Control system of heat exchanger, heating furnace and water outlet temperature control method of heating furnace

A heat exchanger and control system technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as inability to obtain domestic water, and achieve the effect of avoiding high temperature burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

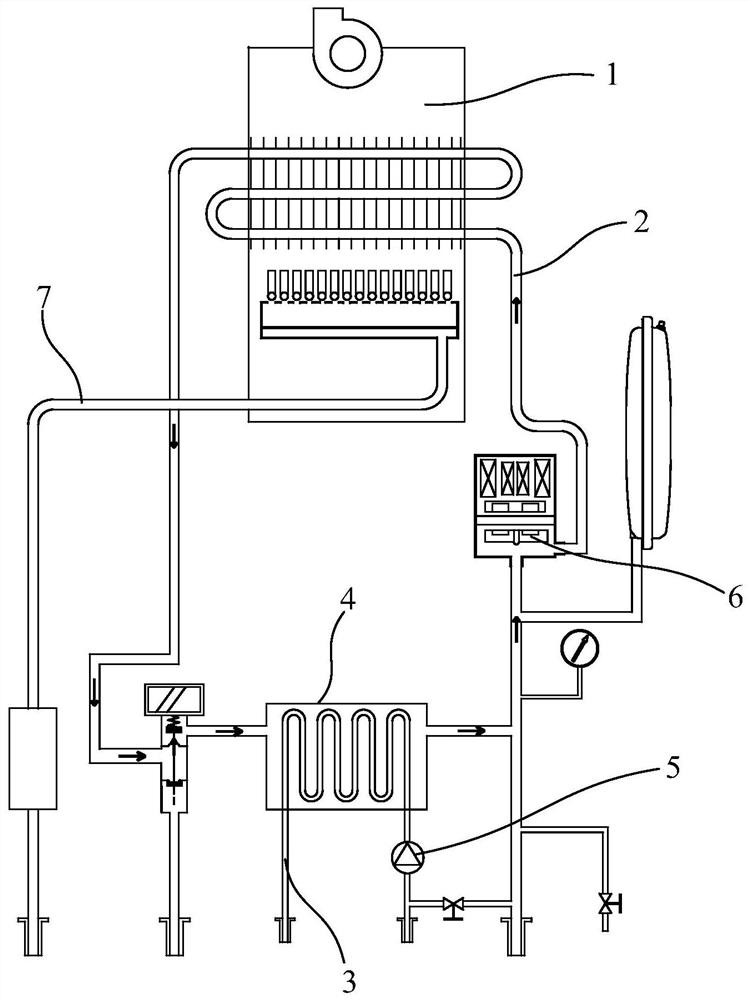

[0101] Such as figure 1 As shown, this embodiment discloses a heating furnace, which includes a heating furnace body 1, a heating water channel 2, a domestic water channel 3, a heat exchanger 4 and a controller, the heating water channel 2 and the heat exchanger 4 The heat source cavity is connected, and the domestic water channel 3 is connected with the heat exchange cavity of the heat exchanger 4 . The heat exchange efficiency of heat exchanger 4 can be regulated by following heat exchanger control system, and the control system of this heat exchanger is used for regulating the heat exchange efficiency of heat exchanger, and this control system comprises heat exchanger and control The controller is connected with the heat exchanger, and the heat exchanger is used for heat exchange between the heat source fluid and the heat exchange fluid. The water in the heating water channel 2 is driven to circulate in the pipeline by the water pump 5 and heated in the heating furnace bod...

Embodiment 2

[0136] Such as Figure 8-9 As shown, the heat exchanger body 100 of this embodiment is substantially the same as that of Embodiment 1, except that the driving mechanism for controlling the circumferential movement of the sealing member 300 in the first fluid channel 101 is different. The driving mechanism in this embodiment includes an electromagnetic attraction mechanism 400 and a valve stem 401 , one end of the valve stem 401 is connected to the seal 300 , and the other end of the valve stem 401 is connected to the electromagnetic attraction mechanism 400 .

[0137] The axial movement of the sealing member 300 in the first fluid channel 101 is controlled by the electromagnetic attraction mechanism 400 , and the structure is simple. During specific control, the magnitude and direction of the magnetic force are changed by changing the magnitude and direction of the current flowing through the electromagnetic coil inside the electromagnetic attraction mechanism 400 , thereby dr...

Embodiment 3

[0139] The heat exchanger body 100 of the plate heat exchanger of this embodiment is substantially the same as that of Embodiment 1, except that in this embodiment, the heat exchange efficiency of the plate heat exchanger is changed by changing the heat source fluid flowing into the heat exchanger. The flow is adjusted.

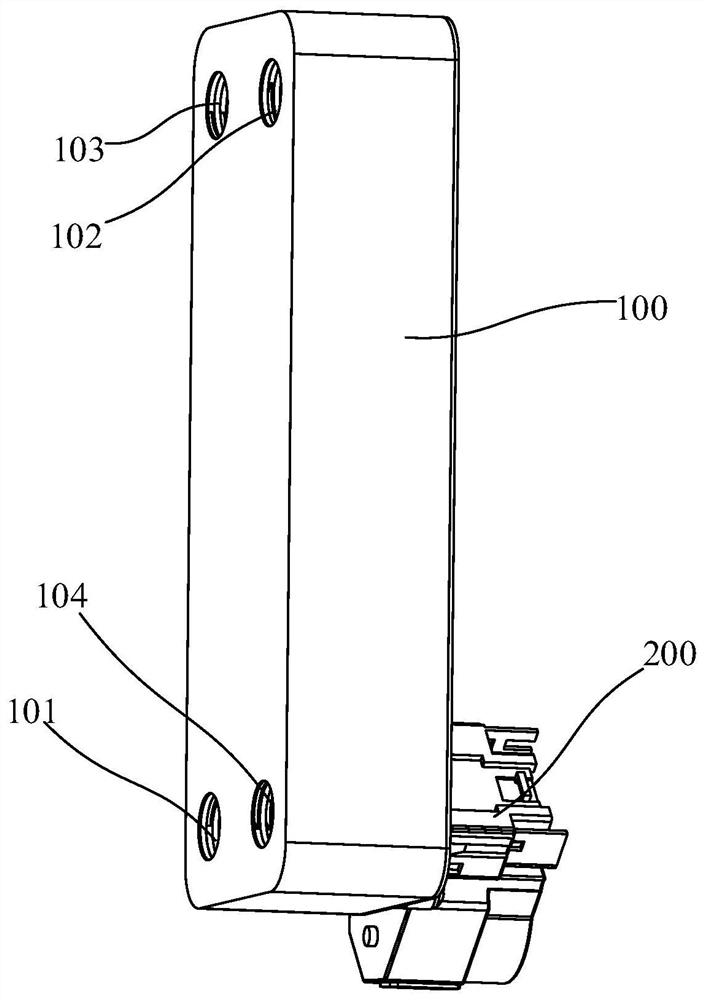

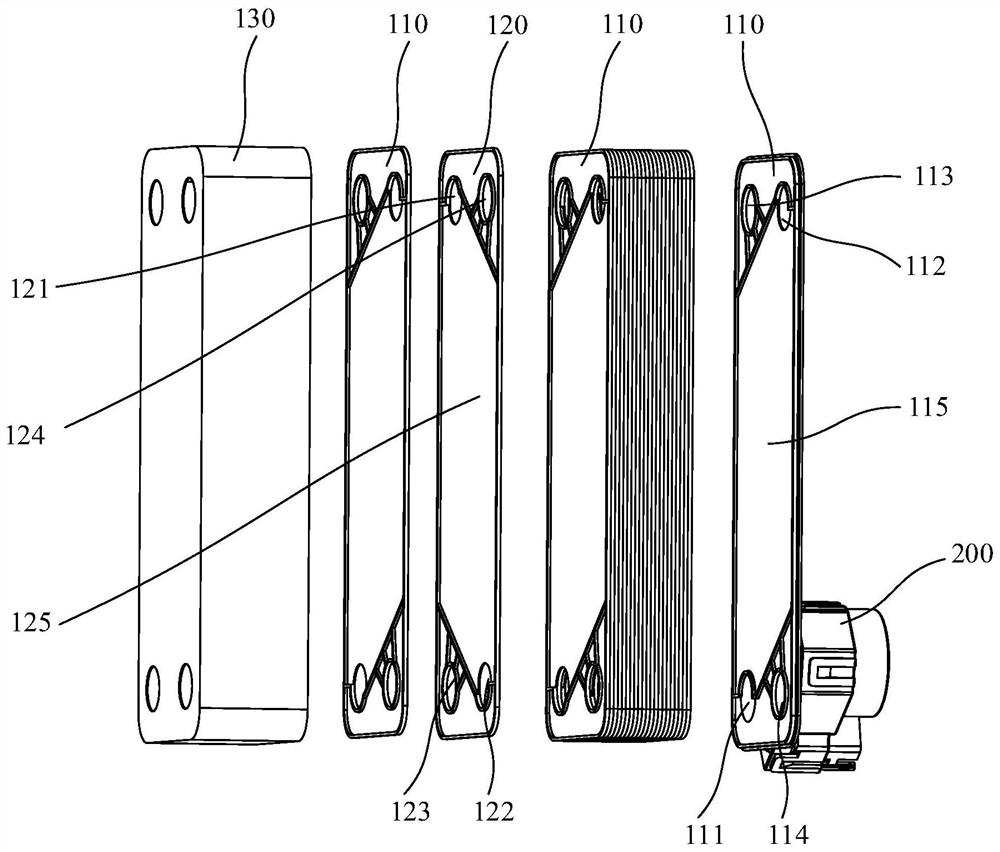

[0140] Such as figure 2 , image 3 , Figure 10 and Figure 11 Shown is a plate heat exchanger of this embodiment, which includes a heat exchanger body 100 , a seal 300 and a driving mechanism for driving the seal 300 to rotate. The heat exchanger body 100 includes a plurality of first heat exchange plates 110, a plurality of second heat exchange plates 120 and a housing 130, the first heat exchange plates 110 and the second heat exchange plates 120 are arranged at intervals in the housing 130, the second The sides of one heat exchange plate 110 and the second heat exchange plate 120 have a first groove 115 and a second groove 125 respectively, and the t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap