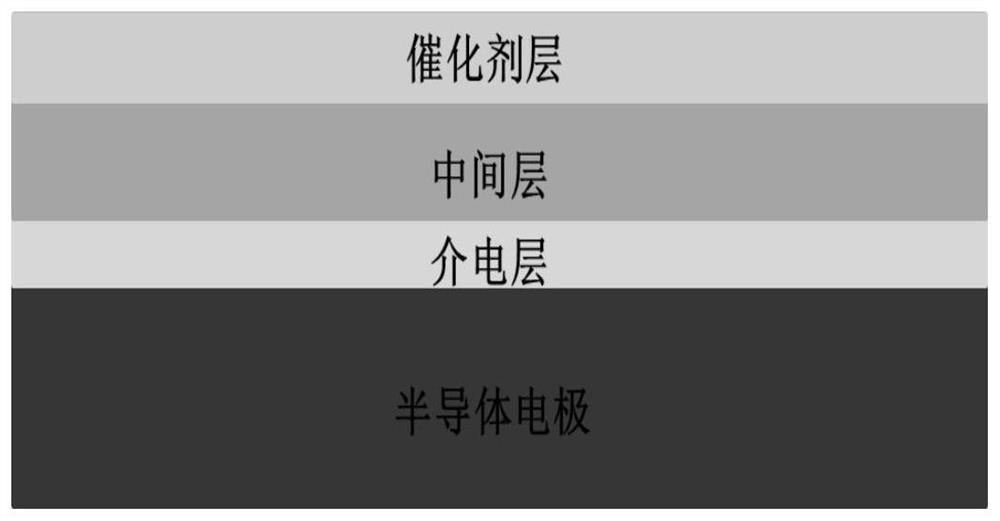

A method for improving the stability and conversion efficiency of narrow-bandgap semiconductor photoanodes

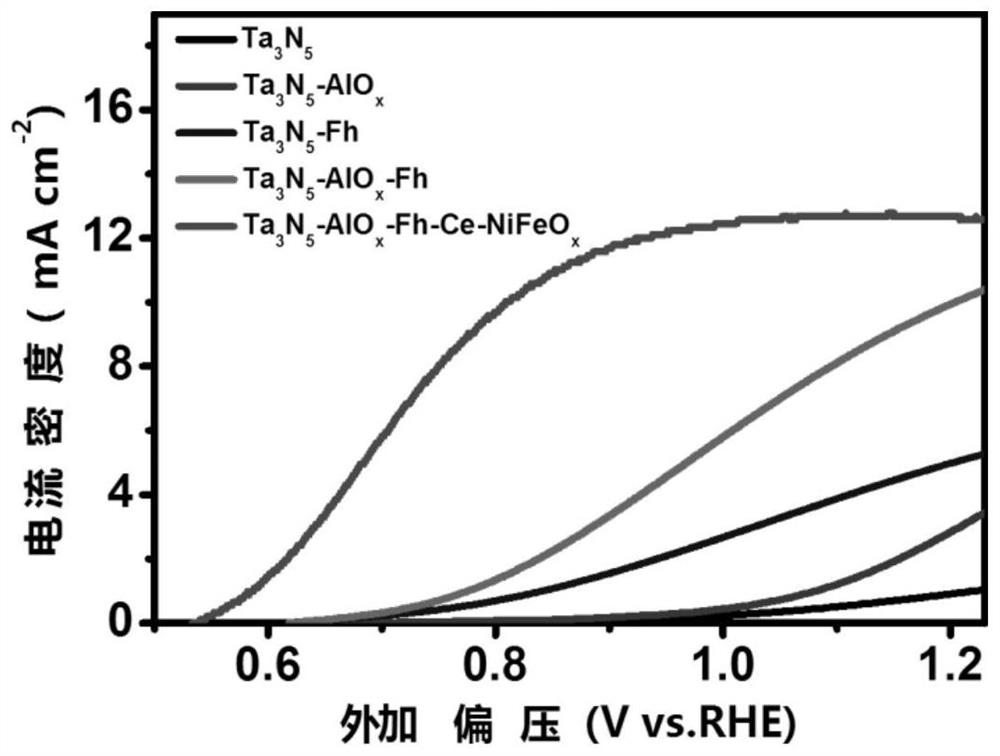

A conversion efficiency, photoanode technology, applied in the field of photocatalytic water splitting, can solve the problems of photocorrosion, limited application, instability, etc., and achieve the effect of improving injection efficiency, good hole storage effect, and reducing overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] Anodizing:

[0032] Configuration contains 0.15M NH 4 Ethylene glycol electrolyte of F and 1vol% ultrapure water, tantalum foil as anode, and platinum sheet as cathode. Maintained at 40-50V bias for 10min, the solution was stirred at 120rpm and kept circulating water cooling. The resulting sample was kept in a muffle furnace at 400 °C for 30 min.

[0033] Hydrothermal:

[0034] Configure 2M NaOH solution in a hydrothermal kettle, place tantalum foil at the bottom of the hydrothermal kettle, seal the hydrothermal kettle well and keep it at 200°C for 24 hours. After the reaction was completed and the temperature was naturally lowered to room temperature, the samples were taken out, rinsed with ultrapure water, ultrasonically treated in absolute ethanol for 1 min, and dried for later use.

[0035] High temperature nitriding:

[0036] NaTaO after heating the water 3 Put the sample into a quartz boat and put it into a horizontally placed quartz tube, and inject 250mLmi...

Embodiment 2

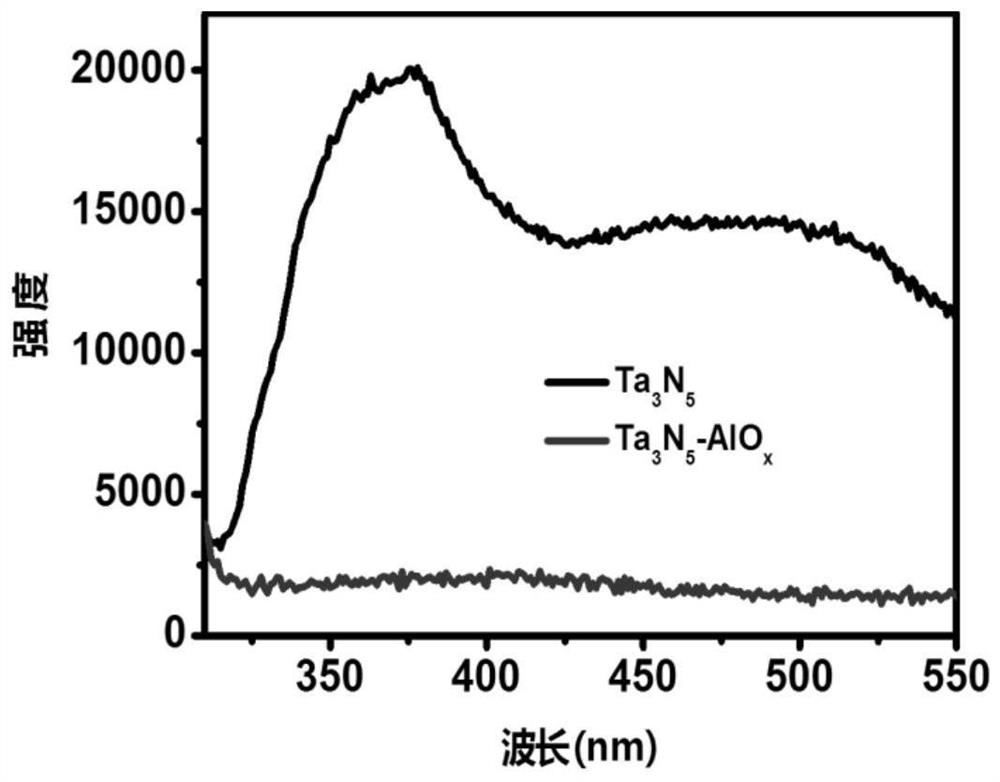

[0038] This example illustrates the implementation of preparing an aluminum oxide dielectric layer on the surface of a photoanode:

[0039] The atomic layer deposition (ALD) method is used, trimethylaluminum (TMA) is used as an aluminum source, water is used as an oxygen source, and the use temperature of the aluminum source is room temperature. The electrode 1 was placed in a reaction chamber at 150°C, the pulse time of the aluminum source was 0.01s, the pulse time of the oxygen source was 0.02s, and the growth thickness was 3nm controlled by the number of ALD cycles to obtain the electrode 2.

Embodiment 3

[0041] This example illustrates the implementation of preparing a titanium oxide dielectric layer on the surface of the photoanode:

[0042] The atomic layer deposition (ALD) method was used, tetrakis(dimethylamino)titanium (TDMAT) was used as a titanium source, water was used as an oxygen source, and the temperature of the titanium source was 80°C. The electrode was placed in a reaction chamber at 150°C, the pulse time of the titanium source was 0.1s, the pulse time of the oxygen source was 0.02s, and the growth thickness was controlled by the number of ALD cycles to 3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com