Steel pipe column concrete pouring tool and method for house building municipal engineering

A steel pipe column and concrete technology, which is applied in construction, building structure, and construction material processing, can solve the problems of concrete sputtering, etc., and achieve the effects of weakening sputtering, increasing the range of discharge, and facilitating blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

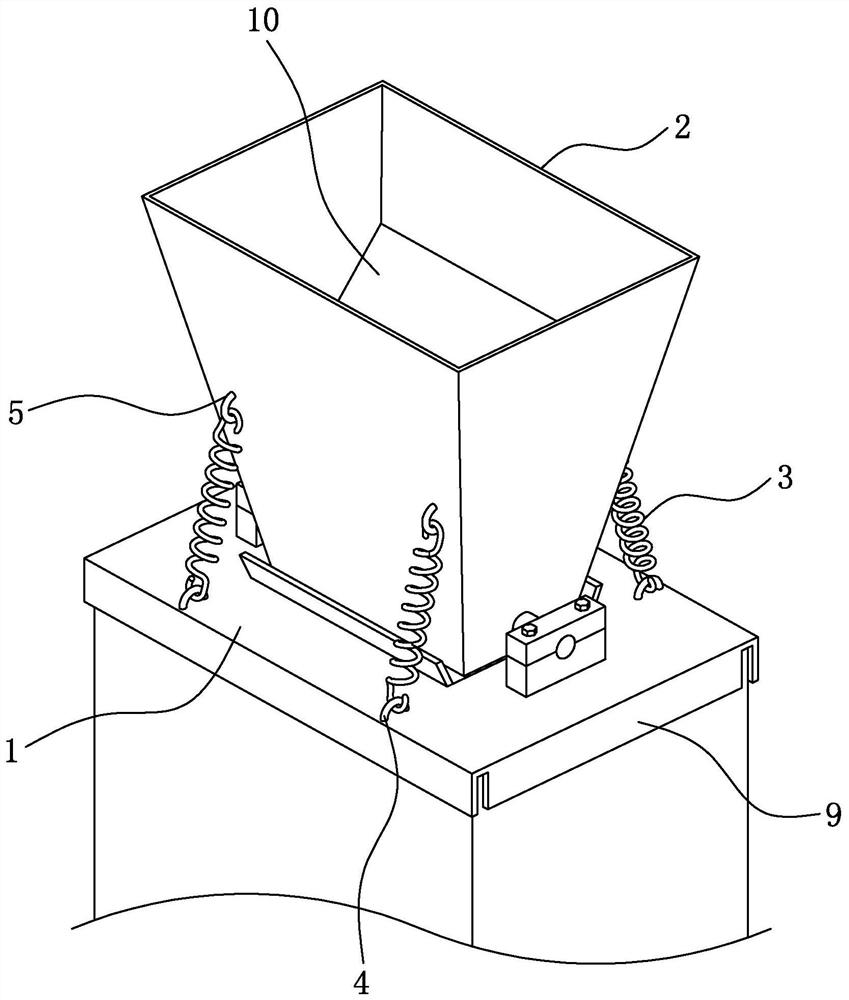

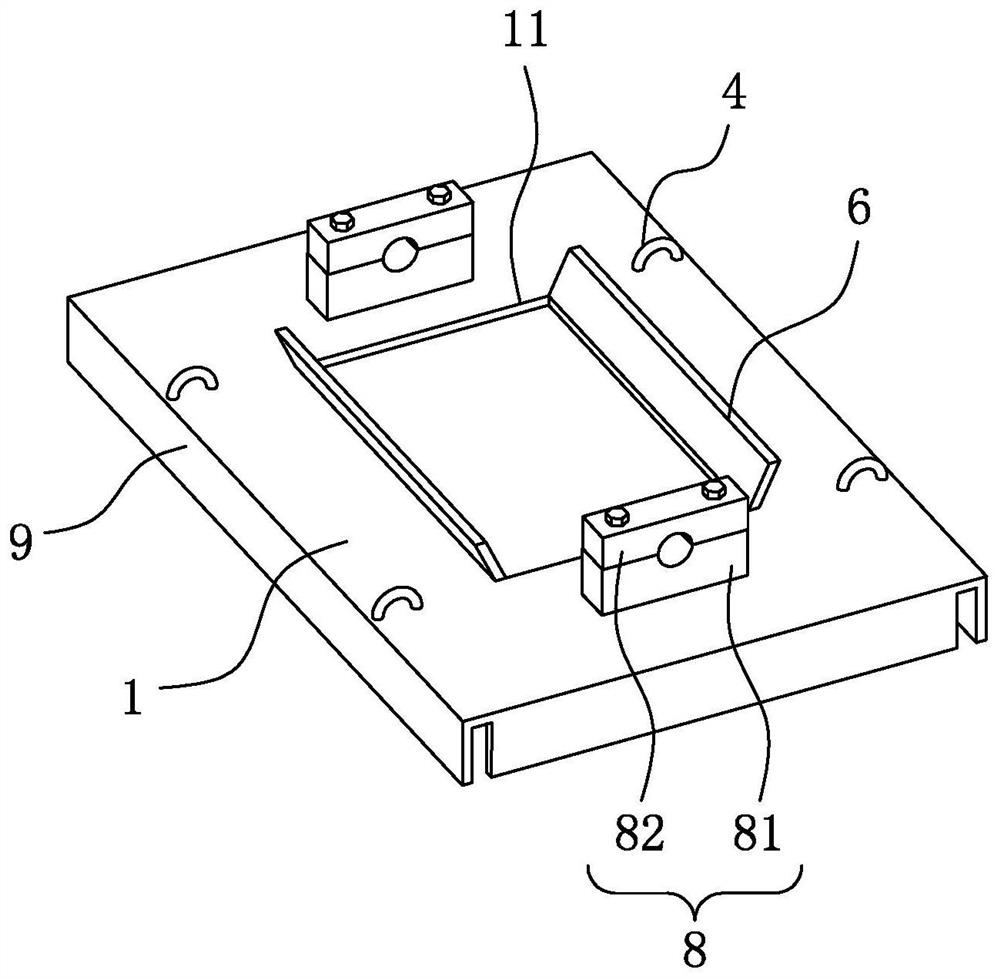

[0045]Referfigure 1 withfigure 2 The steel pipe pouring tool for the housing municipal engineering includes mounting plates 1 mounted at the top opening of the steel pipe column. The mounting plate 1 is positioned with the steel pipe column, and the surface of the mounting plate 1 is opened 11, the mounting plate 1 On the side, a tapered funnel 2 is mounted, the discharge port of the funnel 2 is disposed opposite the grouting port 11, and after being injected into the funnel 2, the concrete can pass through the discharge port of the funnel 2, into the grouting port 11 , Pouring concrete towards the steel tube column.

[0046]Referfigure 1 The edge of the mounting plate 1 is fixed at the same side positioning plate 9 in the mounting plate 1, and there is a certain gap between the positioning plates 9, facilitating the set of positioning plates 9 and the steel pillar. When the mounting plate 1 is mounted with the steel pipe post, the positioning plate 9 and the outer wall of the steel pi...

Embodiment 2

[0055]ReferFigure 4 , The steel pipe column concrete pouring method for housing construction municipal engineering includes the following steps.

[0056]S1: Select the mounting plate 1, which is possible to position the mount 1 set on the steel pipe post.

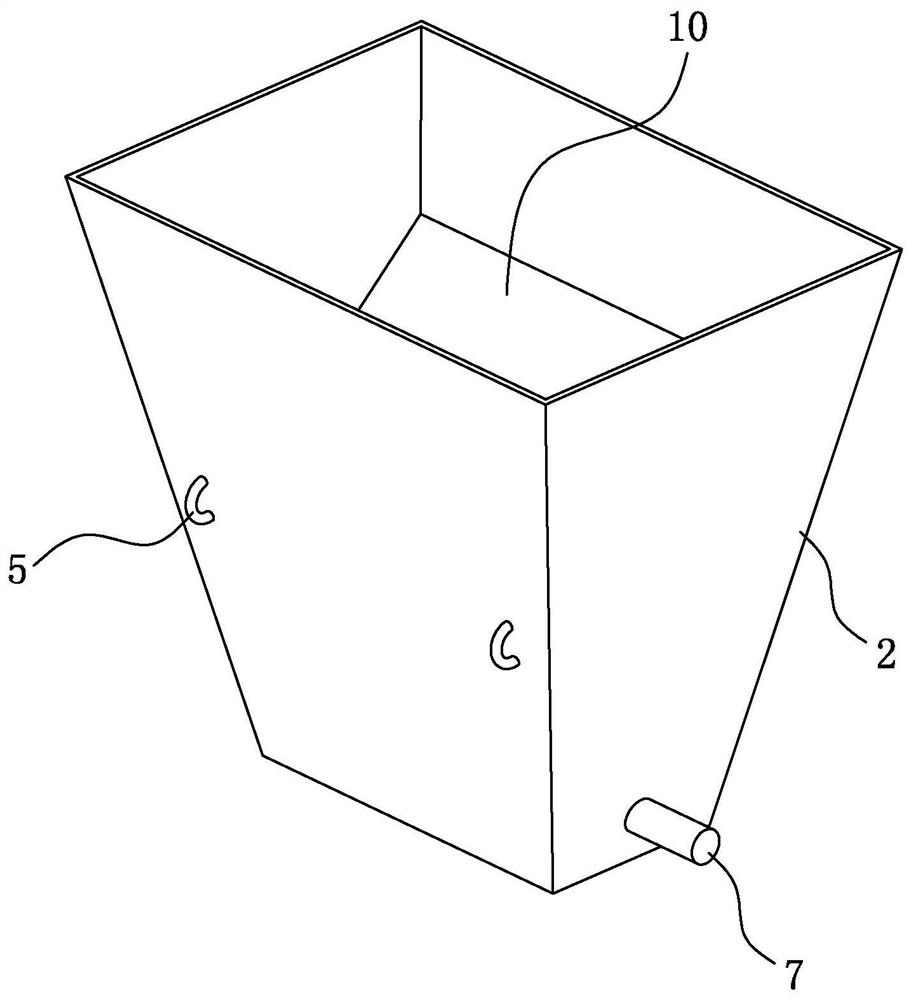

[0057]S2: On the support holder 81 of the mounting plate 1 by the rotation shaft 7, the compressor 82 is fixed to the support seat 81 by bolt, and the rotational relationship of the funnel 2 and the mounting plate 1 is realized, and the spring is hooked. On the second hanging ring 5 on the first hanging ring 4 on the mounting plate 1, a stable connection of the funnel 2 and the mounting plate 1 is realized.

[0058]S3: The mounting plate 1 with funnel 2 is hoisted to the top of the steel pipe, and the mounting plate is set on the top of the steel pipe.

[0059]S4: By placing the pump tube into the funnel 2, the pump tube is stabilized into the funnel 2, and the concrete flows from the funnel 2 into the steel pipe column to achieve pouring.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com