1, the traction machine 5 is fixed on the bottom of the hoistway 1, on the wall or outside the hoistway 1, the fixed base of the traction machine 5 is equipped with a tensioning device, and the lower end of the cage 3 is installed with a first lower The wheel set 17, the second lower wheel set 18 is installed on the lower end of the counterweight 4, and the traction machine drives the cage 3 and the counterweight 4 to run alternately up and down by dragging the second traction cable;

[0094] The elevator equipment also includes a first traction rope 7, a second traction rope 8, a first code disc 9 and a second code disc 10, the first code disc 9 is fixed on the cage 3, a...

Embodiment 3

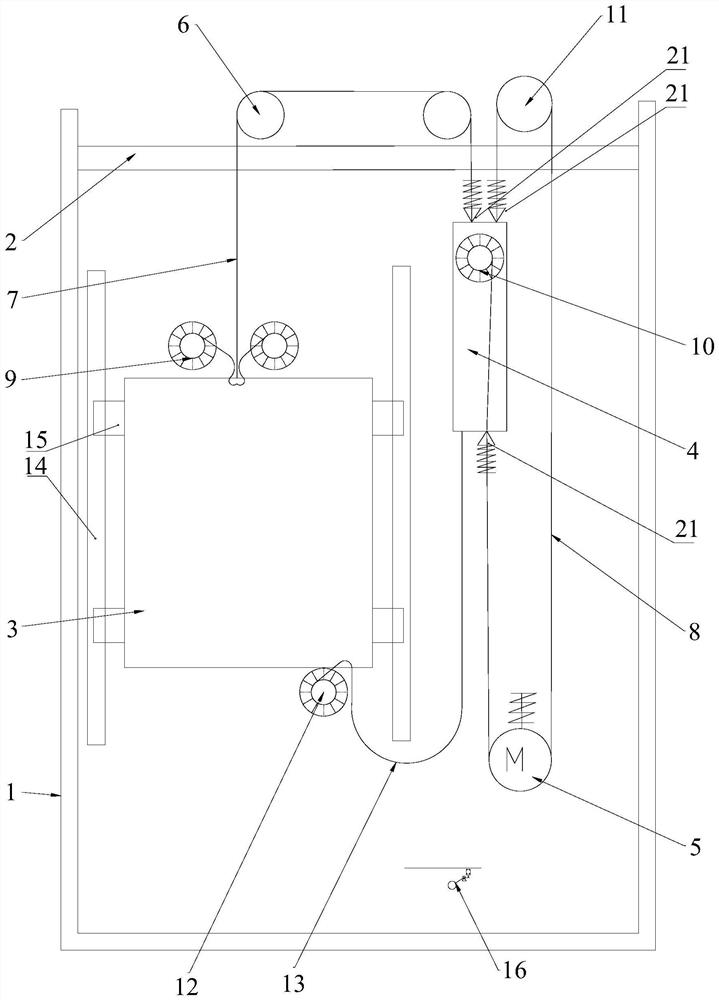

[0107] Such as Figure 7 As shown, this embodiment discloses a kind of elevator equipment, which includes a hoistway 1, a sky beam 2, a cage 3, a counterweight 4, a traction machine 5, and a first guide wheel set 6 installed on the sky beam 2, and the cage 3 and the counterweight 4 are located in the hoistway 1, the traction machine 5 is fixed on the bottom of the hoistway 1, on the wall or outside the hoistway 1, the fixed base of the traction machine 5 is equipped with a tensioning device, and the lower end of the cage 3 is installed with a first lower wheel set 17;

[0108] The elevator equipment also includes a first traction rope 7, a second traction rope 8, a first code disc 9 and a second code disc 10, the first code disc 9 is fixed on the cage 3, and the second code disc 10 is located at the cage 3 or One side of the counterweight 4 is fixed inside or outside the shaft 1; the first code disc 9 and the second code disc 10 are manual or automatic code discs;

[0109] O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com