Device and method for testing performance of heat regenerator

A technology of testing device and regenerator, which is applied in the direction of measuring device, testing of machine/structural components, instruments, etc., can solve the problems of inability to meet the experimental conditions of regenerator, high experimental cost, etc., and achieve simple structure, low cost, Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

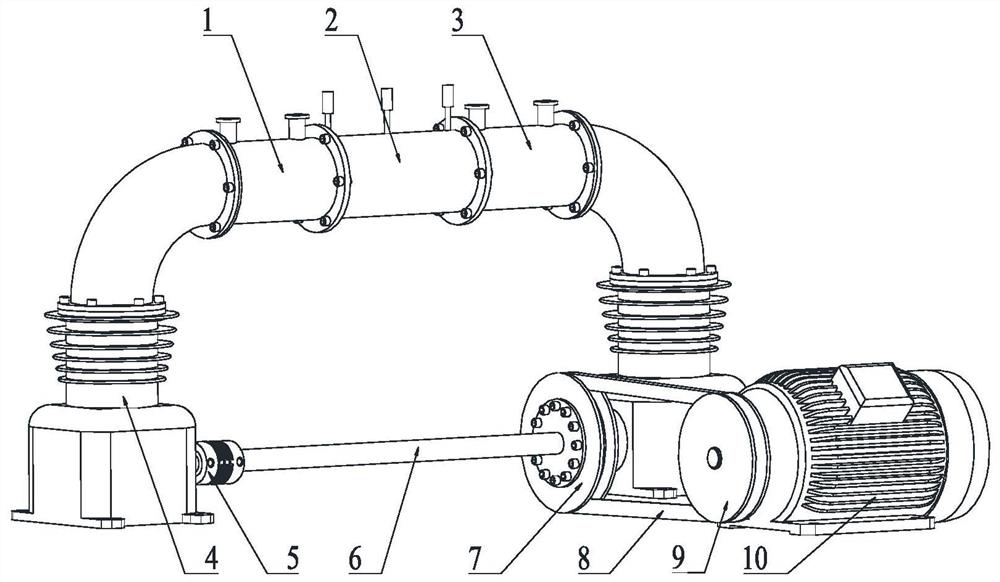

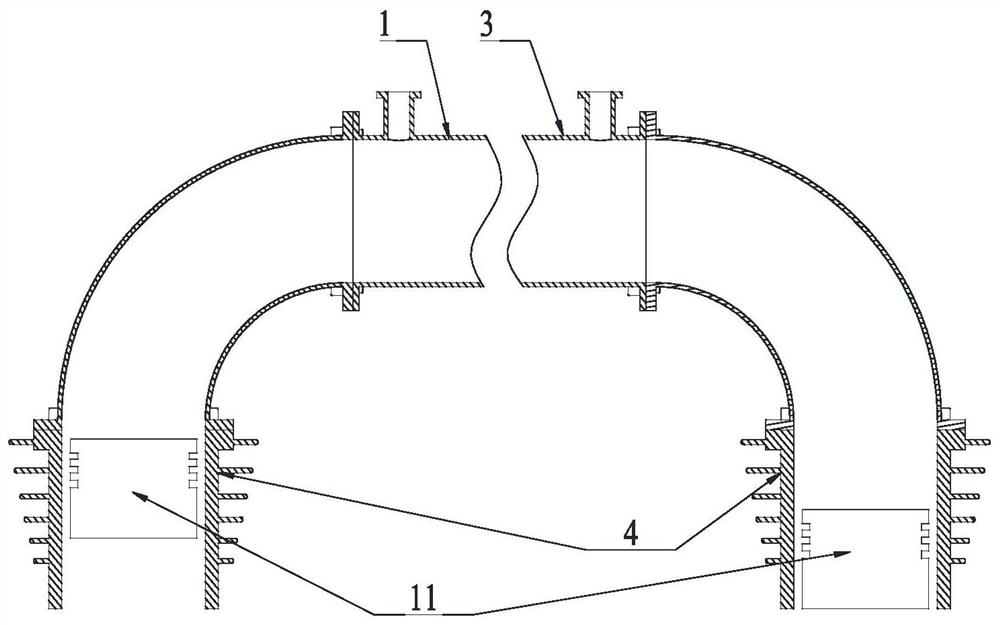

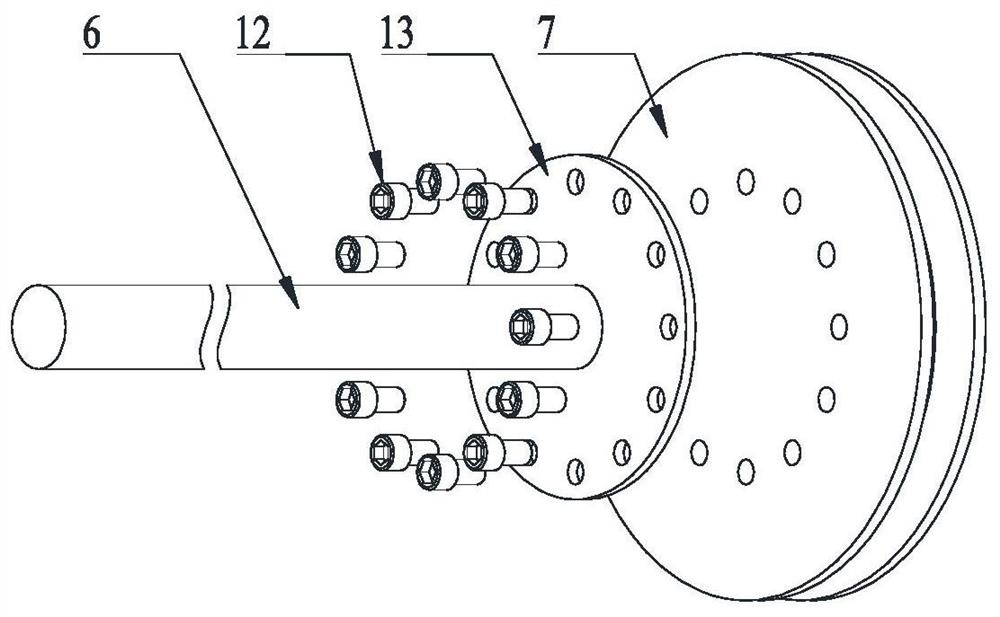

[0028] Such as figure 1 As shown, the regenerator performance testing device of the present invention includes a power source, a piston phase angle adjustment device, a regenerator packaging shell 2, a heater 1 and a cooler 3; wherein the heater 1 and the cooler 3 are tube shells Type heat exchanger, there are connecting flanges on both sides of the shell and tube heat exchanger, such as Figure 4 As shown, two heat exchanger inlet and outlet joints 14 are respectively provided on the outer sides of the side walls of the heater 1 and the cooler 3, and the regenerator packaging shell 2 is arranged between the heater 1 and the cooler 3, and passes through The flanges provided at both ends are respectively connected to the heater 1 and the cooler 3, such as Figure 5 As shown, the regenerator packaging shell 2 is provided with a regenerato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com