Steam cooling separator structure

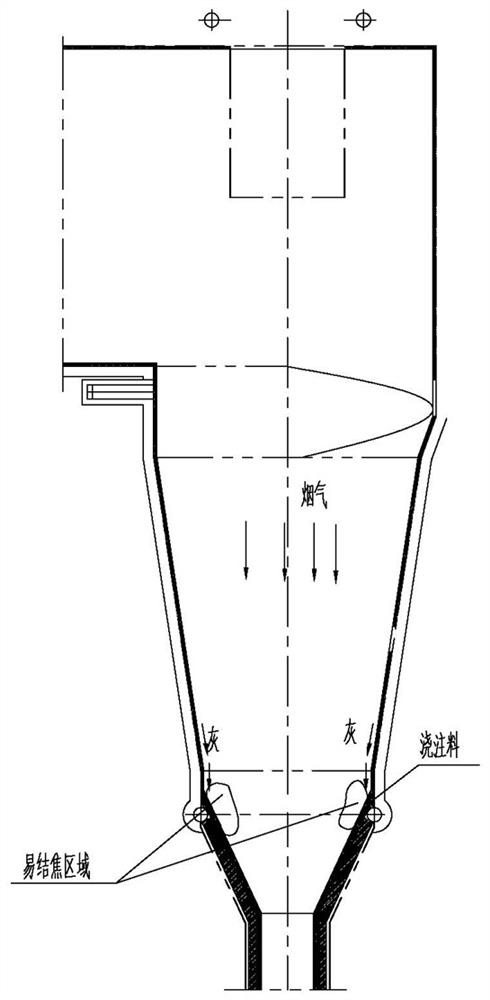

A technology of a gas-cooled separator and separator, which is applied in the direction of combustion type, combustion method, lighting and heating equipment, etc., can solve the problem of easy coking of the gas-cooled separator, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

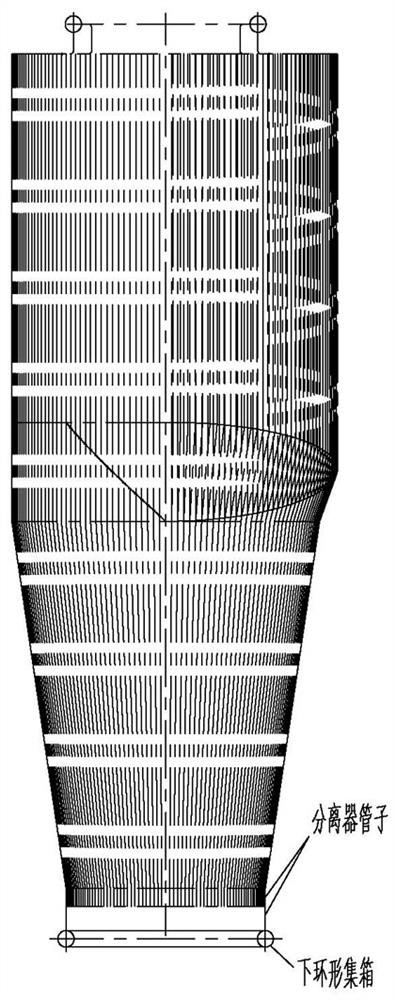

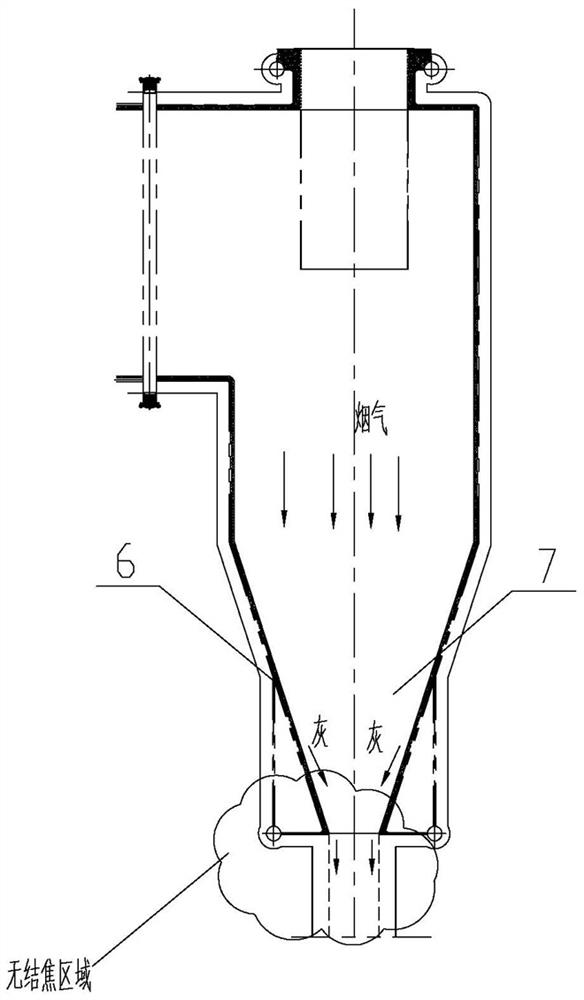

[0015] See image 3 , Figure 4 , Figure 5 , Image 6 As shown, a gas-cooled separator structure, which includes an upper annular header 1 and a lower annular header 2, the upper annular header 1 and the lower annular header 2 are connected by a separator pipe 3 arranged in a ring, The upper parts of adjacent separator pipes 3 are connected by flat steel. The separator pipes 3 include a first separator pipe 4 and a second separator pipe 5 arranged at intervals. The first separator pipe 4 includes a first upper vertical Section 4-1 and lower inclined section 4-2, the second separator pipe 5 includes a second upper vertical section 5-1, a middle inclined section 5-2, a lower vertical section 5-3, a first upper vertical section 4-1 The height corresponds to the second upper vertical section 5-1 and forms a cylindrical shape. The first upper vertical section 4-1 and the second upper vertical section 5-1 are connected to the upper annular header 2 through the upper elbow 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com