Water-based self-repairing coating and coating layer for TPU invisible car cover

A self-healing, water-based technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of high health hazards for construction workers, harm to the health of construction workers, and narrow range of high and low temperature resistance. The effect of high drop angle and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The amount of raw materials used to prepare the water-based self-healing polyurethane resin material in this example is shown in Table 1.

[0060] The raw material consumption of table 1 embodiment 1 waterborne self-healing polyurethane resin

[0061] raw material parts by mass PTMEG2000 50 PCDL1000 8 Polymerized castor oil polyol D-290 5 TMXDI 10 IPDI 15 1,3-Propanediol 5 DMPA 3 Organic Bismuth Catalyst 0.5 DMEA 1 acetone 20 Deionized water 50

[0062] The preparation method of the water-based self-healing polyurethane resin of this example is as follows:

[0063] In a four-necked reaction flask equipped with a thermometer stirrer, add PTMEG2000, PCDL1000 and polymerized castor oil polyol D-290 according to the formula dosage in Table 1, heat up to 90-105°C, and vacuum dehydrate for 1.5-2 hours , lower the temperature to 50°C and install a condenser tube, add IPDI, TMXDI, 1,3-propanediol ...

Embodiment 2

[0065] The amount of raw materials used in the preparation of the water-based self-healing polyurethane resin material in this example is shown in Table 2.

[0066] The raw material consumption of table 2 embodiment 2 aqueous self-healing polyurethane resins

[0067] raw material parts by mass PTMEG3000 50 PCDL2000 8 Polymerized castor oil polyol D-290 5 TMXDI 10 IPDI 15 1,4-Butanediol 5 DMPA 3 Catalyst organotin 0.5 DMEA 1 acetone 20 Deionized water 50

[0068] The preparation method of the water-based self-healing polyurethane resin of this example is as follows:

[0069] In a four-necked reaction flask equipped with a thermometer stirrer, add PTMEG3000, PCDL2000 and polymerized castor oil polyol D-290 according to the formula dosage in Table 2, heat up to 90-105°C, and vacuum dehydrate for 1.5-2 hours , lower the temperature to 50°C and install a condenser tube, add IPDI, TMXDI, 1,4-butanediol...

Embodiment 3

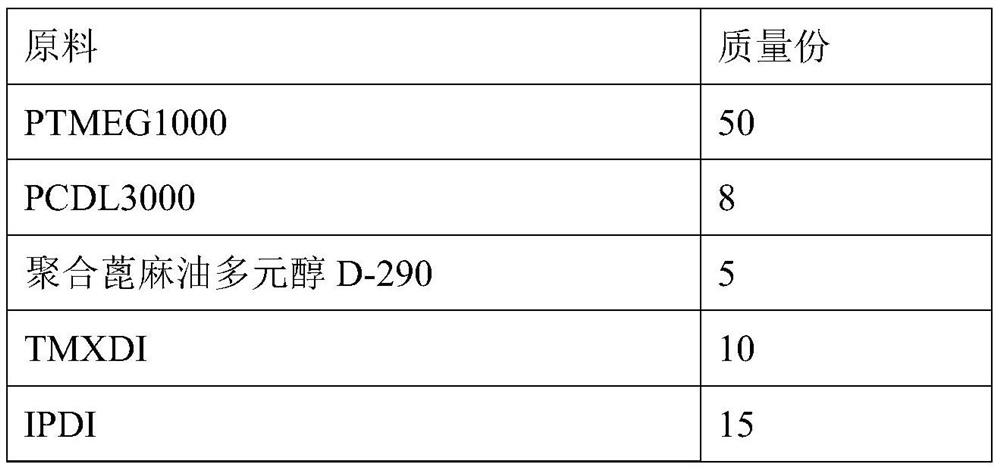

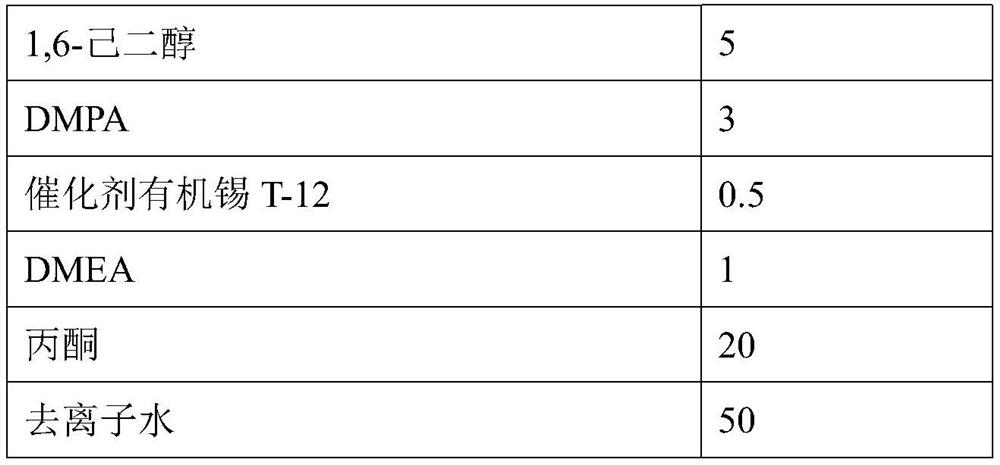

[0071] The amount of raw materials used to prepare the water-based self-healing polyurethane resin material in this example is shown in Table 3.

[0072] The raw material consumption of table 3 embodiment 3 waterborne self-healing polyurethane resins

[0073]

[0074]

[0075] The preparation method of the water-based self-healing polyurethane resin of this example is as follows:

[0076] In a four-necked reaction flask equipped with a thermometer stirrer, according to the formula dosage in Table 3, add PTMEG1000, PCDL3000 and polymerized castor oil polyol D-290 to heat up to 90-105 ° C, vacuum dehydration for 1.5-2 hours , lower the temperature to 50°C and install a condenser tube, add IPDI, TMXDI, 1,6-hexanediol and organotin T-12 catalyst, pass in nitrogen, keep warm at 70°C for 1 hour, then slowly raise the temperature to 80-85°C, keep warm 3.5-4 hours. Then add DMPA slowly, raise the temperature to 85-105°C, and then keep it warm for 1-1.5 hours until the detected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Drop angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com