End face leveling system and method

An end-face and flat technology, which is applied in sorting, electrochemical generators, electrical components, etc., can solve the problems of low degree of automation, hitting the operator's hand with knocking blocks, and low safety, so as to avoid accidental injury operation People, high security, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0052]Example one

[0053]This embodiment provides an end-level leveling system that can be used to completely flattening the two end faces of the product, high efficiency and security. Example, the product can be a battery core.

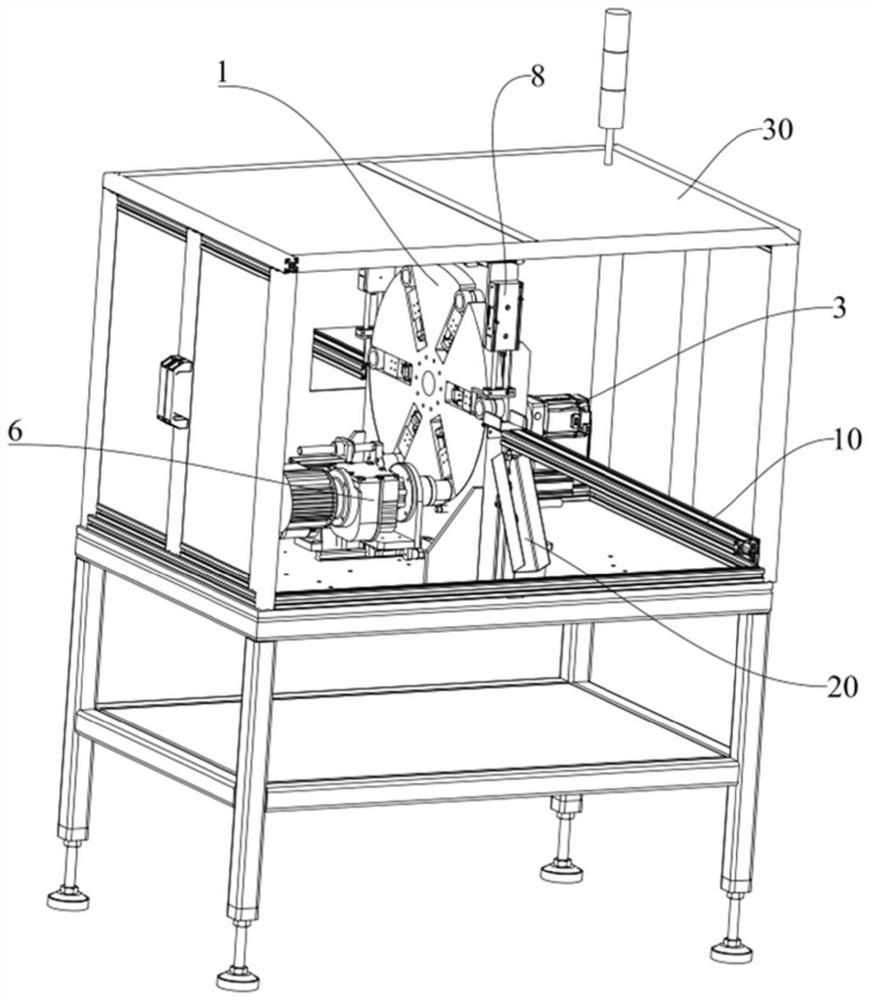

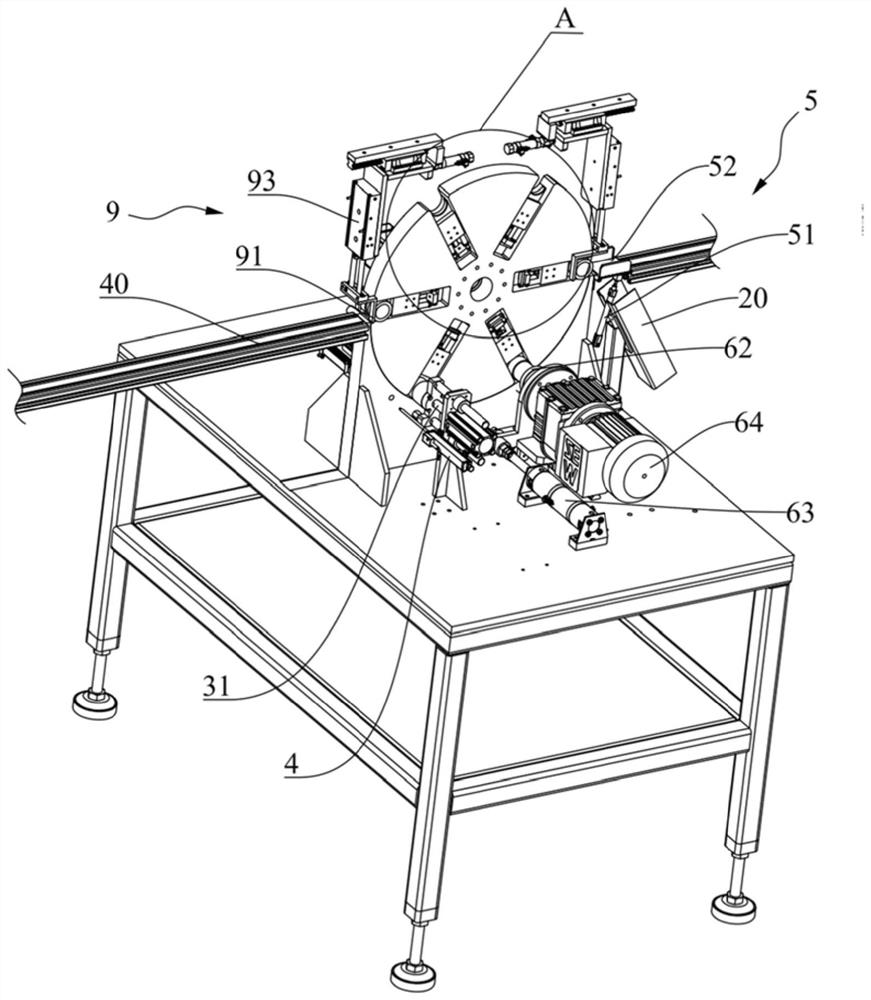

[0054]Such asFigures 1 to 10As shown, the end surface leveling system includes a frame structure 30, rotating a rotary disk 1 disposed on the frame structure 30, coupled to the rotary disc 1 and is used to drive the drive device 2 rotating the rotary disk 1, mounted on the frame structure 30 and used for Tap the tap device 3 of the end of the product 100, and the controller connected to the drive device 2 and the tap device 3.

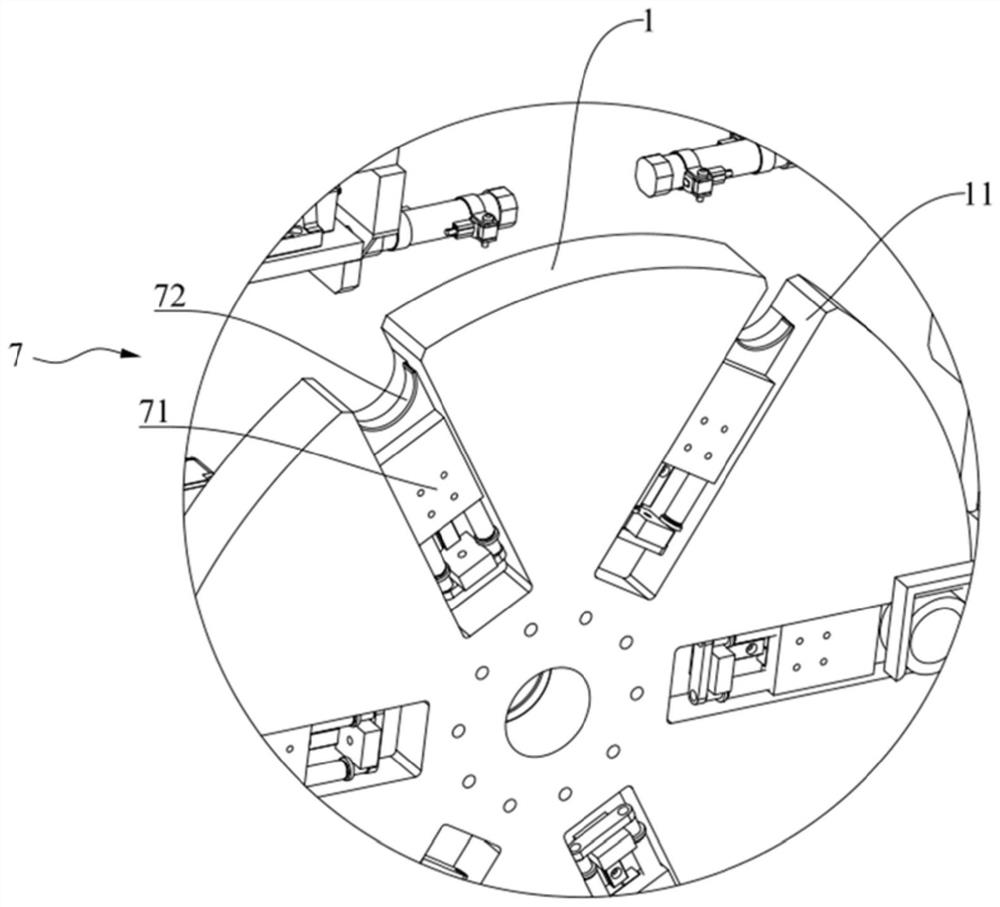

[0055]Among them, iffigure 2 withimage 3 As shown, the rotating disk 1 is provided with a product slot 11, and the product groove 11 extends radially radially, and the product groove 11 penetrates both sides of the rotary disk 1 in the thickness direction of the turntable disc 1. The product groove 11 is used to secure the product 100, and...

Example Embodiment

[0090]Example 2

[0091]This embodiment provides an end face-level method, applied to an end face leveling system in the first embodiment, and is performed by a controller in an end face leveling system, such asFigure 11 As shown, the end face-level method includes the steps of:

[0092]S1, after determining that the product tank 11 has a product 100, the control drive device 2 is activated to drive the rotational disk 1 to rotate, and when the turntable disk 1 is rotated to the product slot 11, the control drive device 2 is turned off.

[0093]In step S1, the controller determines whether there is product slot 11 in the product slot 11, and whether there is a product slot 11 at the first preset position, when the product slot 11 is present at the first preset position, the control drive device 2 is closed, so that Turn the disk 1 stationary.

[0094]S2, it is determined whether the product 100 is a product that is only one end, if yes, step S3 is performed; if not, step S4 is performed.

[0095]D...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap