Preparation method of modified polypropylene film

A polypropylene film and modification technology, which is applied in chemical instruments and methods, film, film technology, etc., can solve the problem that it is difficult to meet the growing demand for surface multifunctionality, the inability to fully utilize free radicals, and the difficulty in controlling surface reactions, etc. problems, to achieve the effect of easy control of reaction degree, best separation performance and anti-pollution performance, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Immerse the PP film in 40 mL of DMF solution containing 800 mg of dopamine hydrochloride, 0.26 mL of BiBB, 0.3 mL of triethylamine and 200 mL of tris buffer at pH=8.5, stir and react for 24 hours, then take out the PP film, rinse with ethanol and dry to obtain the surface Deposited PP film of dopamine initiator (PP-PDA).

[0027] 2. Immerse the PP film obtained in step 1 into a solution containing 10 mg of cuprous bromide and 60 mg of tris(2-(dimethylamino)ethyl)amine (Me 6 TREN) in 10mL DMSO solution, under the protection of nitrogen, add 1g of hydrophilic monomer HEA, turn on the ultraviolet light, initiate the polymerization reaction with the hydrophilic monomer HEA, take out the PP film after 10h, rinse with ethanol and dry to obtain the surface Modified PP membranes grafted with hydrophilic monomers (PP-HEA).

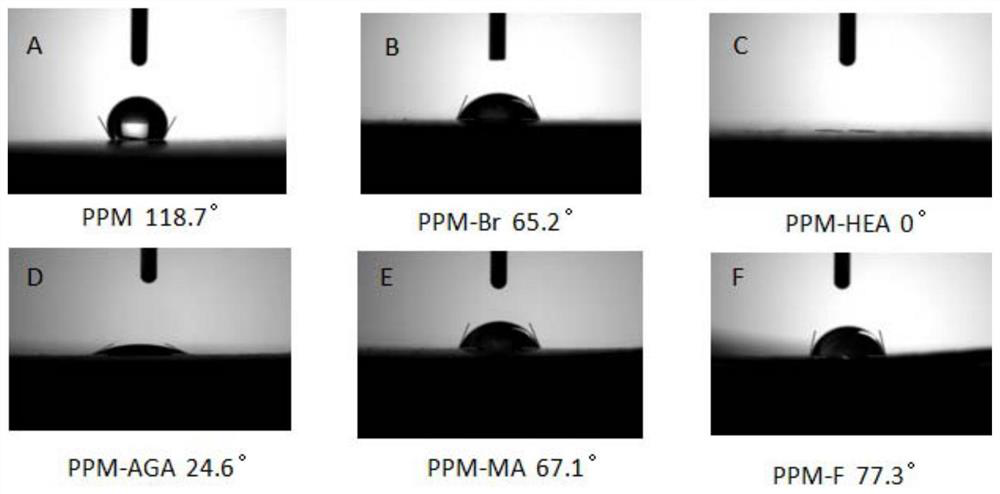

[0028] The static water contact angle diagram of the modified PP film prepared in this example is shown in figure 1 ,From figure 1 It can be seen that...

Embodiment 2

[0030] 1. Immerse the PP film in 40 mL of DMF solution containing 800 mg of dopamine hydrochloride, 0.26 mL of BiBB, 0.3 mL of triethylamine and 200 mL of tris buffer at pH=8.5, stir and react for 24 hours, then take out the PP film, rinse with ethanol and dry to obtain the surface Deposited PP film of dopamine initiator (PP-PDA).

[0031] 2. Immerse the PP film obtained in step 1 into a solution containing 10 mg of cuprous bromide and 60 mg of tris(2-(dimethylamino)ethyl)amine (Me 6 TREN) in 10mL DMSO solution, under the protection of nitrogen, add 1g of hydrophilic monomer AGA, turn on the ultraviolet light, initiate the polymerization reaction with the hydrophilic monomer AGA, take out the PP film after 10h, rinse with ethanol and dry to obtain the surface Modified PP membranes grafted with hydrophilic monomers (PP-AGA).

[0032] The static water contact angle diagram of the modified PP film prepared in this example is shown in figure 1 ,From figure 1 It can be seen that...

Embodiment 3

[0034] 1. Immerse the PP film in 40 mL of DMF solution containing 800 mg of dopamine hydrochloride, 0.26 mL of BiBB, 0.3 mL of triethylamine and 200 mL of tris buffer with a pH of 8.5. After stirring for 24 hours, take out the PP film, wash it with ethanol and dry it to obtain a surface Deposited PP film of dopamine initiator (PP-PDA).

[0035] 2. Immerse the PP film obtained in step 1 into a solution containing 10 mg of cuprous bromide and 60 mg of tris(2-(dimethylamino)ethyl)amine (Me 6 TREN) in 10mL DMSO solution, under the protection of nitrogen, add 1g of hydrophobic monomer MA, turn on the ultraviolet light, initiate the polymerization reaction with hydrophobic monomer MA, take out the PP film after 10h, rinse with ethanol and dry to obtain the surface grafted Modified PP Membrane (PP-MA) with Hydrophobic Monomer.

[0036] The static water contact angle diagram of the modified PP film prepared in this example is shown in figure 1 ,From figure 1 It can be seen that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com