Waterproof construction method for planted roof post-cast strip

A construction method and technology of post-pouring tape, which is applied in the direction of roof, roof drainage, roof covering, etc., can solve the problems of post-pouring tape, such as large water seepage, poor waterproof effect, and low manual installation efficiency, and achieve good water-stopping effect and welding Fast, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039]Example 1

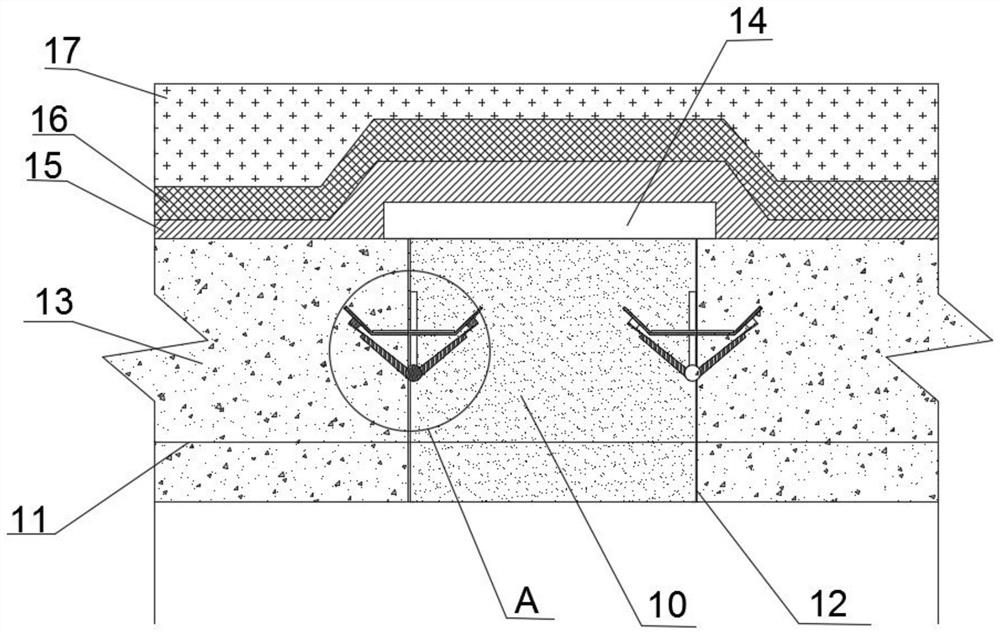

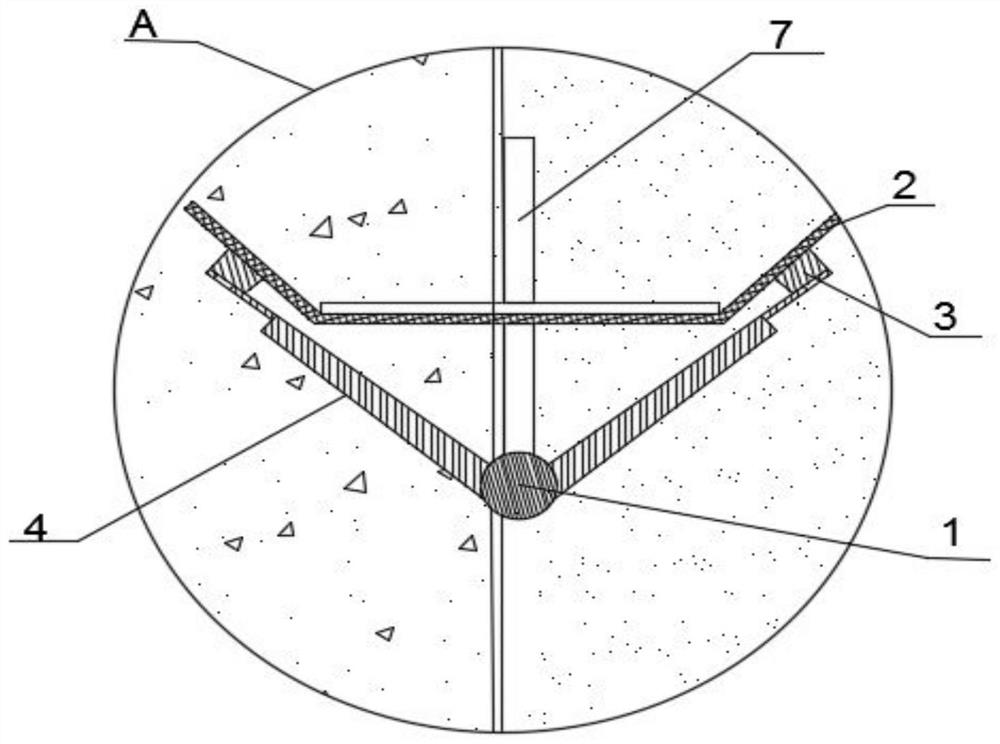

[0040]Such asFigure 1 to 5As shown: is an embodiment of the present invention, a waterproof construction method of planting a rear ladle, including the following steps:

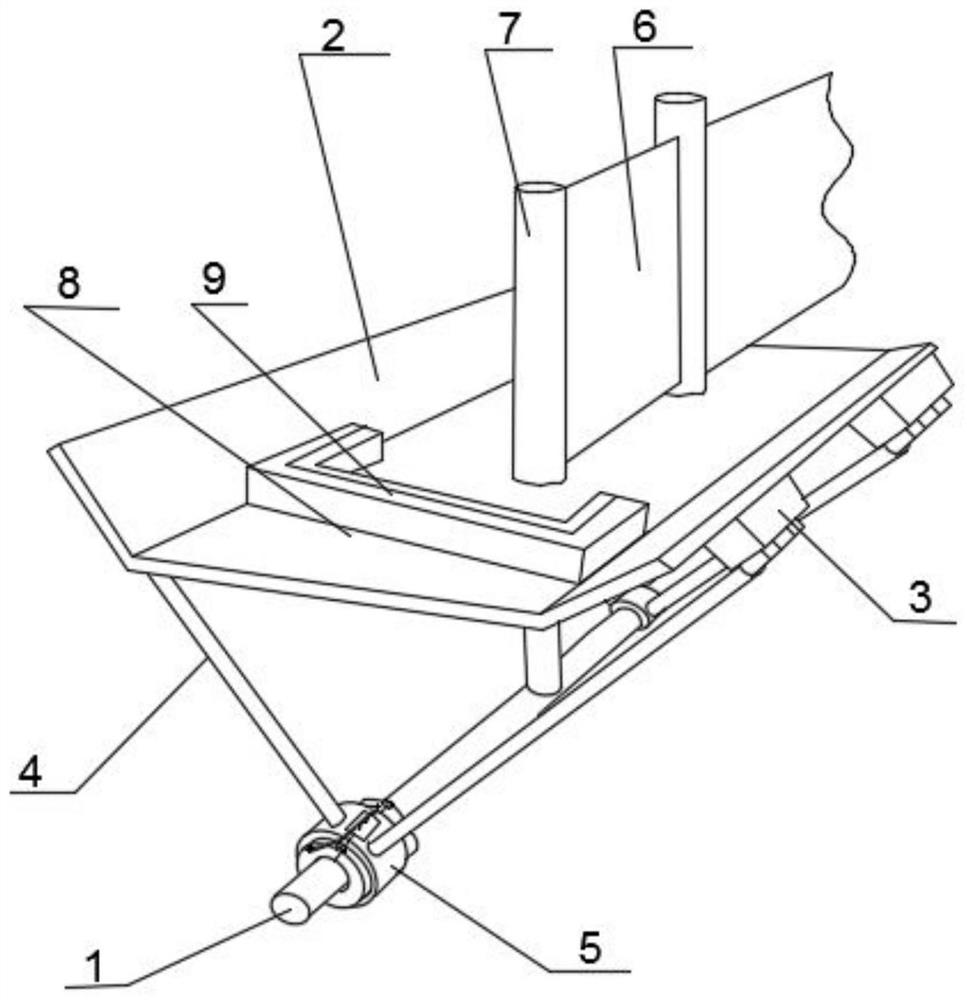

[0041]Step, the soil steel plate 2 is placed on the support reinforcing bar 1, the bottom of the soil steel plate 2 is welded, and the connecting block 3 is opened back to the side of the sided steel plate 2;

[0042]Step 2, the open water plate 2 rolled toward the direction of the welding surface, and the positioning hole 55 of the reinforcing bar 4 is positioned in the positioning hole 55 of the reinforcing bib 4, and the other end of the positioning the reinforcement is mounted;

[0043]Step three, set the mounting hole 51 and the welding isolation layer 52 in the welding case 5, and the mounting hole 51 passes through the support reinforcing bar 1, the welding spacer 52 is adapted to weld the positioning reinforcement 4 and the support reinforcement 1, and the electric slag pressure welding. , The electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap