Separating type engine shell with efficient heat dissipation function

A separate technology for the engine shell, which is applied in the direction of engine components, engine frame, engine cooling, etc., can solve the problems of shortening the service life of the engine, reducing the power of the engine, and reducing the service life of the engine, so as to improve the heat dissipation efficiency, The effect of avoiding shortened service life and reducing the chance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025]Example 1:

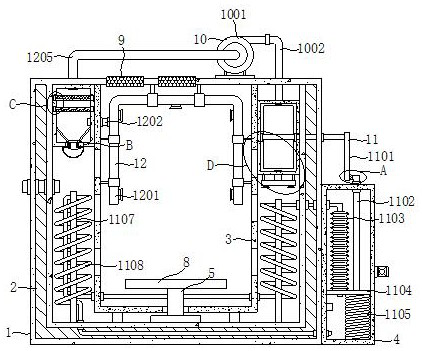

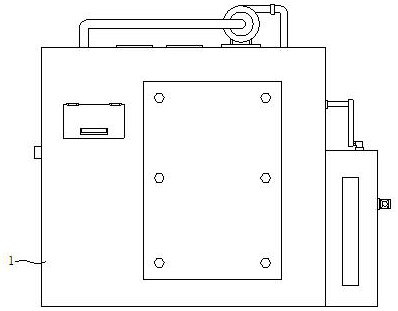

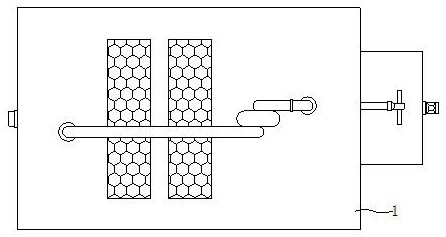

[0026]SeeFigure 1-7The present invention provides a technical solution: an engine housing having a separate high heat radiation function, comprising a housing 1, the housing 1 is provided with air cooling means 10, and a rapid cooling mechanism 11 dust mechanism 12, the housing 1 The top of the inner side is fixedly mounted having a U-shaped box 3, and two sets of filter layer plates 9 are mounted in the top of the housing 1, and the inner bottom of the casing 1 is rotated and mounted, and one end of the rotation shaft 5 extends to the U-box 3. the engine is mounted and fixed inside the fixing table 8, the side of the outer wall of the housing 1 is fixedly mounted crush boxes 4, 4 fixed to a side crush boxes attached to the filler tube, provided with a check valve on the feed tube, the housing 1 The inner top is fixedly mounted having a dust filter box 6, and the housing 1 thus is fixed to one side of the U-shaped box 3, and the housing 1 is attached to the housing 1...

Example Embodiment

[0028]Example 2:

[0029]SeeFigure 1-7On the basis of the first example, the air-cooling mechanism 10 includes a fan 1001, an output tube 1002, a shot rod 1003, a fan blade 1004, a connecting tube 1005, and a blower tube 1006, and the fan 1001 is fixed to the top, fan of the housing 1. The output terminal of 1001 is fixedly mounted, and one end of the output tube 1002 passes through the top of the housing 1 and extends to the inside of the fan leaf transmission case 7, and the side of the fan leaf transmission case 7 is rotated to mounting a turn rod 1003, transfer One end of the rod 1003 extends to one side of the housing 1, the outer wall of the rotary rod 1003 is fixedly mounted with two sets of fan blade 1004, and the bottom fixing of the fan blade transmission box 7 is fixedly mounted, the connecting tube 1005 and the fan leaf transmission case 7 The internal communication, one end of the connecting tube 1005 is fixedly mounted with a blower tube 1006, the interior of the connecti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap