FRD diode with short reverse recovery time, and preparation method thereof

A reverse recovery time, diode technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of large forward voltage drop, no production line pollution, and short reverse recovery time of FRD diodes and other problems, to achieve the effect of reducing forward voltage drop, short reverse recovery time, and increasing current flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

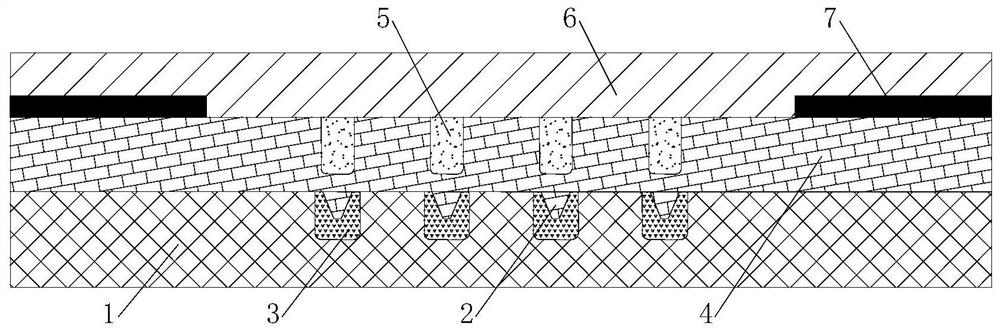

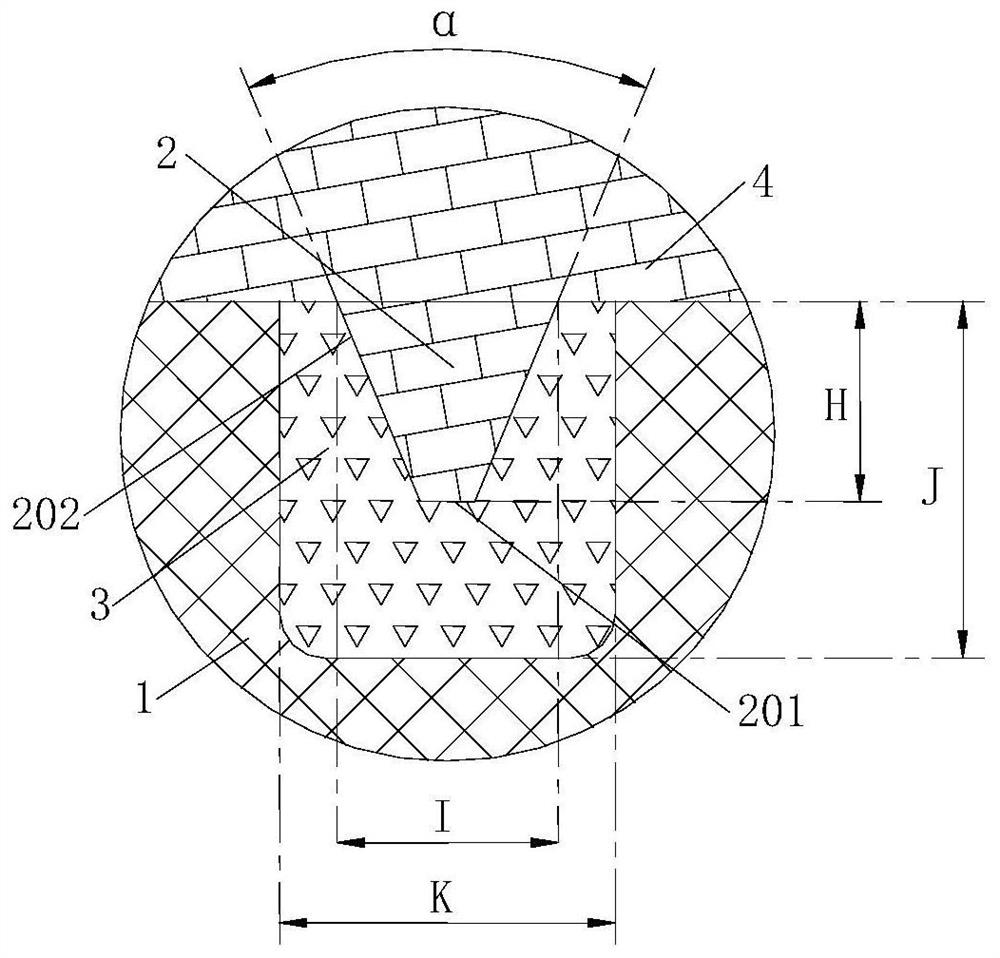

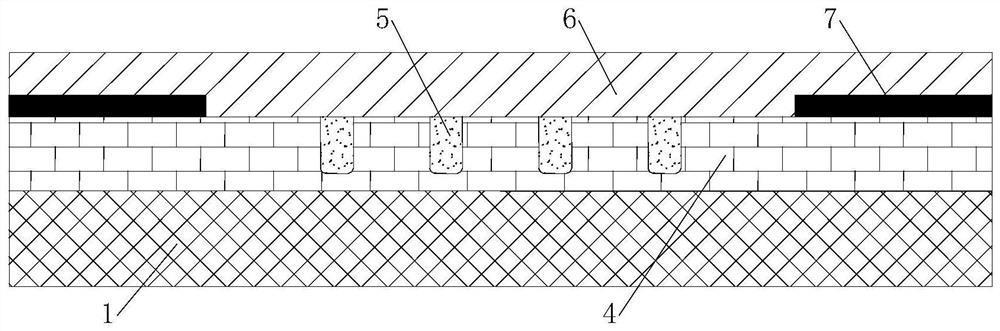

[0028] Example. A FRD diode with a short reverse recovery time, constructed as Figure 1-2 As shown, it includes an N-type silicon substrate layer 1, a number of grooves 2 are distributed on the surface of the N-type silicon substrate layer 1, a P+ substrate structure 3 is arranged inside the groove 2, and an N-type silicon substrate structure 3 is arranged outside the N-type silicon substrate layer 1. The epitaxial layer 4 , the inner side of the N-type silicon epitaxial layer 4 completely fills the trench 2 .

[0029] The groove 2 includes a bottom plane 201, and an inclined side wall 202 is arranged around the bottom plane 201. The cross-sectional shape of the side wall 202 is V-shaped, and the slope α of the side wall 202 is 45°.

[0030] The depth H of the bottom plane 201 is 0.5um, and the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com