Knitted vamp with internal visual three-dimensional texture structure and manufacturing method of knitted vamp

A texture and three-dimensional technology, which is applied to the knitted shoe upper with internal visible three-dimensional texture structure and its production field, can solve the problem of reducing the warmth retention of the upper, the stability of the resilience, the fixed style of the upper, and the inability to display the effect of the upper, etc. problem, to achieve the effect of good aesthetic effect, strong three-dimensional sense and strong sense of layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

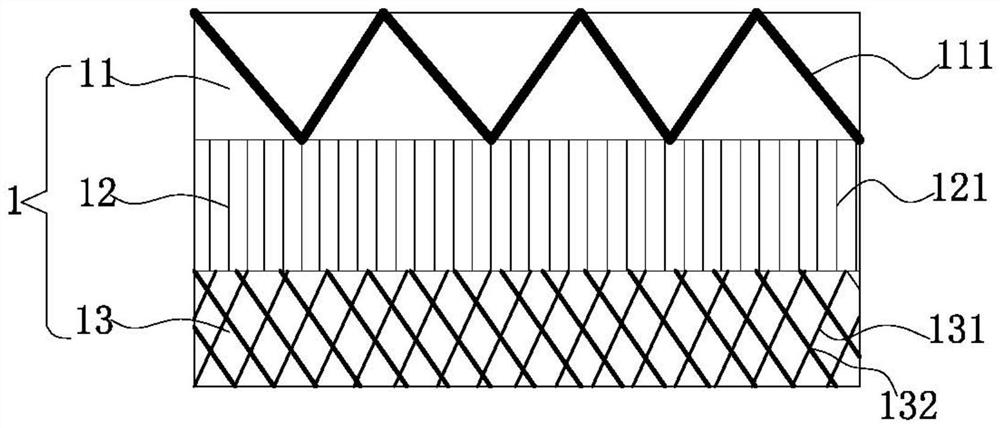

[0051] refer to figure 1 , figure 1 It is a structural schematic diagram of the knitted shoe upper with internal visible three-dimensional texture structure of the present invention.

[0052] The utility model relates to a knitted shoe upper with a visible three-dimensional texture structure inside, which includes a shoe upper book 1 which is integrally knitted.

[0053] The shoe upper body 1 includes a surface layer 11 , a three-dimensional texture layer 12 and a bottom layer 13 .

[0054] The surface layer 11 , the surface layer 11 is disposed above the three-dimensional texture layer 12 , the surface layer 11 includes a plurality of first yarns 111 , and the plurality of first yarns 111 are interwoven to form the surface layer 11 . The first yarn 111 is a transparent yarn. The first yarn 111 is a transparent TPU yarn.

[0055] The three-dimensional texture layer 12, the three-dimensional texture layer 12 is arranged between the surface layer 11 and the bottom layer 13, th...

Embodiment 2

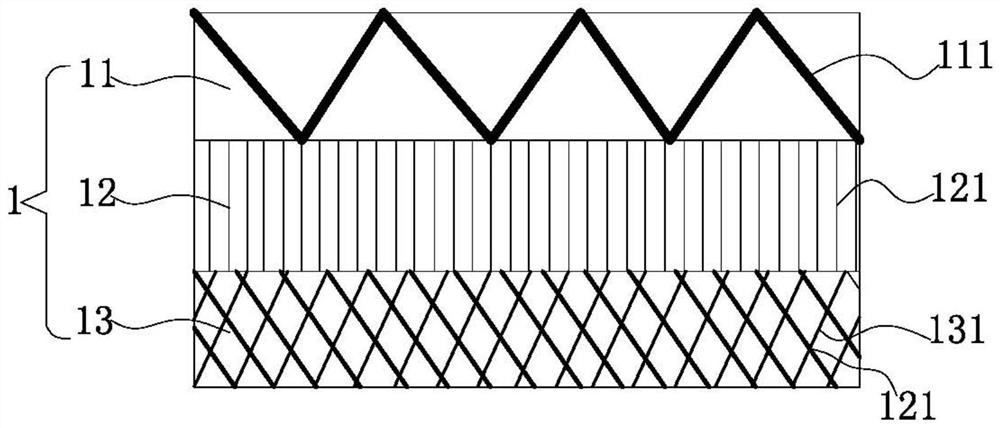

[0076] refer to figure 2 , figure 2 It is another structural schematic diagram of the knitted shoe upper with internal visible three-dimensional texture structure of the present invention.

[0077] The utility model relates to a knitted shoe upper with a visible three-dimensional texture structure inside, which includes a shoe upper book 1 which is integrally knitted.

[0078] The shoe upper body 1 includes a surface layer 11 , a three-dimensional texture layer 12 and a bottom layer 13 .

[0079] The surface layer 11 , the surface layer 11 is disposed above the three-dimensional texture layer 12 , the surface layer 11 includes a plurality of first yarns 111 , and the plurality of first yarns 111 are interwoven to form the surface layer 11 . The first yarn 111 is a transparent yarn. The first yarn 111 is a transparent TPU yarn.

[0080] The three-dimensional texture layer 12, the three-dimensional texture layer 12 is arranged between the surface layer 11 and the bottom la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com