Polysulfide Modified Epoxy Resin Coating and Its Application

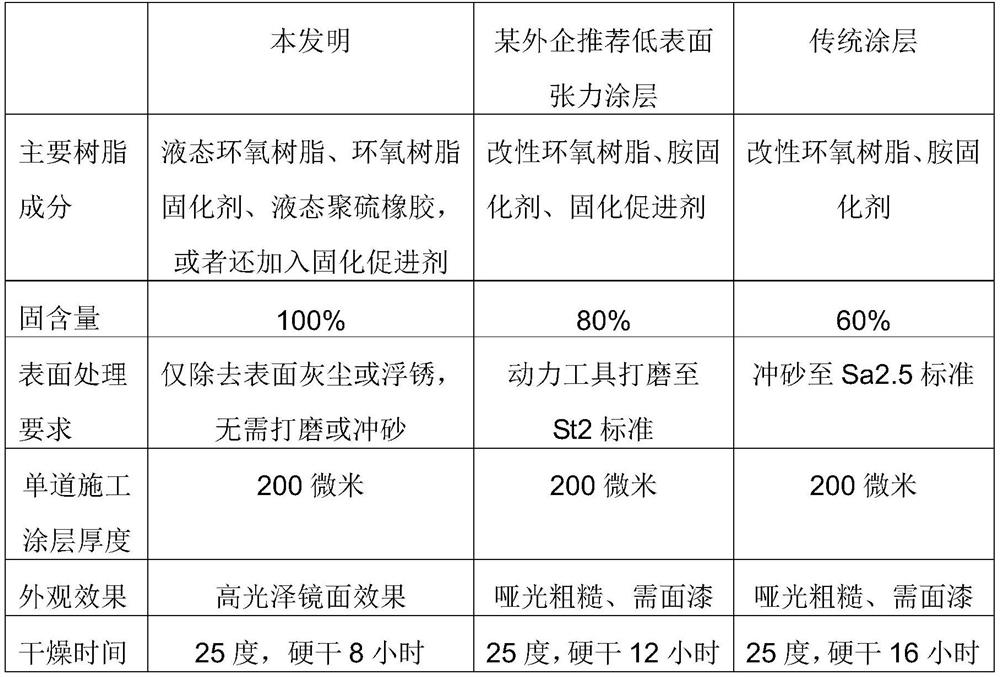

A polysulfide compound and epoxy coating technology, which is applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of increasing construction costs, achieve strong anti-corrosion performance, improve flexibility, and improve adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

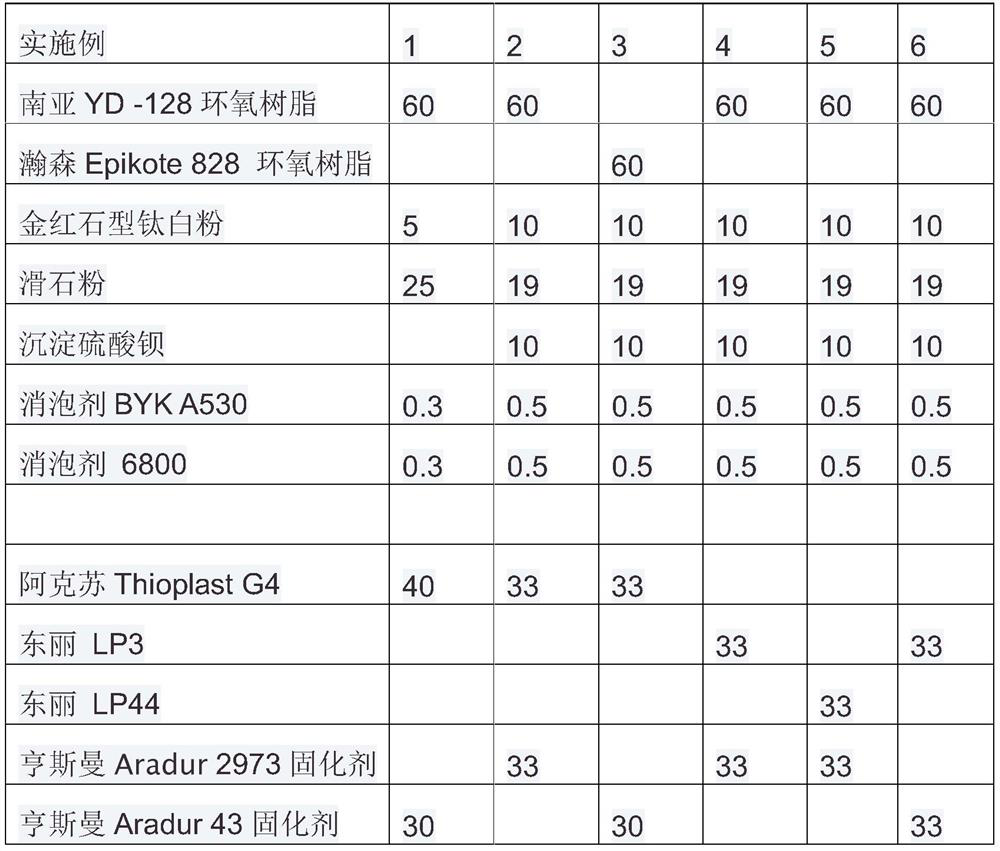

[0054] The configuration method of the polysulfide compound modified epoxy special coating provided in this implementation is as follows:

[0055] Component A: 60kg of liquid epoxy resin (such as Nanya YD-128 resin), put it in an iron container and stir at a medium speed, add 5kg of rutile titanium dioxide, 25kg of talcum powder, and 0.3kg of silicone disinfectant during the stirring process Foaming agent (such as BYKA530), 0.3kg silicone defoamer (such as defoamer 6800), high-speed dispersion for 30 minutes until the fineness reaches 80 microns.

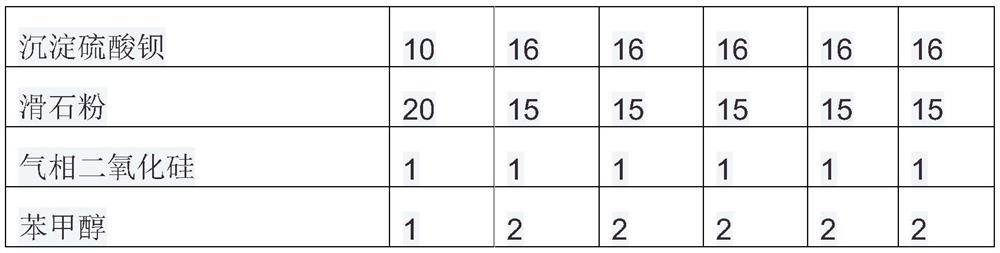

[0056] Component B: Polysulfide resin (such as Akzo Thioplast G4) 40Kg, epoxy resin curing agent (such as Huntsman Aradur 2973) 30kg, take 25kg of talcum powder, 10kg of precipitated barium sulfate, 1kg of fumed silica, and disperse at a high speed To fineness below 80 microns. Add 2kg of benzyl alcohol and stir evenly.

Embodiment 2

[0058] The configuration method of the polysulfide compound modified epoxy special coating provided in this implementation is as follows:

[0059] Component A: 60kg of liquid epoxy resin (such as Nanya YD-128 resin), put it in an iron container and stir at a medium speed, add 10kg of rutile titanium dioxide, 20kg of talcum powder, and 0.5kg of silicone disinfectant Foaming agent (such as BYKA530), 0.5kg silicone defoamer (such as defoamer 6800), high-speed dispersion for 30 minutes until the fineness reaches 80 microns.

[0060] Component B: polysulfide resin (Aksu Thioplast G4) 33Kg, epoxy resin curing agent (Hunsman Aradur 2973) 33kg, take 16kg of precipitated barium sulfate, 15kg of talcum powder, 1kg of fumed silica, and disperse at high speed until fine Degrees below 80 microns. Add 2kg of benzyl alcohol and stir evenly.

Embodiment 3

[0062] The configuration method of the polysulfide compound modified epoxy special coating provided in this implementation is as follows:

[0063] Component A: 60kg of liquid epoxy resin (such as Hexion Epikote 828), put it in an iron container and stir at a medium speed, add 10kg of rutile titanium dioxide, 20kg of talcum powder, and 0.5kg of silicone defoaming during the stirring process Agent (such as BYKA530), 0.5kg silicone defoamer (such as defoamer 6800), high-speed dispersion for 30 minutes until the fineness reaches 80 microns.

[0064] Component B: polysulfide resin (Aksu Thioplast G4) 33Kg, epoxy resin curing agent (Hunsman Aradur 43) 30kg, take 16kg of precipitated barium sulfate, 15kg of talcum powder, 1kg of fumed silica, and disperse at high speed until fine Degrees below 80 microns. Add 2kg of benzyl alcohol and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com