Aluminum air battery electrolyte and preparation method thereof

An aluminum-air battery and electrolyte technology, which is applied in the direction of alkaline electrolyte, aqueous electrolyte, fuel cell half-cell and secondary battery-type half-cell, etc., can solve the problem of alkali creep, affecting the electrochemical activity of aluminum, battery Increased internal electrical loss and other issues, to achieve good electrochemical and thermal stability, improve battery performance, and reduce self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

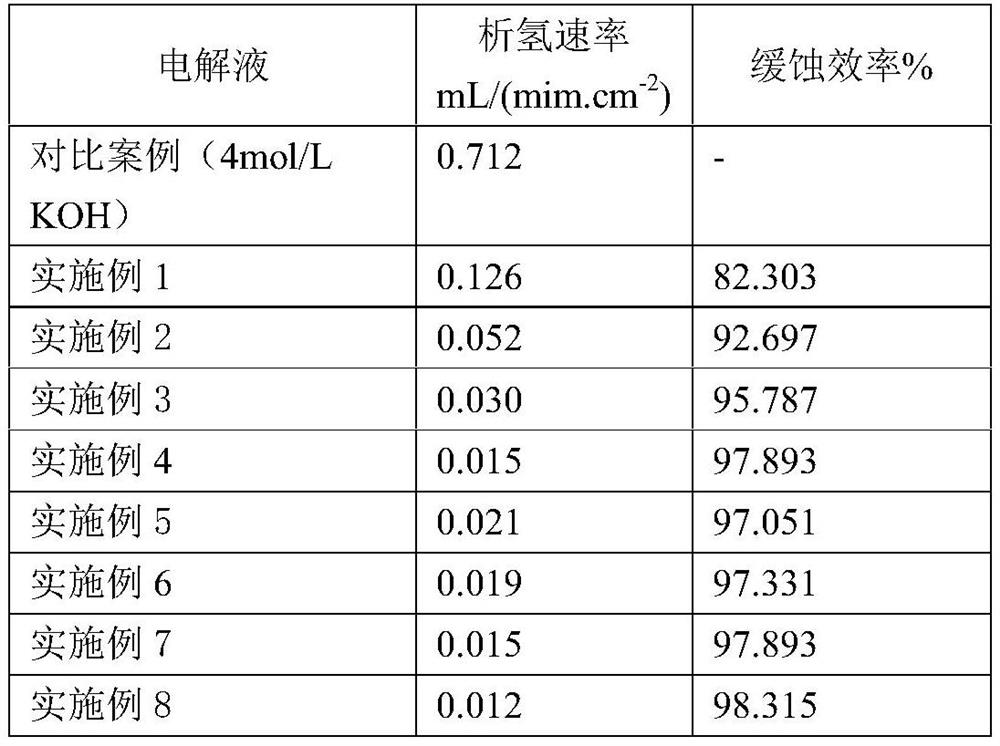

[0018] An aluminum-air battery electrolyte: Slowly add 0.5 mmol / L new ionic liquid corrosion inhibitor to 4 mol / L potassium hydroxide solution, and gradually stir and dissolve to obtain an aluminum-air battery electrolyte.

[0019] In the ionic liquid corrosion inhibitor: the cation is 1-octyl-3-methylimidazole, and the anion is trifluoromethanesulfonate TFO anion.

[0020] The corrosion inhibition efficiency of 99.9% pure aluminum sheets in the electrolyte was tested at 25°C by using a three-electrode system with a mercury / mercuric oxide electrode as a reference electrode by hydrogen evolution gas collection method, and the test time was 2 hours.

Embodiment 2

[0022] An aluminum-air battery electrolyte: Slowly add 1.0 mmol / L new ionic liquid corrosion inhibitor to 4 mol / L potassium hydroxide solution, and gradually stir and dissolve to obtain an aluminum-air battery electrolyte.

[0023] In the ionic liquid corrosion inhibitor: the cation is 1-octyl-3-methylimidazole, and the anion is trifluoromethanesulfonate TFO anion.

[0024] The corrosion inhibition efficiency of 99.9% pure aluminum sheets in the electrolyte was tested at 25°C by using a three-electrode system with a mercury / mercuric oxide electrode as a reference electrode by hydrogen evolution gas collection method, and the test time was 2 hours.

Embodiment 3

[0026] An aluminum-air battery electrolyte: Slowly add 1.5mmol / L new ionic liquid corrosion inhibitor into 4mol / L potassium hydroxide solution, and gradually stir and dissolve to obtain an aluminum-air battery electrolyte.

[0027] In the ionic liquid corrosion inhibitor: the cation is 1-octyl-3-methylimidazole and the anion of trifluoromethanesulfonate TFO.

[0028] The corrosion inhibition efficiency of 99.9% pure aluminum sheets in the electrolyte was tested at 25°C by using a three-electrode system with a mercury / mercuric oxide electrode as a reference electrode by hydrogen evolution gas collection method, and the test time was 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com