Troubleshooting method and system for a multi-stage pumping station

A troubleshooting method and troubleshooting technology, applied in closed-circuit television systems, pump control, pump testing, etc., can solve problems such as fault discovery and processing, not in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0045] The present invention provides a method and system for troubleshooting a multistage pumping station.

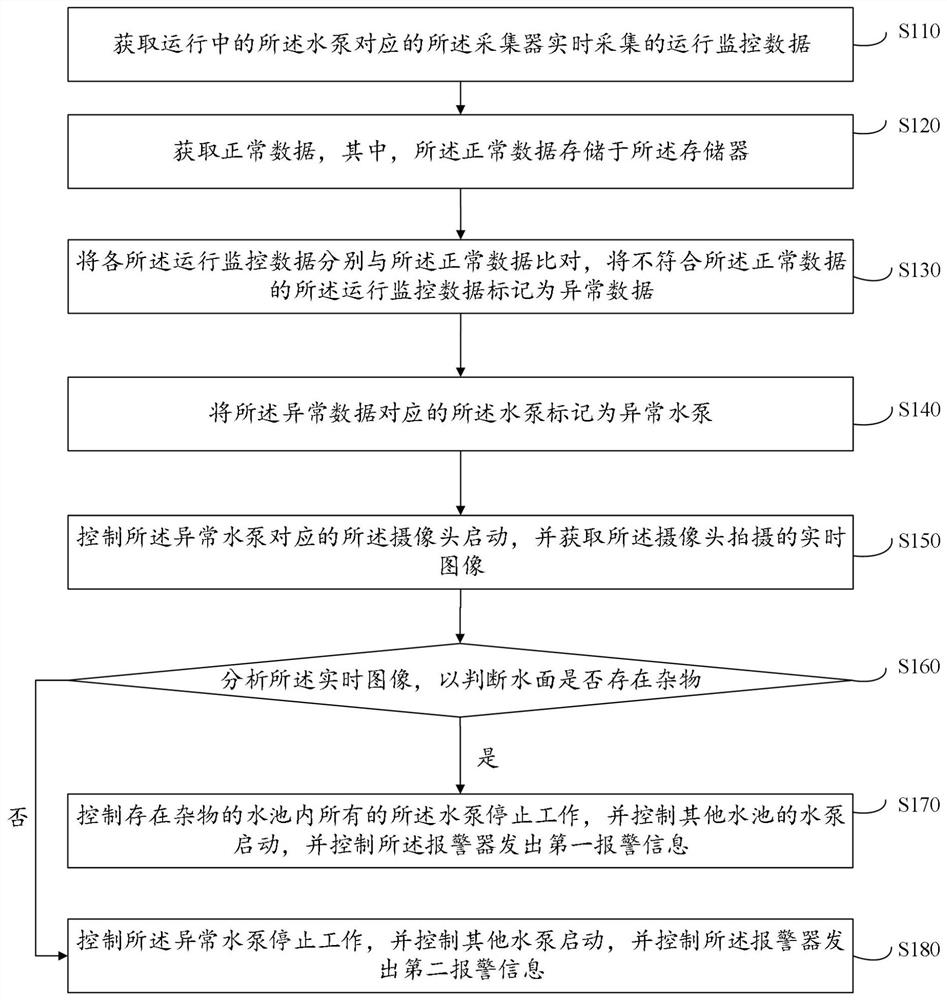

[0046] as attached figure 1 As shown, in the first embodiment of a method for troubleshooting a multi-stage pumping station proposed by the present invention, this embodiment is applied to a troubleshooting system for a multi-stage pumping station. There are water pumps in the pools; the fault elimination system of the multi-stage pumping station includes a server, a storage, a camera, a collector, an actuator and an alarm; the collector, the storage, the camera, the Both the actuator and the alarm are connected in communication with the server; the collector includes a first vibration sensor; the actuator is used to control the start and stop of different water pumps; the number of the collectors and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com